Waste collecting device for textile machine

A waste collection and textile machine technology, which is applied to the parts of strapping machinery, strapping materials, paper/cardboard containers, etc., can solve the problems of incapable of automatic processing, excessive smoke and simple structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

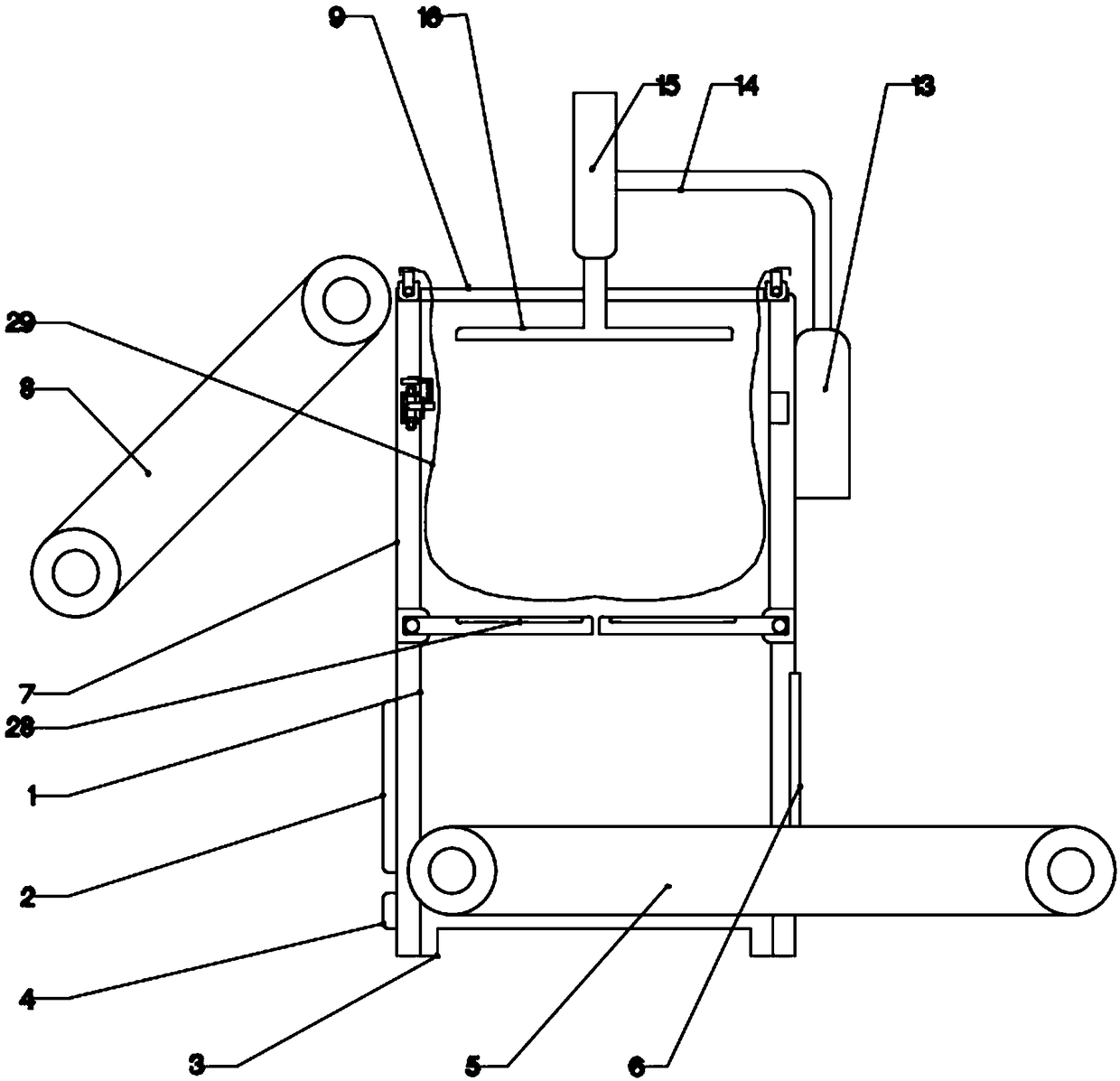

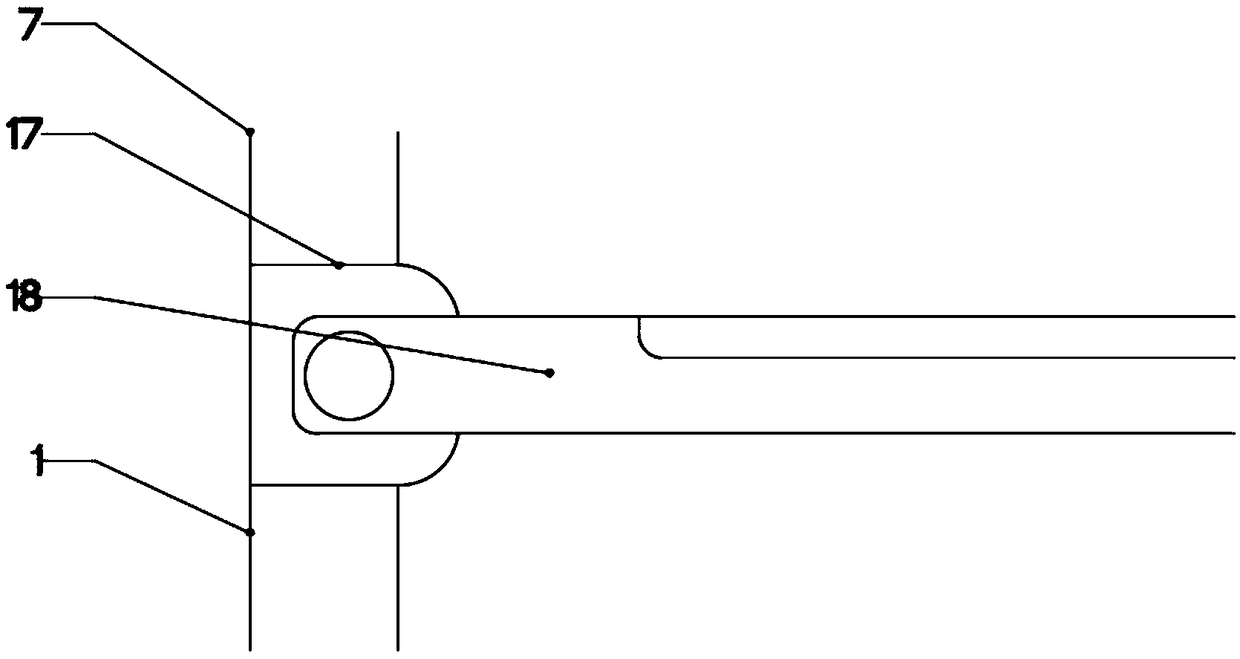

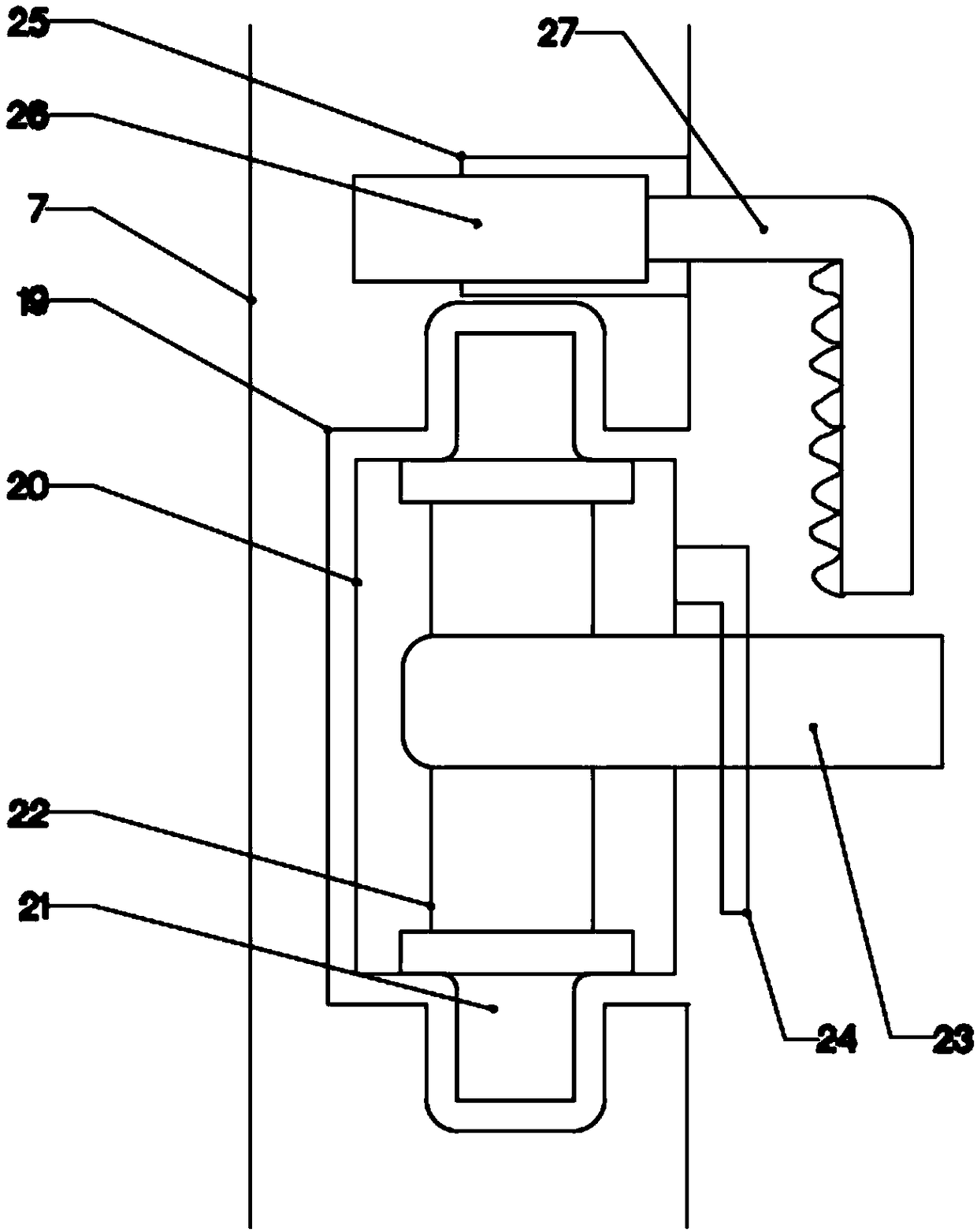

[0019] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-4 shown.

[0020] In this embodiment, the waste materials can be automatically conveyed through the function of the conveying device, so as to achieve the purpose of high automation. Through the function of the compacting device, the waste material can be compressed to the maximum and the work efficiency can be improved. Through the action of the bundling device, the packaging bag can be automatically sealed to achieve the purpose of automatic sealing.

[0021] In the first step, at first the packing bag 29 is fixed on the fixed rod 12, and then the controller 2 controls the conveyor belt one 5 to work, and the conveyor belt one 5 directly transfers the waste to the rectangular box body two 7 and falls into the packing bag 29, At the same time, the controller 2 controls the electronic telescopic rod 13 to expand and contract, and the telescopic end of the elect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com