Yarn feeding device, yarn storage wheel of yarn feeding device and assembly method thereof

An assembly method and a yarn storage wheel technology are applied in textiles and papermaking, knitting, weft knitting, etc., which can solve problems such as increased product defect rate, increased production cost, and exposed burrs, so as to reduce production costs, save man-hours, and avoid The effect of snagging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

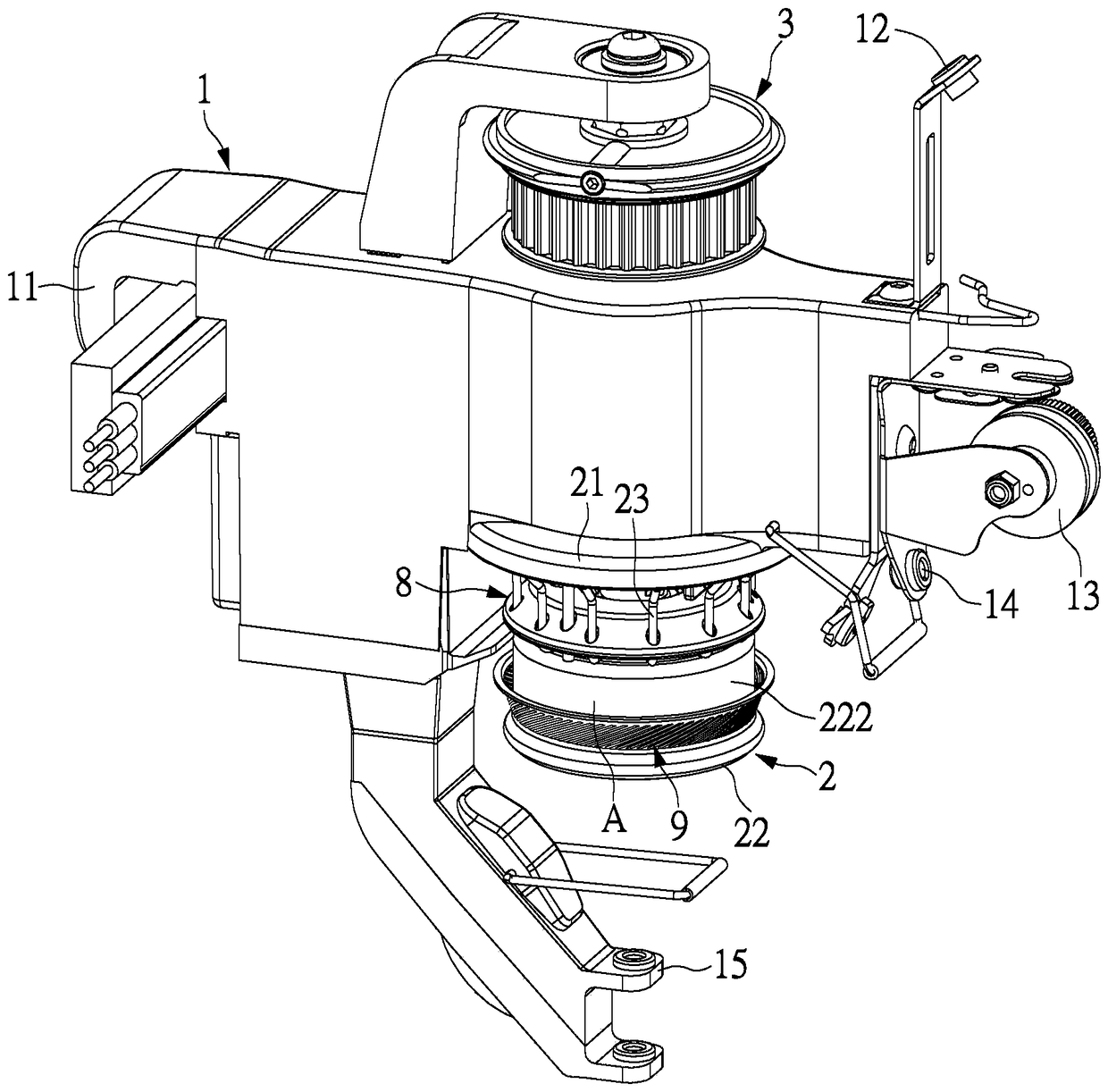

[0067] see figure 1 , the present invention provides a yarn feeding device, the yarn feeding device includes a body 1 and a yarn storage wheel 2, the yarn storage wheel 2 is rotatably connected to the body 1, the yarn storage wheel 2 can be connected to a Pulley 3, the pulley 3 can be used to engage with belt elements such as belts (not shown) to drive the pulley 3 and the yarn storage wheel 2 to rotate, so that the yarn storage wheel 2 drives the yarn to store and send yarn.

