Inner and outer packaging all-in-one machine

An all-in-one machine and inner bag technology, applied to packaging machines, packaging, liquid materials, etc., can solve the problems of slow efficiency and unsatisfactory automatic packaging, and achieve the effect of simplifying control procedures, reducing adverse phenomena, and reducing the number of driving mechanisms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

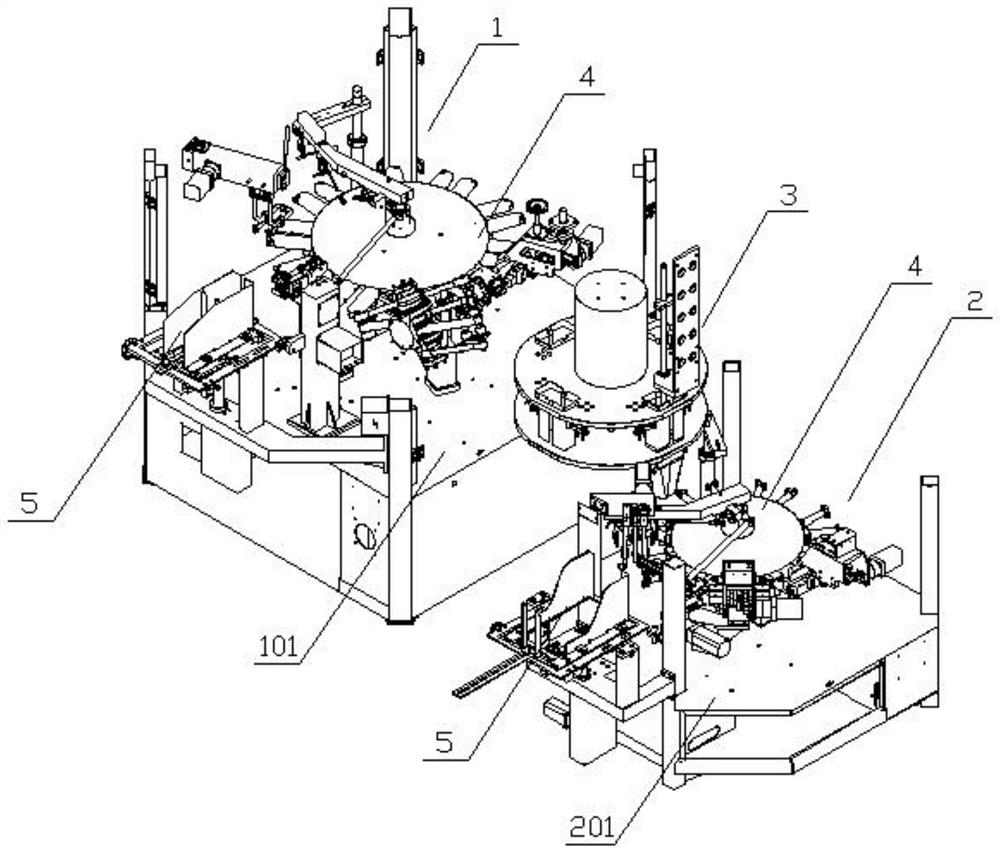

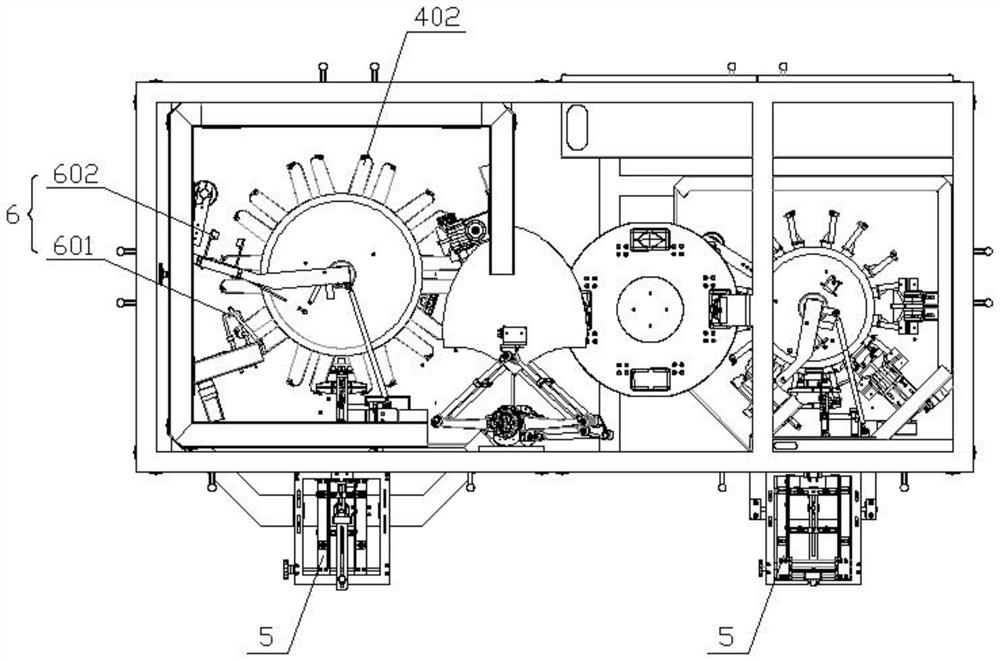

[0032] Example 1, as Figure 1-4 As shown in the figure, the structure of this embodiment is: an inner and outer bag integrated machine, which includes an inner bag packaging part 1 and an outer bag packaging part 2 and a transfer part 3 between them; 1. The filled inner bag is moved to the outer bag packaging part 2 for the subsequent process of packing the inner bag into the outer bag. The inner bag packaging part 1 includes an inner packaging workbench 101, and the outer bag packaging part 2 It includes an outsourcing workbench 201, and both the inner packaging workbench 101 and the outsourcing workbench 201 are provided with a bagging mechanism 4.

