Fluid bed apparatus module and method of changing a first module for a second module in a fluid bed apparatus

A fluidized bed and fluidized gas technology, applied in chemical instruments and methods, hearth furnaces, chemical/physical processes, etc., can solve problems such as labor-intensive and troublesome operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

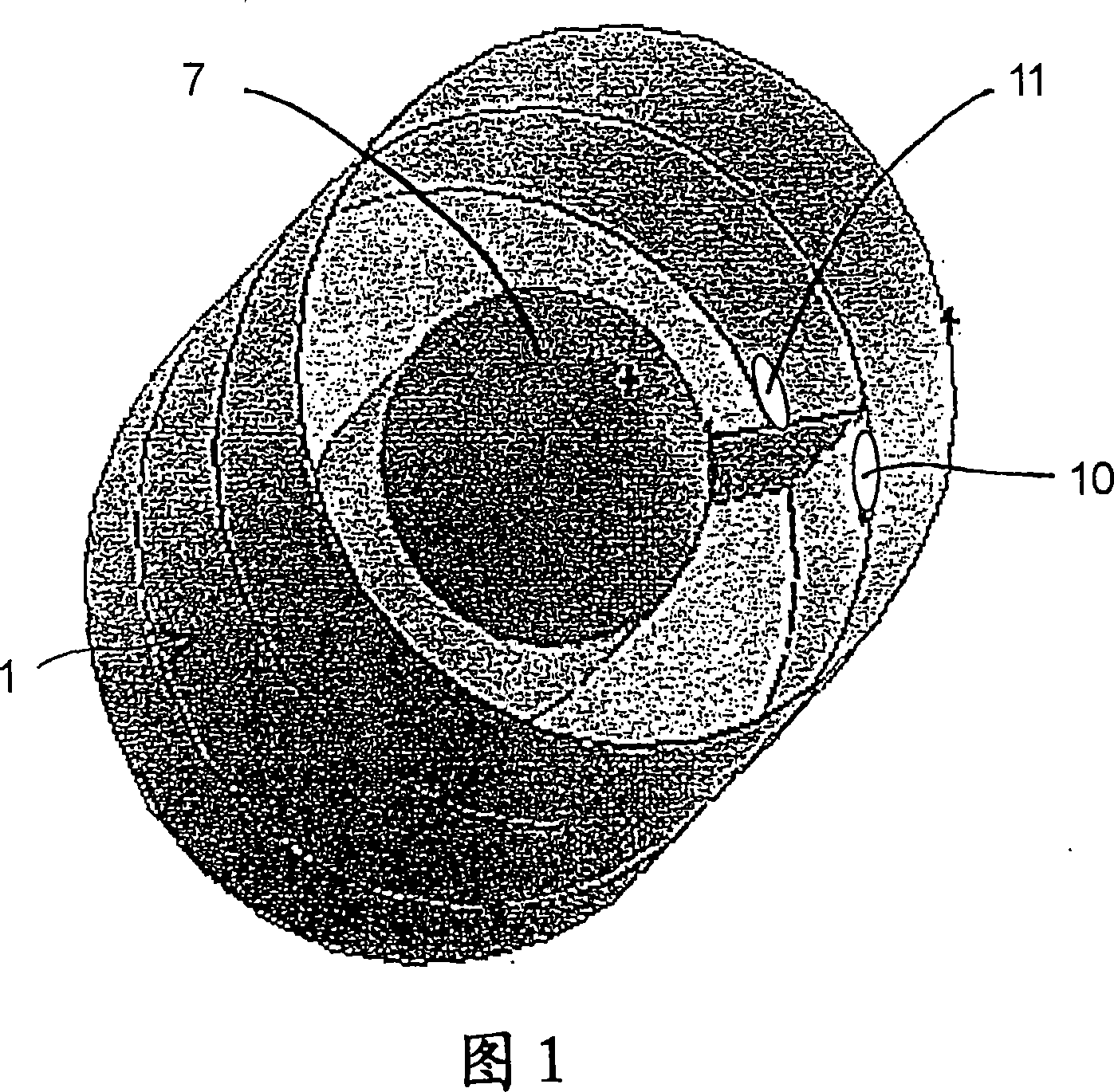

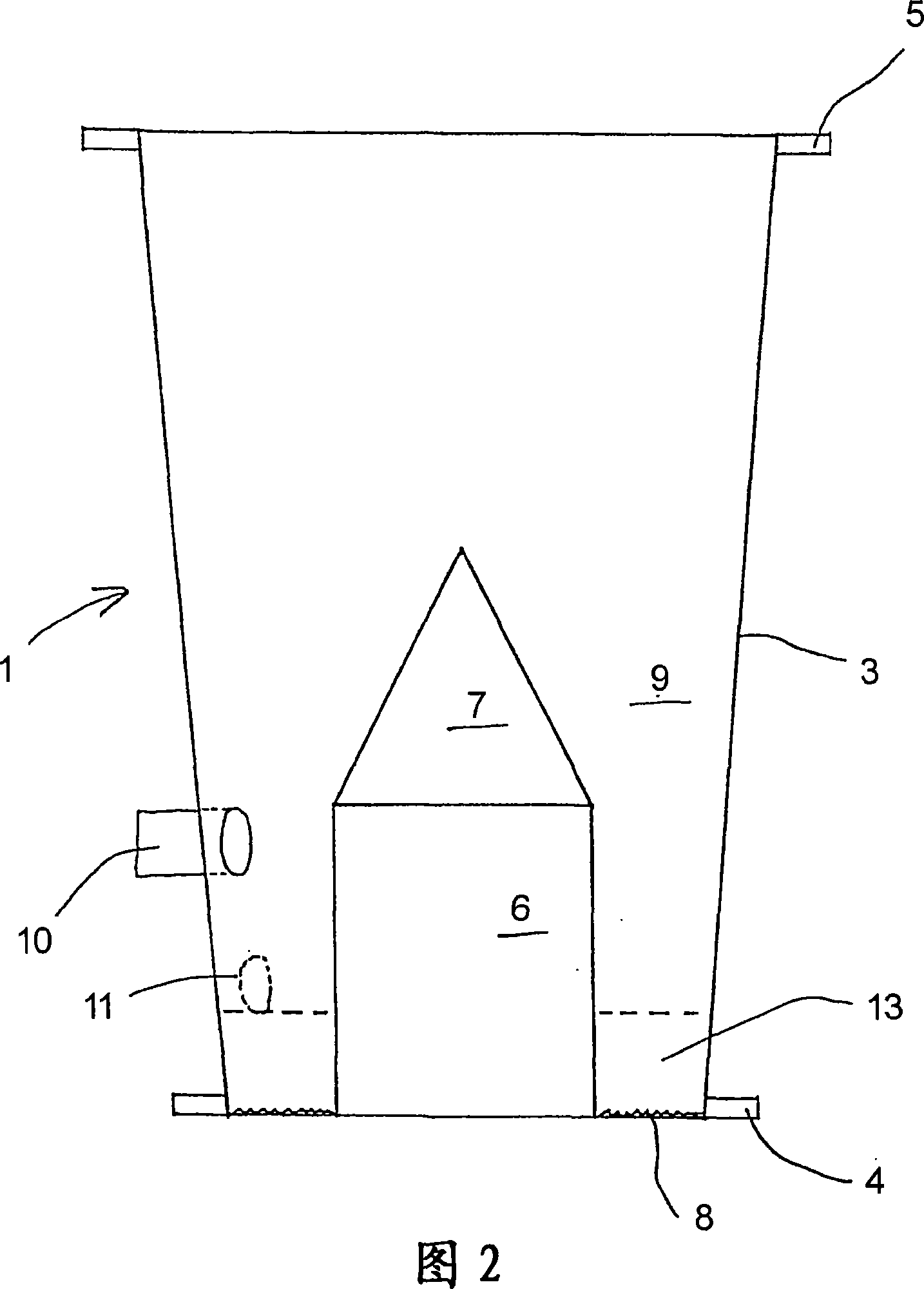

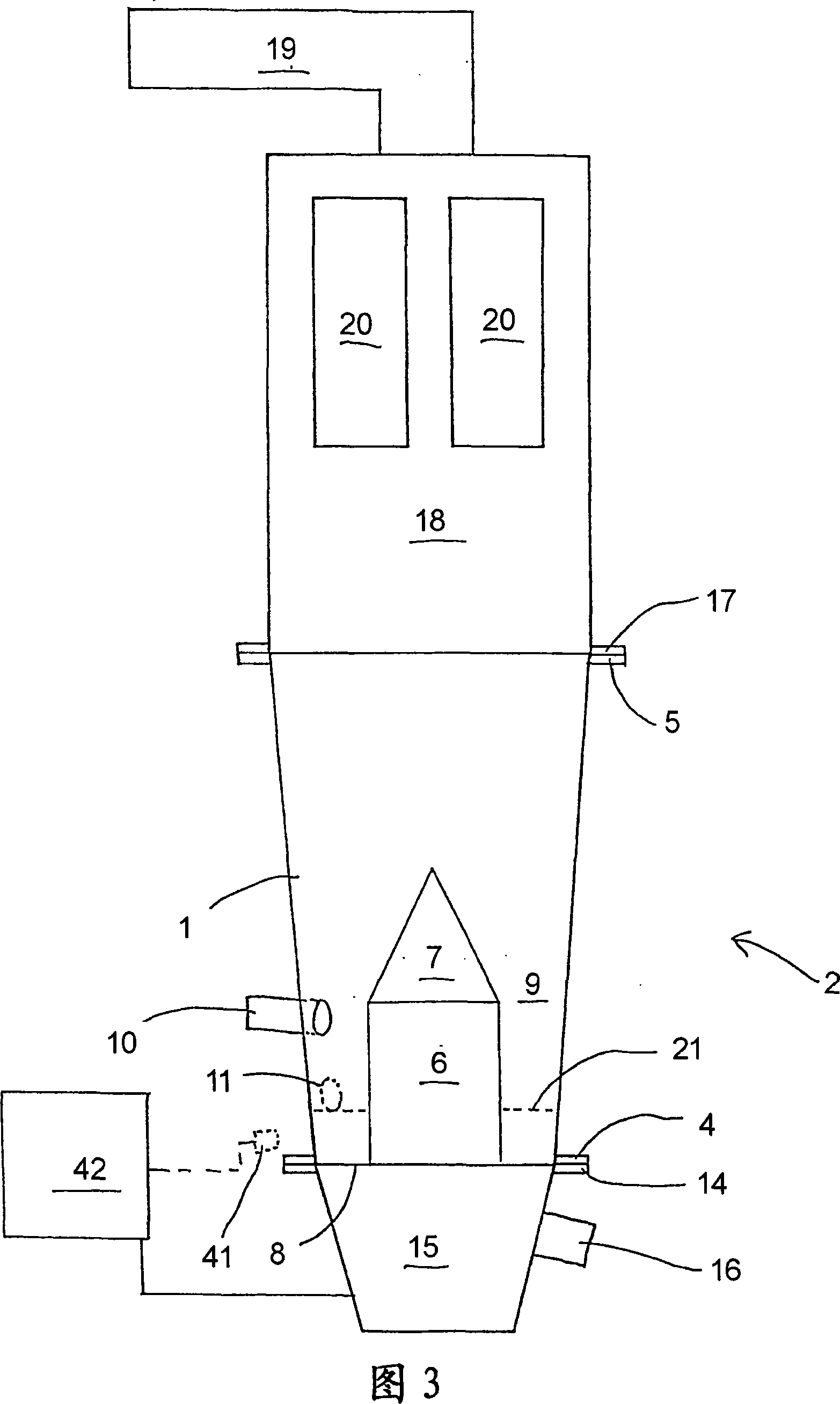

[0035] 1 and 2 show a fluidized bed plant module 1 for a fluidized bed plant as shown in FIG. 3 . The fluidized bed device 2 according to the invention can be used, for example, for drying partially dried but still moist powdered or granular products such as pharmaceuticals or nutraceuticals. The moist product to be dried in the fluidized bed device may have been produced, for example, in a spray drying process or in an extrusion process. In addition to drying, the unit is also suitable for granulation, agglomeration or coating. Although the device according to the invention is particularly suitable for the mentioned processes within the pharmaceutical industry, the invention can generally also be applied to other products and fluidized bed reactors.

[0036] The fluidized bed plant module 1 shown in FIG. 2 comprises a conical outer wall 3 with a lower flange connection 4 and an upper flange connection 5 . A cylindrical core 6 is arranged concentrically with this outer wall ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com