Packaging shaping method of bagging fosb by ultrasonic sealing

A technology of ultrasonic wave and sealing device, which is applied in the field of bagging FOSB packaging shaping, can solve the problems of low automation and low efficiency, and achieve the effect of high automation, high efficiency and close cooperation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

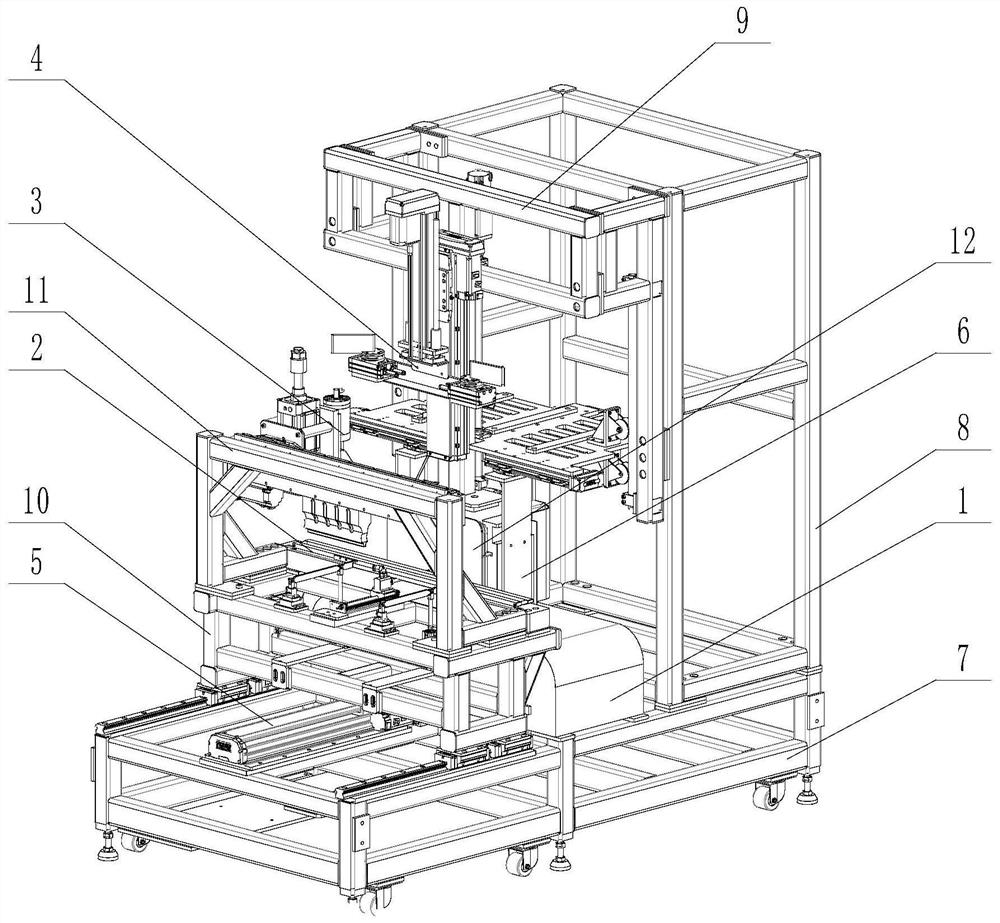

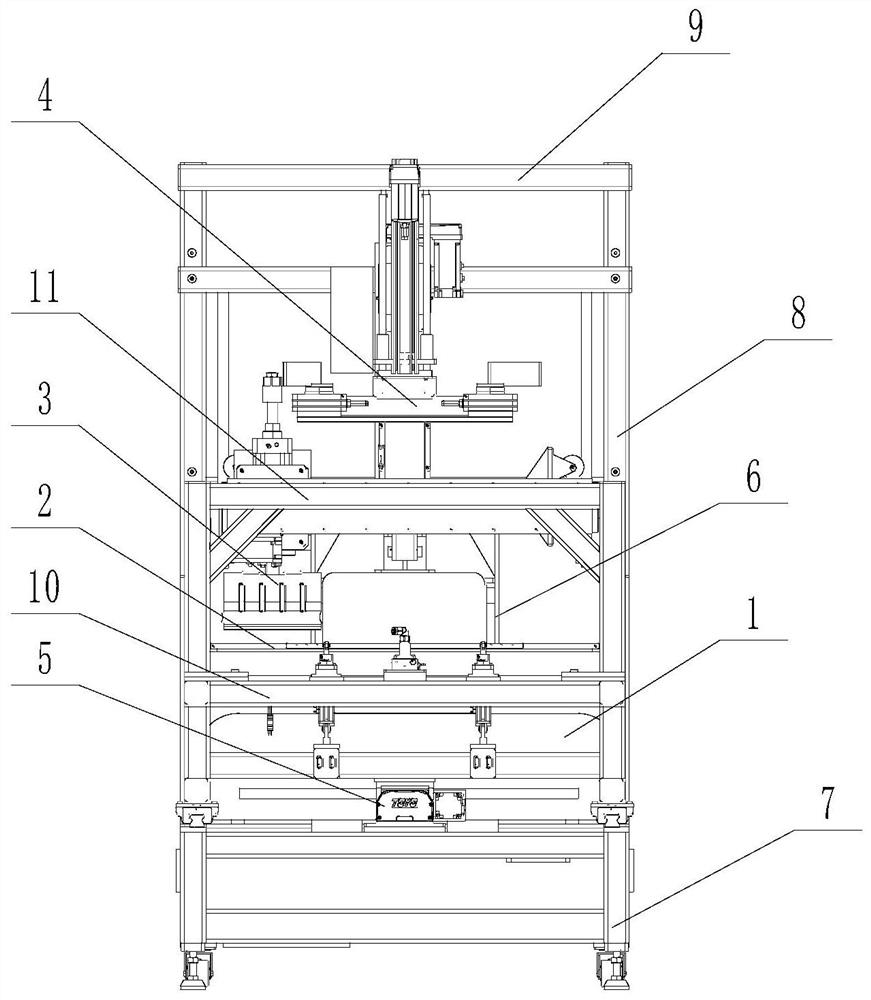

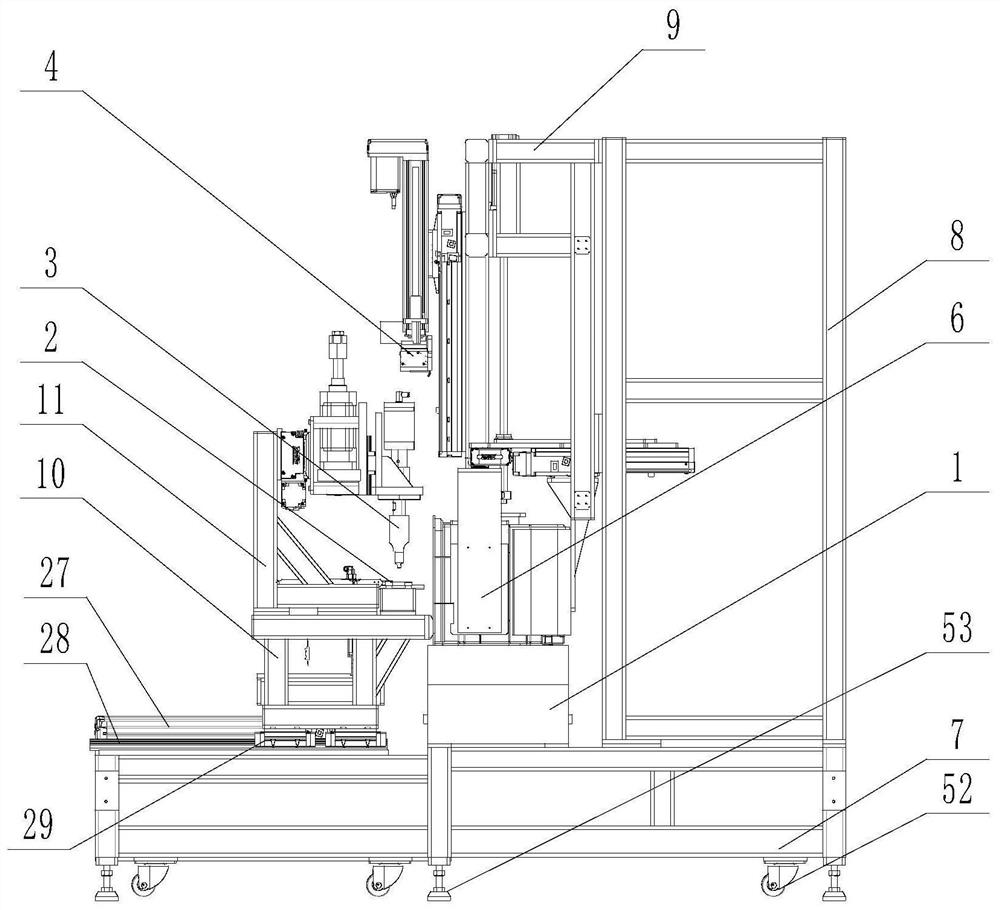

[0052] The present invention will be further described below in conjunction with the accompanying drawings:

[0053] like Figures 1~10 As shown in the figure, a packaging and shaping method of bagging FOSB using ultrasonic sealing is used for shaping the packaging bag outside the FOSB with the packaging bag. The two sides of the FOSB are divided into a protruding side front side and a side back side, the two side back sides are connected with the back side, and the two side front sides are connected with the front side. The packaging shaping method specifically includes the following steps:

[0054] Step 1: The FOSB conveyor belt 1 sends the FOSB12 with the bag mouth in the open state after bagging to the shaping station;

[0055] Step 2: The whole composed of the horizontal driving device 5 of the sealing station and the clamping device 2 and the ultrasonic sealing device 3 moves to the front of the FOSB until the vacuum splint 17 of the clamping device 2 is located under ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com