[0033] The bagging mechanism 4 includes a rotating ring 401 that rotates along a vertical axis. The rotating ring 401 is provided with a clamping group for clamping the edges of both sides of the packaging bag, and the clamping group includes horizontally spaced clamping jaws. 402, the distance between the clamping jaws 402 on...

Embodiment 2

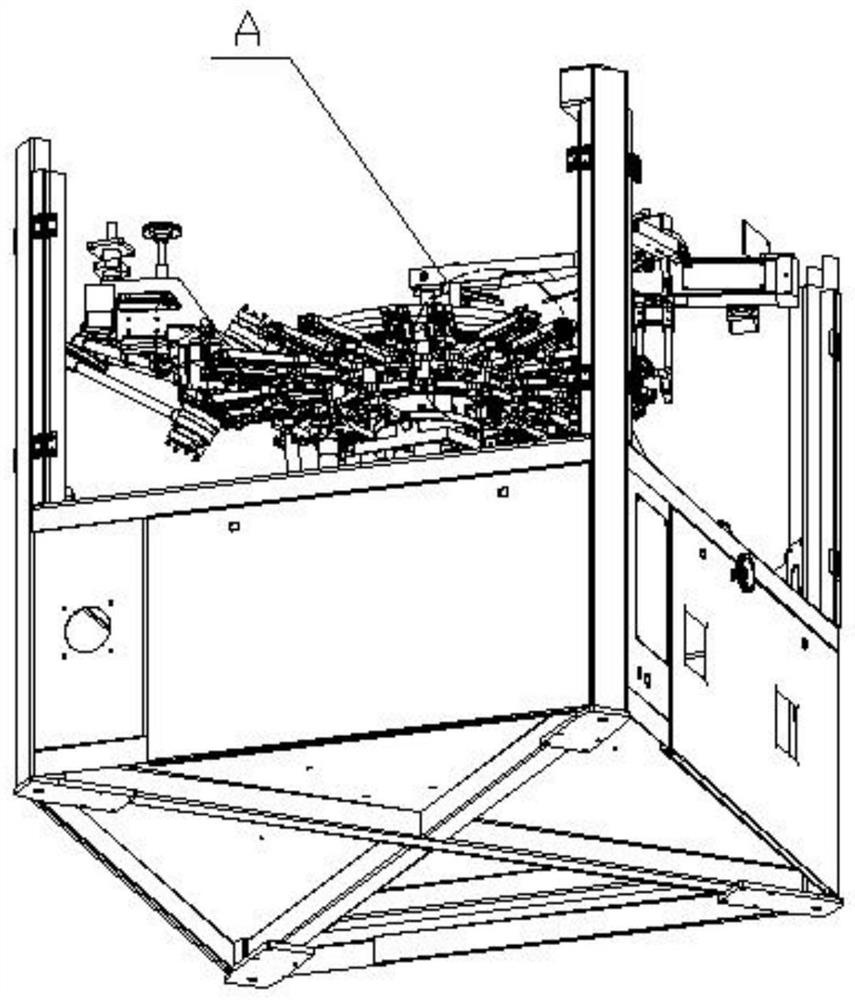

[0037] Example 2, as Figure 7-8 As shown, other structures and working methods of this embodiment may refer to Embodiment 1, but in this embodiment, the rotating ring 401 includes a top plate 408 and a rotating ring 409 spaced from top to bottom, and the rotating ring 409 covers It is located on the outside of the inner ring 403, the top plate is located above the inner ring 403, the inner ring 403 is installed on the inner working table 101 and the outer working table 201, the rotating ring 401 is rotatably matched with the inner ring 403, and the rotating ring 401 can be driven by a motor , hydraulic and other drives, the upper end surface of the inner ring 403 is provided with a boss portion 4031, and the area of the boss portion 4031 is adapted to the positions of the bag supply device 5, the coding station and the heat sealing station.

[0038] The rotating ring 401 is provided with a rotating shaft 4011, the opposite sides of the two clamping claws 402 on the same cla...

Embodiment 3

[0042] Example 3, as Figure 4-9 As shown, other structures and working methods of this embodiment may refer to Embodiment 1 or 2, but in this embodiment, the clamping jaw 402 includes a fixed part 4021 and a movable part 4022, and one end of the movable part 4022 is connected to the fixed part 4021 One end is rotatably connected, the other end of the movable part 4022 is rotatably connected with one end of the L-shaped rocker 4023, the other end of the L-shaped rocker 4023 is rotatably connected with the movable clamping part 4024, and the fixed part 4021 is provided with a connection with the movable part 4022 The clamping spring 4025.

[0043] The inner packaging workbench 101 and the outer packaging workbench 201 are also provided with an empty bag rejection mechanism. The empty bag rejection mechanism is located at the empty bag rejection station and not in the area where the boss portion 4031 is located. The empty bag rejection mechanism includes a vertical direction. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com