Technology of Direct Reduction of Ferronickel Particles of Laterite Nickel Ore in Rotary Kiln

A laterite nickel ore and rotary kiln technology, applied in the field of metallurgical technology, can solve the problems of shortening the life of refractory kiln lining, poor operability, and high requirements for refractory materials, so as to facilitate reduction and enrichment, slow down the travel speed, and improve reduction efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A kind of technology that rotary kiln directly reduces laterite nickel ore ferronickel particle, it comprises the following steps:

[0022] 1) Batching and pelletizing: After mixing the dried and crushed laterite nickel ore with carbonaceous reducing agent, limestone and binder, the balls are pressed on a briquetting machine to form mixed pellets. The laterite nickel ore, carbonaceous The dosage ratio of reducing agent, limestone and binder is 84.5:13:2:0.5;

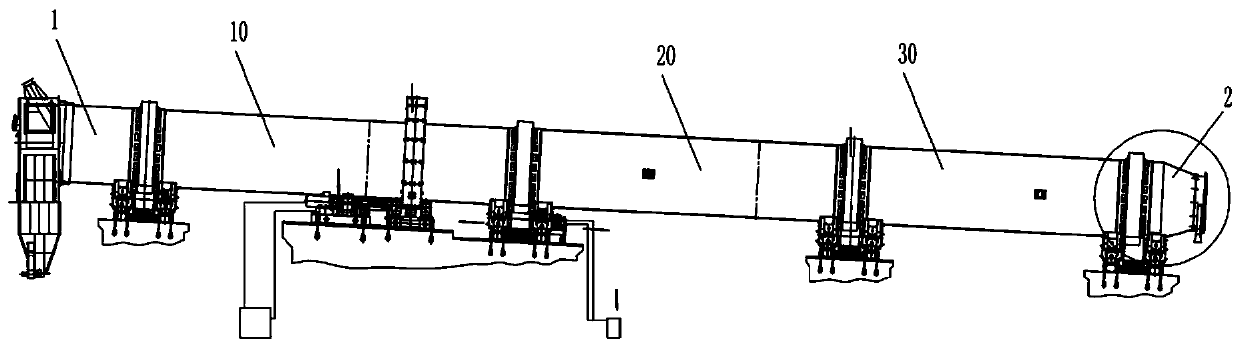

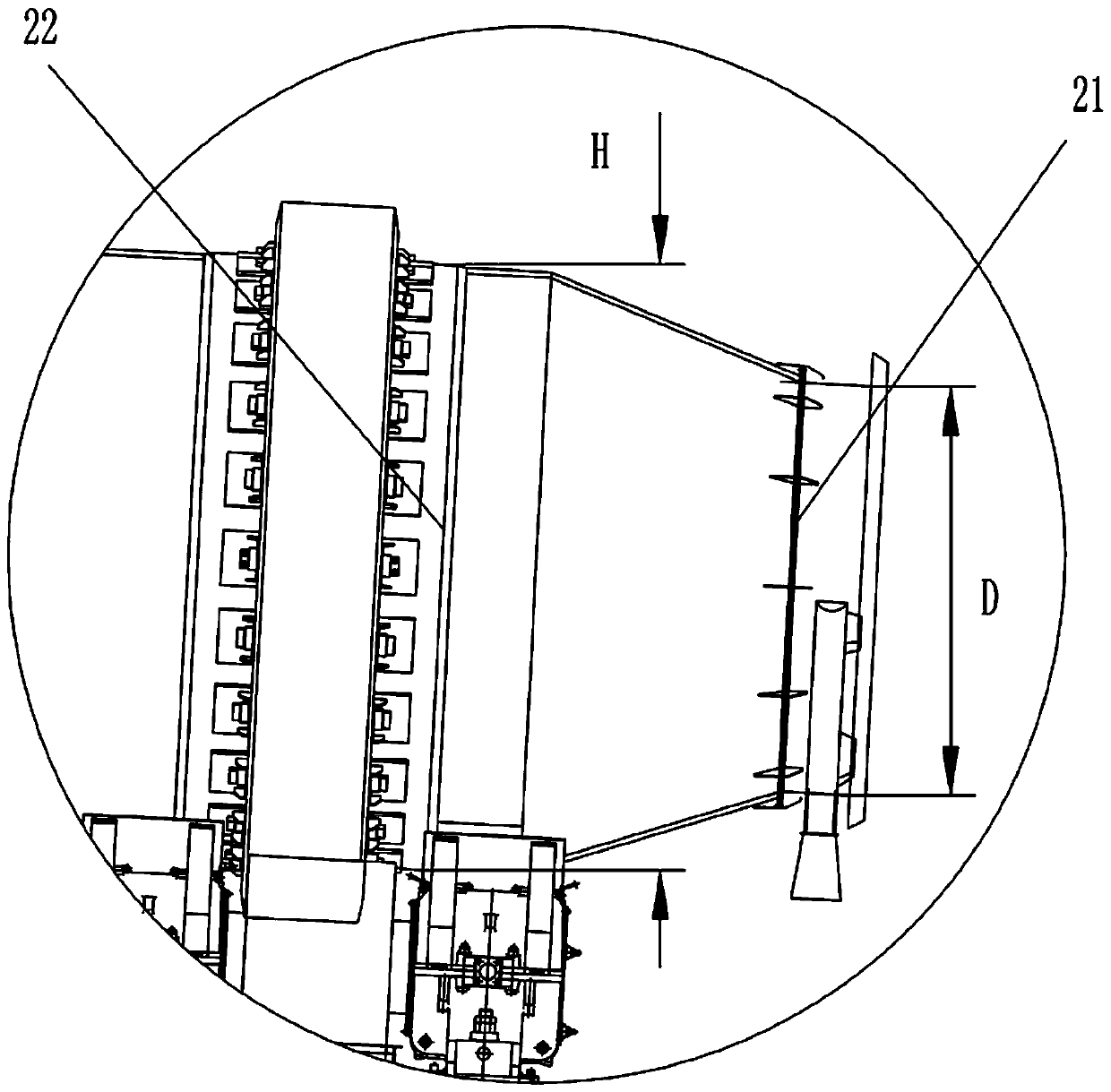

[0023] 2) Reduction roasting: Send the mixed pellets into the rotary kiln for roasting, such as figure 1 and figure 2 As shown, the rotary kiln is provided with a preheating section 10, a transition section 20 and a firing section 30 from the kiln tail 1 to the kiln mouth 2. The kiln mouth 