[0068] In this embodiment, an electromagnetic clutch type yarn feeding device is disclosed, but it is not limited thereto. The present invention can also be applied to motor type or other types of yarn feeding devices. In another embodiment, it is a motor type The yarn feeding device can utilize a motor (figure omitted) to directly drive the yarn storage wheel 2 to rotate.

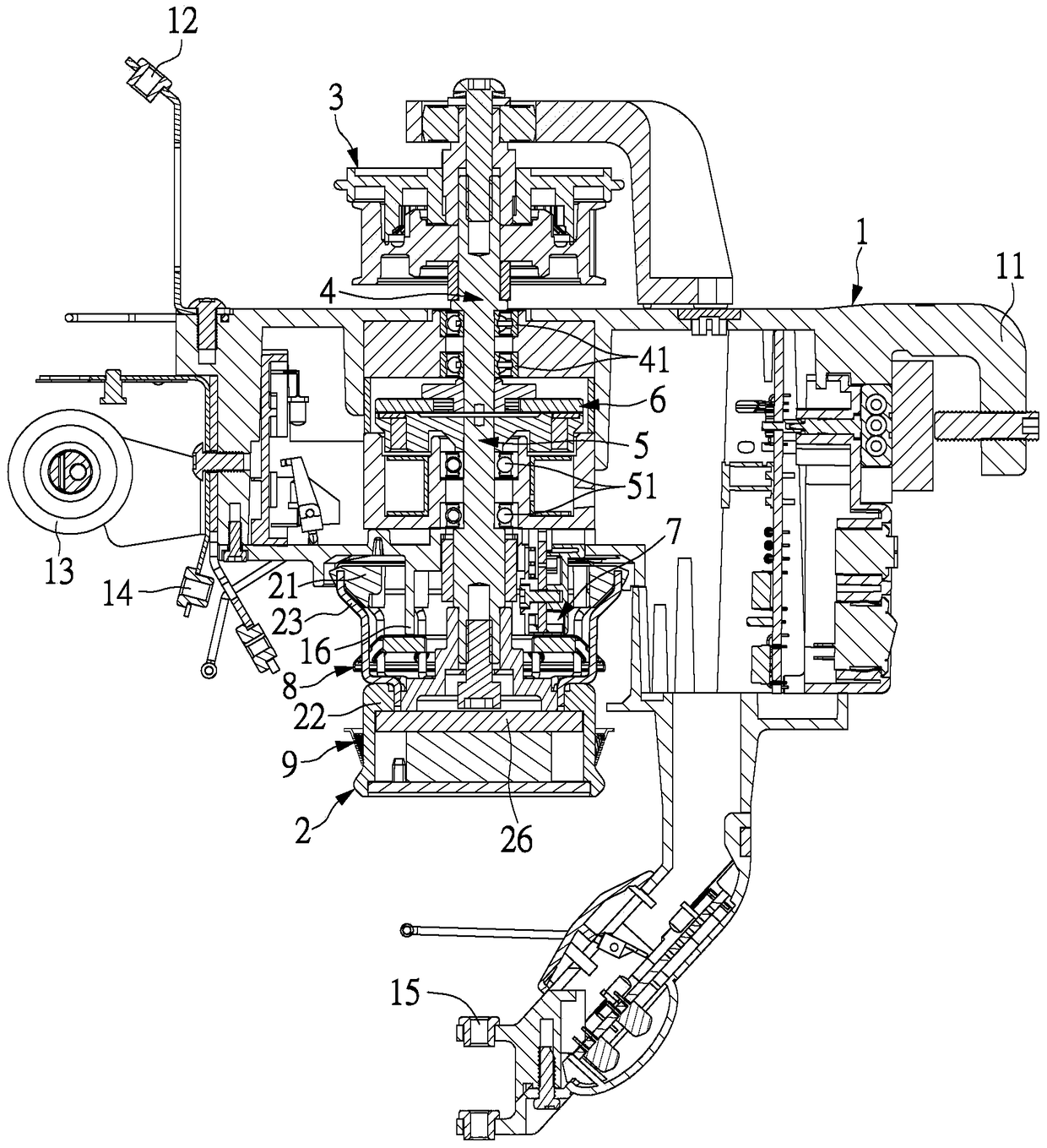

[0069] see figure 2 , The electromagnetic clutch type yarn feeding device of this embodiment includes a body 1 , a yarn storage w...

