Horizontal well automatic water controlling well completion pipe column structure

A technology for completion string and horizontal well, which is applied in wellbore/well components, production fluids, earth-moving drilling, etc., can solve problems such as inability to effectively maintain oil production rate, achieve simple and easy construction, and improve oil production rate, without the effect of post-management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

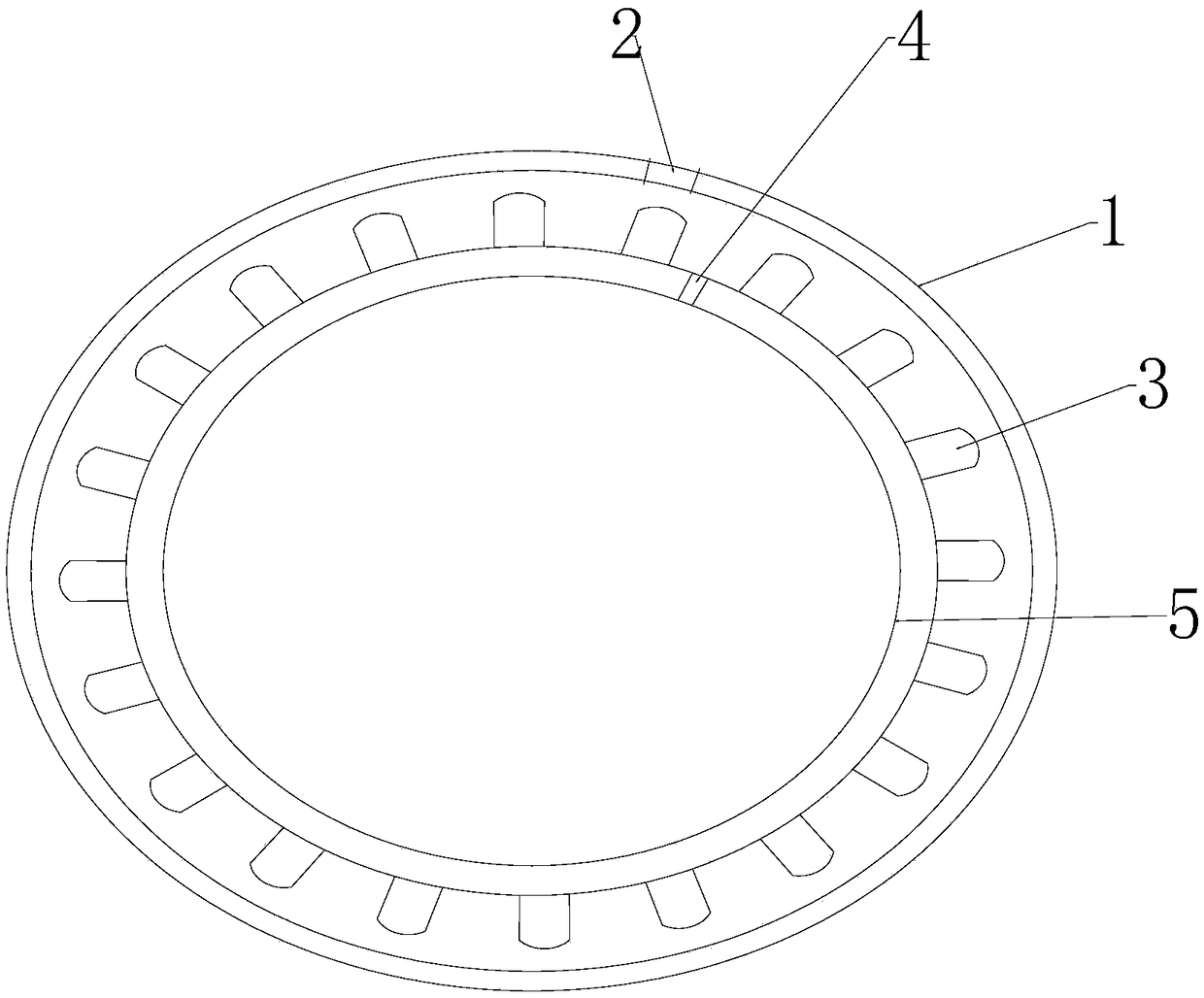

[0021] like figure 1 As shown, a horizontal well automatic water control completion pipe string structure includes a perforated outer pipe 1, a perforated inner pipe 5, and a plurality of water-swellable rubber columns 3 evenly arranged on the outer wall of the perforated inner pipe 5. The concentric shaft of the outer tube 1 is set outside the perforated inner tube 5 and has an appropriate distance from the perforated inner tube 5. The perforated outer tube 1 is evenly provided with a plurality of first perforations 2 along its outer wall. A plurality of second perforations 4 are uniformly arranged on the inner tube 5 along the outer wall, and the plurality of water-swellable rubber columns 3 are independent from each other.

[0022] The position of the first perforation 2 corresponds to the position of the water-swellable rubber column 3 one by one, and the opening of the first perforation 2 matches the shape of the column head of the water-swellable rubber column 3 .

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com