Automatic filling device for food production

An automatic filling and food technology, applied in packaging and other directions, can solve problems such as difficult maintenance work, increased procurement costs, and increased employment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

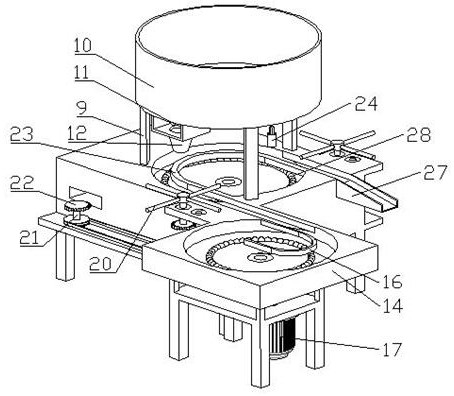

[0016] The present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments.

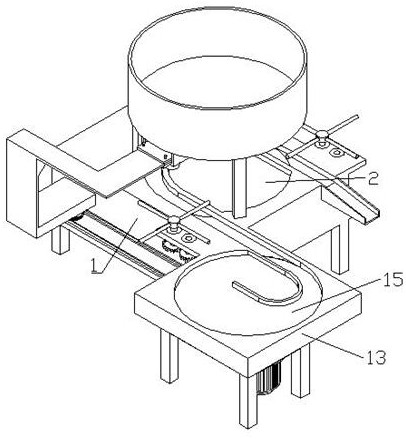

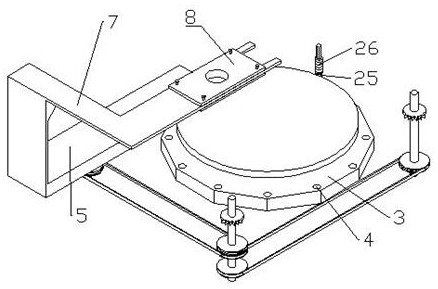

[0017] Such as Figure 1-5 As shown, an automatic filling device for food production, including a support frame 1, an intermittent tray 2, a multilateral turntable 3, a spherical groove 4, a rack frame 5, a push wheel 6, a sliding frame 7, an adjustment partition 8, and a support column 9. Material storage box 10, discharge pipe 11, gathering funnel 12, transmission part 13, the upper part of the support frame 1 is equipped with a horizontal intermittent tray 2 through bearings, and a horizontal multilateral turntable 3 is fixed at the bottom of the intermittent tray 2 A plurality of vertical spherical grooves 4 are equidistantly opened on the top of the multilateral turntable 3, a horizontal rack frame 5 is slidably connected to the left part of the support frame 1, and a horizontal rack frame 5 is installed on the front end of the rack frame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com