Construction method of copper waterstop in anti-seepage system of concrete face rockfill dam

A technology of concrete panels and construction methods, which is applied in water conservancy projects, dams, barrages, etc., can solve the problems of difficult quality control, time-consuming, labor-intensive and material-consuming, and many welding joints, so as to facilitate popularization and use, ensure quality, and reduce installation The effect of the weld

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

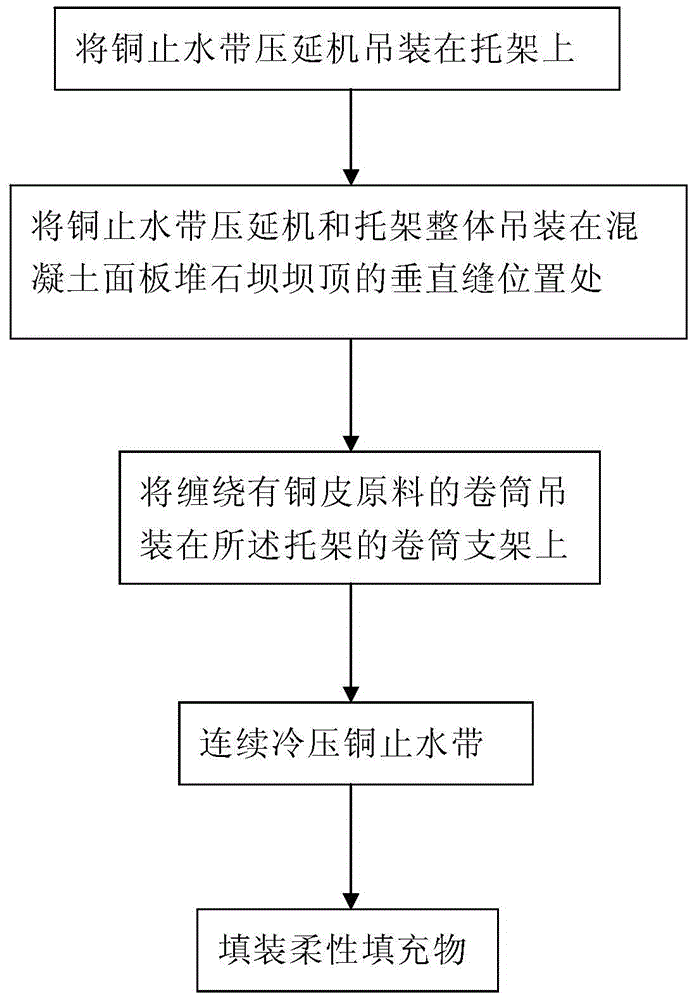

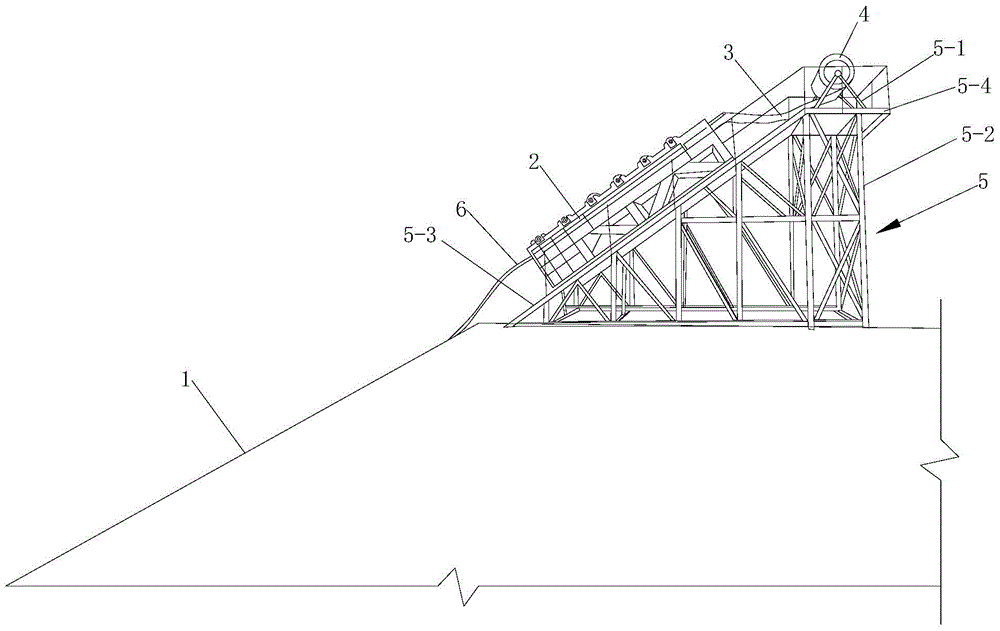

[0037] Such as Figure 1 to Figure 4 The construction method of the copper waterstop in the anti-seepage system of a concrete face rockfill dam shown includes the following steps:

[0038] Step 1, hoisting the copper waterstop calender 2 on the bracket 5;

[0039] Step 2, integrally hoisting the copper waterstop calender 2 and the bracket 5 at the vertical joint position of the concrete face rockfill dam 1 crest (such as figure 2 shown);

[0040] Step 3, hoisting the reel 4 wrapped with the copper sheet raw material 3 on the reel support 5-1 of the bracket 5;

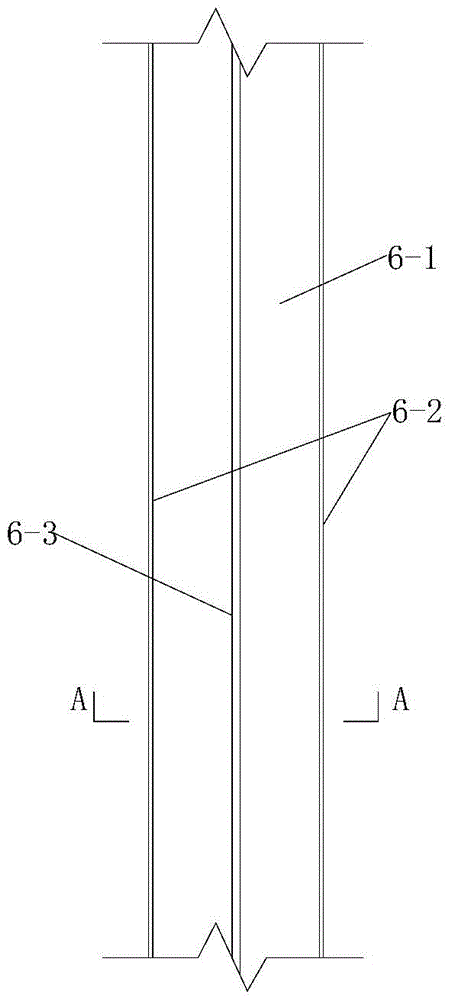

[0041] Step 4, continuous cold-pressed copper waterstop 6: open the copper waterstop calender 2, send the copper skin raw material 3 on the reel 4 into the copper waterstop calender 2, and pass through the copper waterstop The calender 2 continuously cold-presses the copper skin raw material 3 into a copper waterstop 6, the copper waterstop 6 includes a bottom plate 6-1, and both sides of the bottom plate 6-1 are li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com