2 of the rotary kiln is a necking structure, and the necking section The length of the rotary kiln is 5m, the temperature of the preheating section in the rotary kiln is 400-650°C, the temperature of the transition section is...

Embodiment 2-7

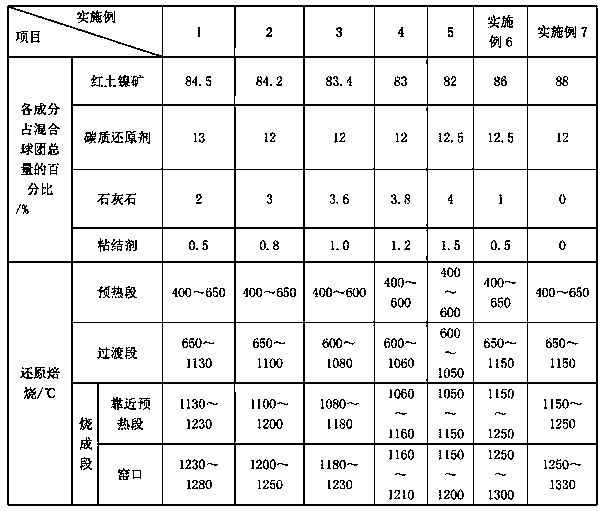

[0027] Examples 2-7 take the same steps as in Example 1, the difference lies in the proportion of raw materials used in step 1) in the mixed pellets, and the temperature of each stage in the reduction roasting process is different. The specific data are shown in Table 1:

[0028] Table 1

[0029]

[0030] The water quenching and beneficiation steps of the present invention are prior art, the binder is a commercially available product, and its composition will not be described in detail here; the carbonaceous reducing agent is any one of coke powder, anthracite or semi-coke; like figure 1 and figure 2 As shown, the rotary kiln of the present invention includes a kiln tail 1 and a kiln mouth 2, and the kiln mouth 2 is a necking structure, wherein, the length of the necking in Example 1 is 5m, and the diameter D of the front end 21 of the necking is 3.44 m, the diameter H of the necking rear end 22 is 4.85m; the length of the firing section is 30m, in actual production, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com