Preparation method and processing and trimming equipment of a rubber-polyurethane composite product

A composite product and polyurethane technology, applied in metal processing equipment, manufacturing tools, grinding/polishing equipment, etc., can solve problems such as poor adaptability of trimming devices, affect production quality, increase operating steps, etc., and achieve water resistance and fire resistance High, improve the range of use, and achieve a high degree of self-compensation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

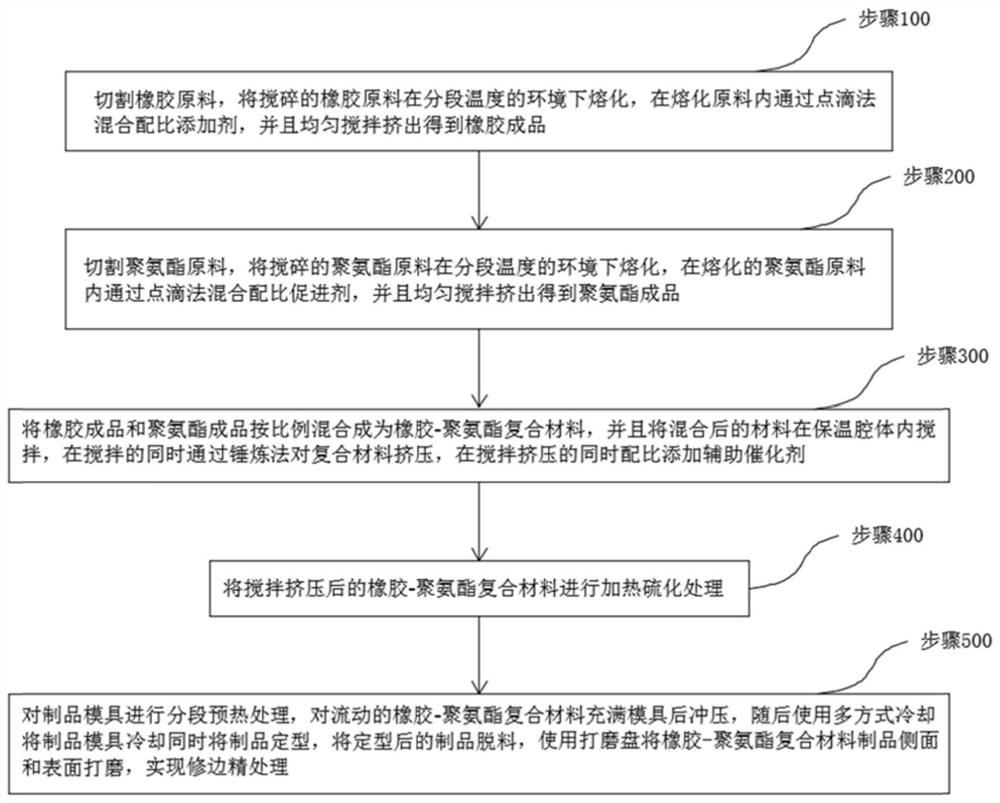

[0055] as attached figure 1 Shown, the invention provides a kind of preparation method of rubber-polyurethane composite product, comprises the steps:

[0056] The first step is to cut and crush the rubber raw material components. The crushed rubber raw materials are melted in a segmental temperature environment, and the additives are mixed and proportioned in the melted rubber raw materials by the drop method, and the rubber products are obtained by uniform stirring and extrusion. In the present invention, the specific mixing ratio of the additive and the rubber raw material is 3 / 20-3 / 10, and the additive is mixed and stirred with the rubber raw material by the drop method, which can improve the mixing uniformity between the additive and the rubber raw material, thereby improving the rubber product. the quality of.

[0057] It should be added that in the present invention, the additives include 10-15wt% accelerator, 15-30wt% pigment, 10-25wt% zinc oxide, 25-40wt% blowing agen...

