Method for processing sludge from papermaking and pulping by using earthworms, method for separating sludge and earthworms

A sludge and earthworm technology, which is applied in biological sludge treatment, sewage/sludge fertilizer, application, etc., can solve the problems of papermaking pulping sludge without earthworms, large amount of biochemical sludge, and low degree of resource utilization , to achieve the effect of saving pesticides and fertilizers, low cost, and uniform particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

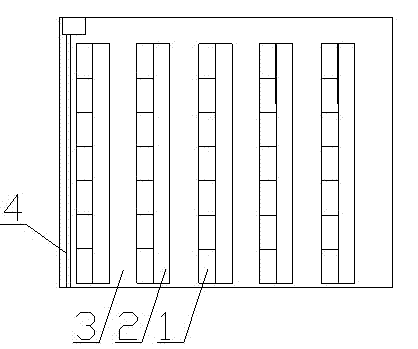

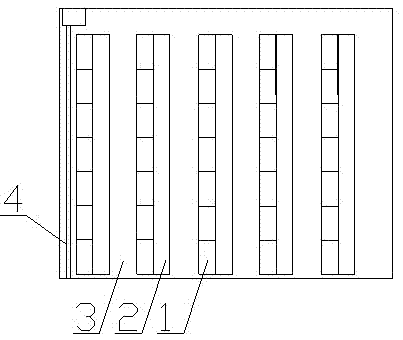

[0022] Embodiments of the present invention: as figure 1 As shown, the sludge storage yard 3 is built. The size of the sludge storage yard 3 is based on the sludge volume of the paper mill. The sludge storage volume is 2 to 3 days. Slope angle, or the storage yard with high middle and low sides, build sewage collection ditch 4 on the inclined slope side. The slope angle of the storage yard is generally 2-3 degrees. After the sludge storage yard is built, the papermaking and pulping The sludge is poured into the sludge storage yard 3. It is recommended that the sludge stored in the sludge storage yard be treated as a sludge treatment bed within 24 hours. The height, length and width of the sludge treatment bed are based on the length of the sludge storage yard. It depends on the width; it is generally preferred that the width of the sludge treatment bed is 1.0-1.5 meters, the length is 10-15 meters, and the height is 0.4-0.5 meters. The interval between the two treatment beds i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com