Efficient metallurgical rotary kiln for treating lead-zinc oxide ore

A lead-zinc oxide, rotary kiln technology, applied in rotary drum furnaces, furnaces, furnace types, etc., can solve the problem of not being able to obtain effective volatilization recovery, and achieve the effect of reducing material kiln formation and prolonging production cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

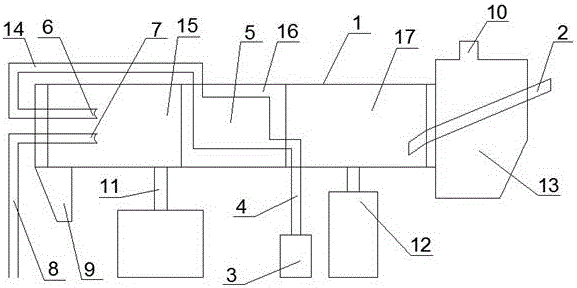

[0021] After mixing and granulating lead and zinc oxide mineral materials with coke powder and raw coal at a ratio of 1:0.30 to 0.35, they are fed into the preheating zone 17 of the rotary kiln body 1 through the feed port 2, and the Driven by the body mechanical transmission assembly 12, during the rotation of the rotary kiln body 1, the coke powder and raw coal in the material are continuously ignited and burned in the preheating zone 17, so that the temperature of the material rises to between 680-700 °C. The rotary kiln body 1 gradually transports the material to the high temperature zone through rotation, so the material is continuously sent to the reduction zone 16 as the rotary kiln body 1 rotates. The heat exchanger 5 uses the heat produced by the rotary kiln itself to heat the high-pressure air generated by the blower device 3 into hot air with a temperature of about 500°C, and then feeds it from the hot air inlet 6 to the reduction zone 16 of the rotary kiln through t...

Embodiment 2

[0023] On the basis of Example 1, if the hot blast heated by the heat exchanger 5 is added to the reduction zone 16 of the rotary kiln body 1 through the hot blast pipe 14 from the hot blast inlet 6, the temperature of the reduction zone 16 cannot reach the required level. 1200-1300°C, the gas nozzle 7 can be opened, and coal gas or natural gas can be sprayed into the reduction zone 16 to ensure that the temperature of the rotary kiln is between 1200-1300°C, so as to ensure that the lead, zinc and other metals in the material are in the rotary kiln body The reduction zone 16 of 1 is reduced, volatilized and oxidized to form metal oxides.

[0024] The feature that the present invention differs from the traditional rotary kiln is:

[0025] 1) A heat exchanger is added outside the reduction zone of the rotary kiln body. The heat exchanger heats the air produced by the blower equipment to about 500 degrees, and blows it in from the hot air heating port at the head of the rotary ki...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com