Embodiment 2

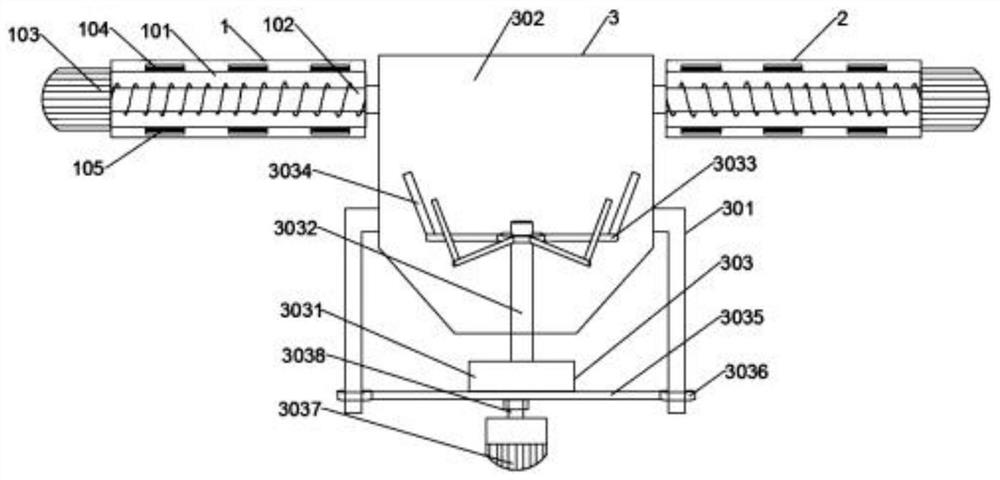

[0078] Based on the above preparation method, the present invention also provides a rubber-polyurethane composite product preparation device, which is composed of a multifunctional mixing device, a product mold and processing and trimming equipment. The multifunctional mixing device is mainly to obtain rubber products and polyurethane products, and then mix and hammer the rubber products and polyurethane products to obtain rubber-polyurethane composite materials, extrude the rubber-polyurethane composite materials into the product mold for stamping and shaping, and shape The completed product is demolded and trimmed to obtain a complete rubber-polyurethane composite product.

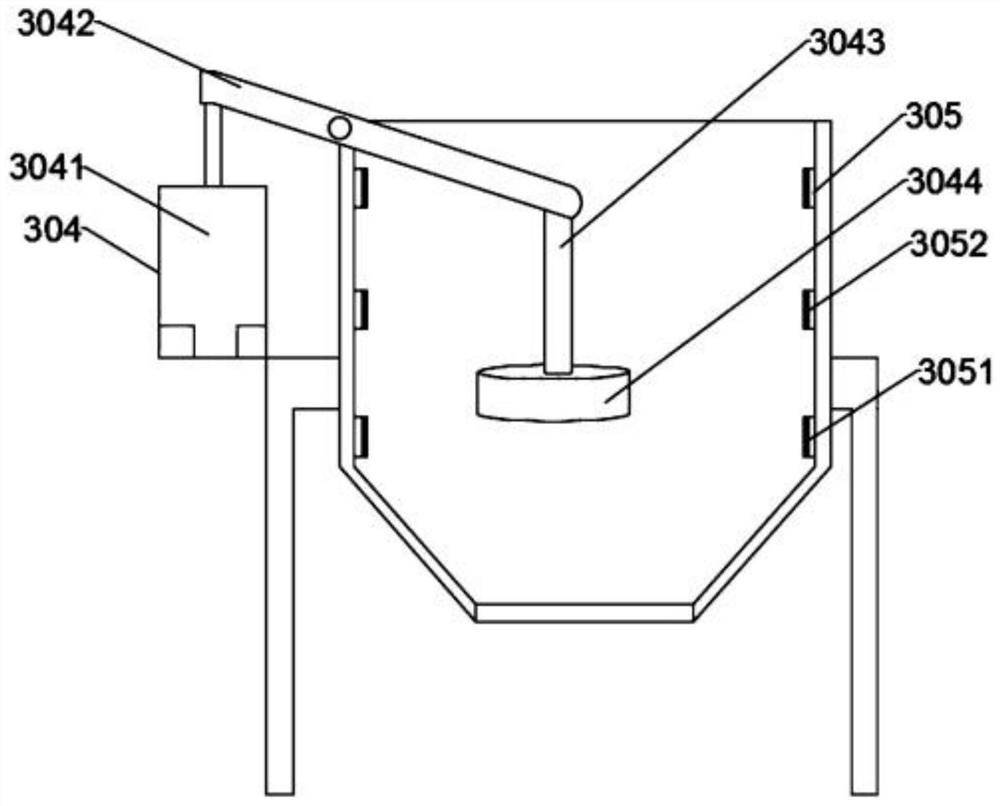

[0079] as attached figure 2As shown, wherein, the multifunctional mixing device includes a rubber melting mechanism 1 and a polyurethane melting mechanism 2, and the rubber melting mechanism 1 and the polyurethane melting mechanism 2 are jointly connected with a secondary extrusion mechanism 3, that is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com