A special chemical product transportation device

A transportation device and chemical technology, applied in the field of special chemical product transportation devices, can solve the problems of inability to improve the sealing effect, single sealing structure, etc., and achieve the effects of reducing rigidity damage, improving adjustment efficiency, and improving shock absorption and buffer structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0036] as attached figure 1 to the attached Figure 9 shown:

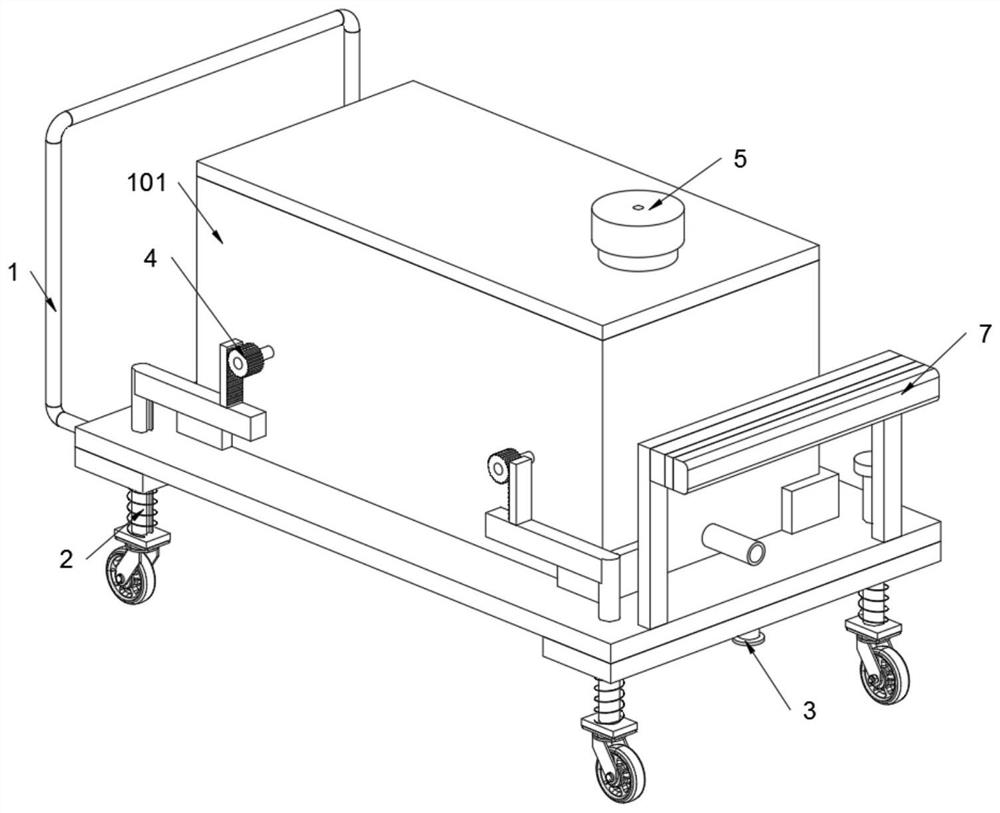

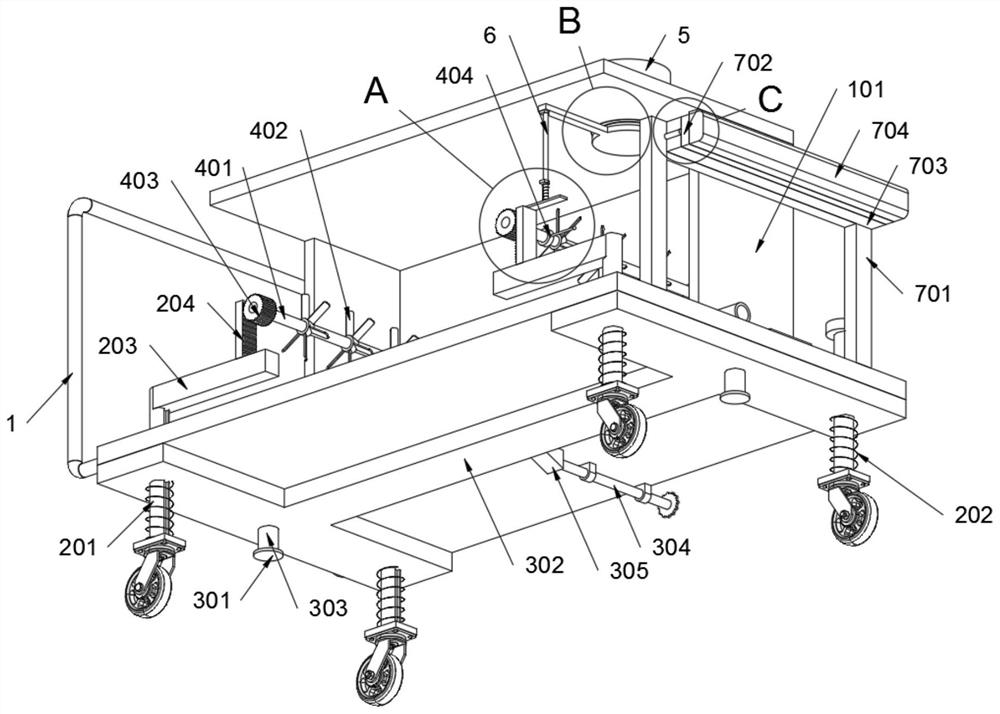

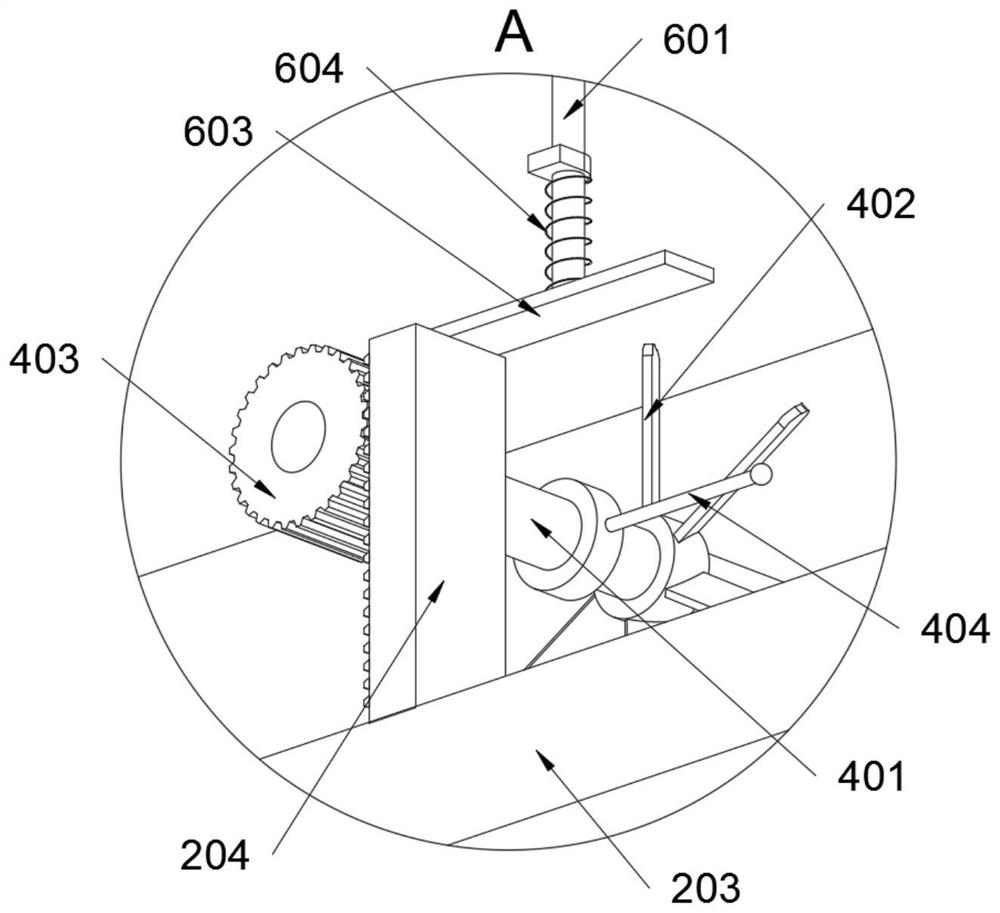

[0037] The present invention provides a special chemical product transportation device, comprising a transportation vehicle main body 1, a sealing cover 502, a sealing block 503 and a force plate 603; a liquid storage tank 101 is fixedly placed on the transportation vehicle main body 1, and the transportation vehicle main body 1 is installed on the transportation vehicle main body 1. There is a shock absorption structure 2, and an adjustment structure 3 is also installed on the bottom end surface of the main body 1 of the transport vehicle; a mixing structure 4 is arranged in the liquid storage tank 101, and a liquid injection port sealing structure 5 is provided on the top of the liquid storage tank 101, and the liquid storage tank is provided with a sealing structure 5. 101 is also provided with a second sealing structure 6; refer to as Figure 9 , the liquid injection port sealing structure 5 includes a sealin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com