Preinstallation of a pressure sensor module

A pressure sensor and isolator technology, applied in the direction of measuring fluid pressure, measuring fluid pressure through electromagnetic components, instruments, etc., can solve problems such as damage and pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

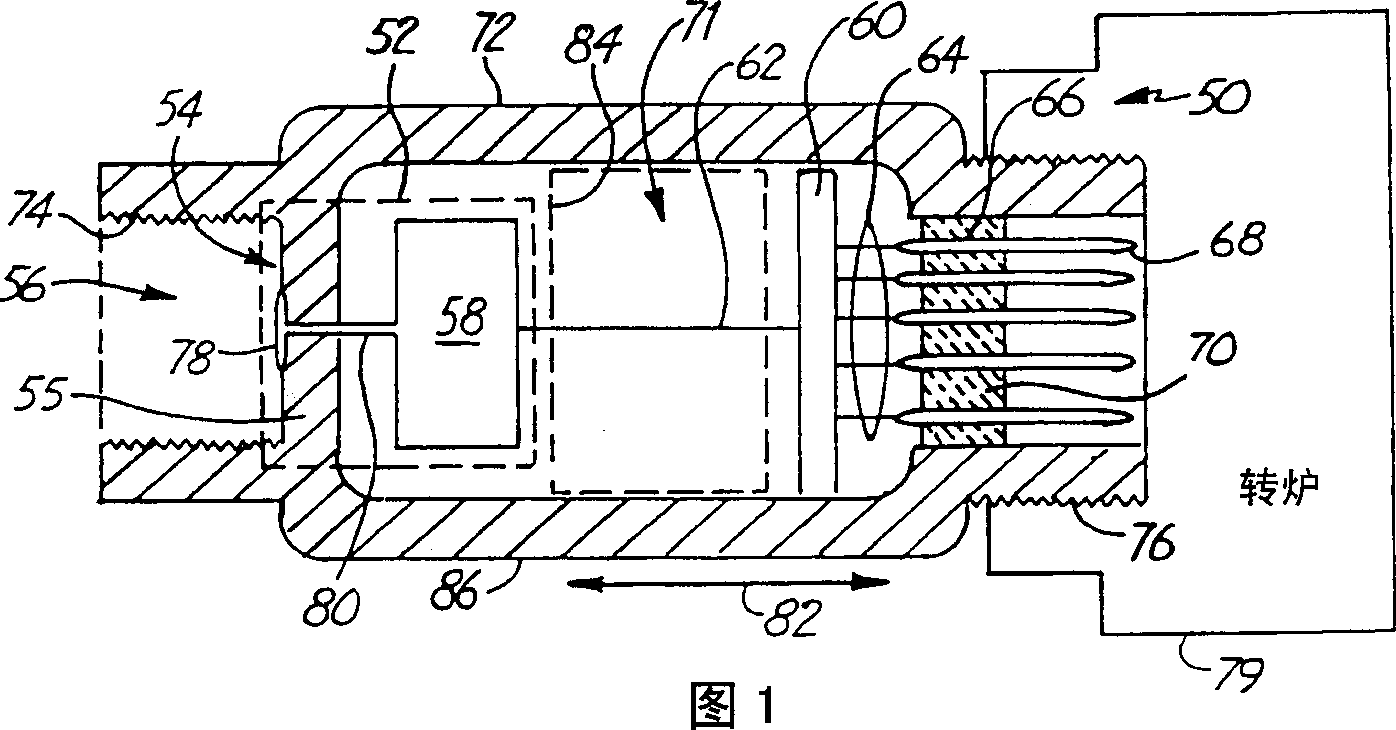

[0020] As shown in FIG. 1, the improved pressure sensor module housing has an integrally formed threaded process fluid inlet and an integrally formed threaded boss or support housing for supporting the wiring structure. The bushing also provides support for the converter module. In the pressure sensor module, the casing seals the sensor and electronic components, so that it can be installed independently on site without installing the converter module first, and it can ensure that the electronic components of the pressure sensor are not exposed to harsh on-site air. middle. Process fluid piping can be connected and pressure tested with the modified pressure sensor module at an early stage of process system construction even when the transducer module does not yet exist. In process system construction, the improved pressure sensor module can be stored outdoors or in the field environment for an extended period of time without damage to the sensor or the electronic components i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com