no. 2 example

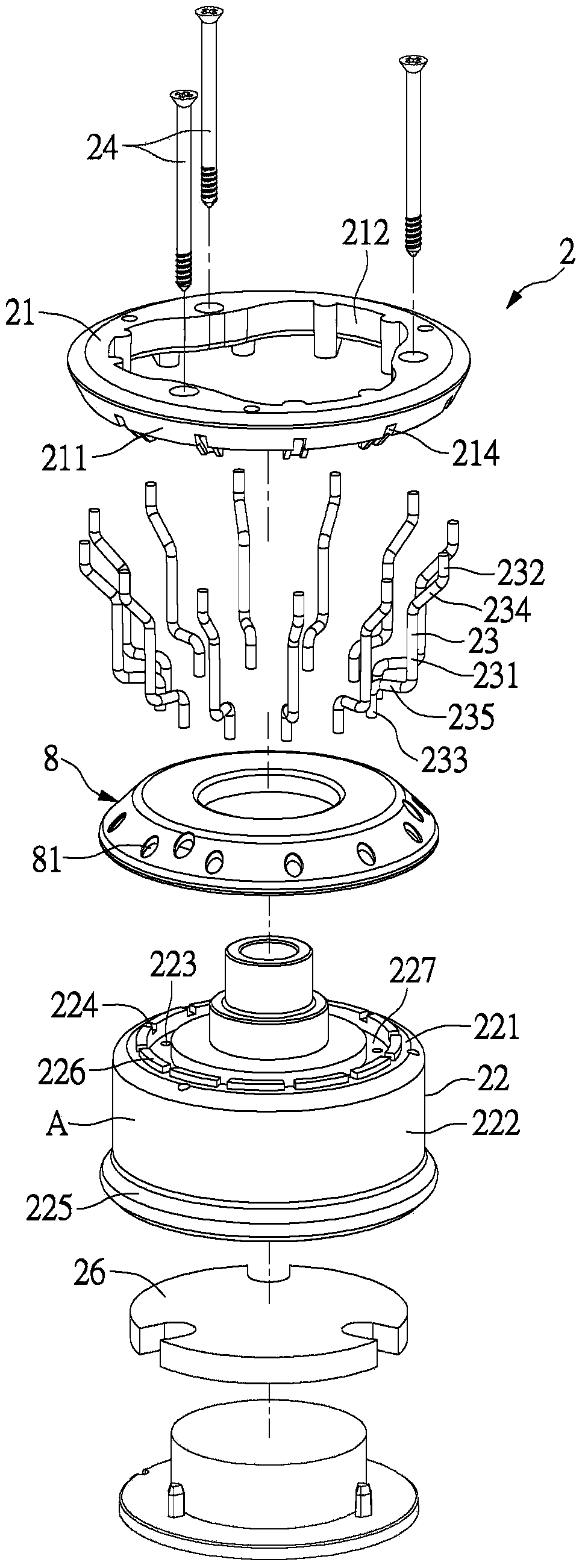

[0086] see Figure 3 to Figure 6 , the present invention additionally provides a method for assembling the yarn storage wheel of the yarn feeding device, comprising the following steps:

[0087] First, an upper wheel body 21, a lower wheel body 22, a plurality of yarn storage nails 23 and a floating disc 8 are provided; the structures of the upper wheel body 21, the lower wheel body 22, the yarn storage nails 23 and the floating disc 8 have been Described in the above-mentioned embodiment, so repeat it no longer;

[0088] Then, the floating disc 8 is placed on the top plate 221 of the lower wheel body 22, so that the perforations 81 correspond to the second insertion holes 223;

[0089] Next, insert the lower end portions 233 of the yarn storage nails 23 into the corresponding second insertion holes 223 of the lower wheel body 22 through the corresponding through holes 81; and

[0090] Then insert the upper ends 232 of these yarn storage nails 23 into the corresponding first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com