Forming mold for aluminum-plastic panel

A technology for forming molds and aluminum-plastic panels, applied in the field of forming aluminum-plastic panels, can solve the problems of low safety, difficult to take out, and difficult to demold, and achieve the effect of avoiding operation difficulty, avoiding insufficient hardness and good demoulding effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

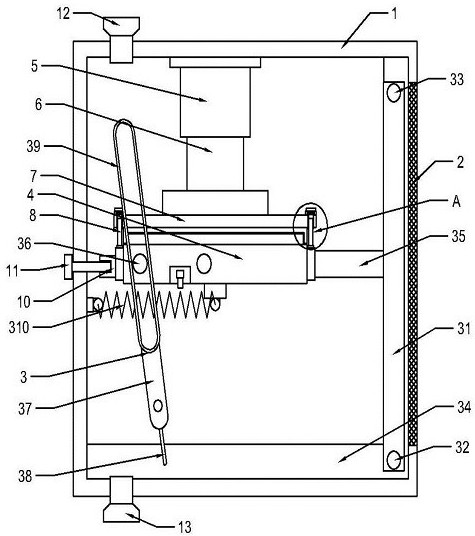

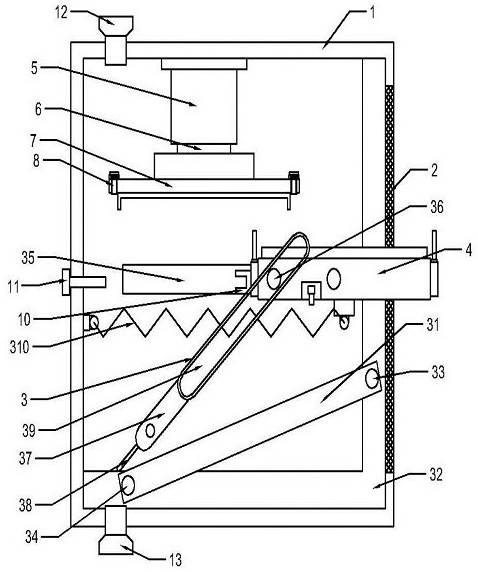

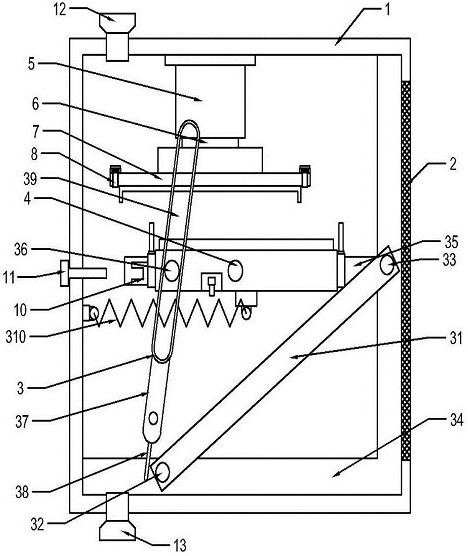

[0051] like figure 1 As shown, in the embodiment of the present invention, the molding die for the aluminum-plastic panel includes:

[0052] A chassis 1, one side of the chassis 1 is provided with a take-out port 2, and the interior of the chassis 1 is provided with an access component 3, and the access component 3 is equipped with a lower template 4, and the access component 3 is used to realize Automatic sealing of the chassis 1 and removal of the lower template 4;

[0053] The liquid injection port 12 and the liquid discharge port 13 are arranged on the chassis 1, and are used to inject cooling liquid into the interior of the chassis 1;

[0054] Pneumatic cylinder 5 is installed inside the cabinet 1. A pneumatic rod 6 is arranged inside the pneumatic cylinder 5. An upper template 7 is installed on one end of the pneumatic rod 6. A clip is arranged between the lower template 4 and the upper template 7. Connecting assembly 8, described clamping assembly 8 is used for making...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com