Testing apparatus for research on reducibility of single-particle iron ore

A test device and iron ore technology, which is applied in the field of ironmaking in the metallurgical industry, can solve problems affecting the reliability of sample quality changes, uneven heating of samples, and inconsistent reduction degrees of samples, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

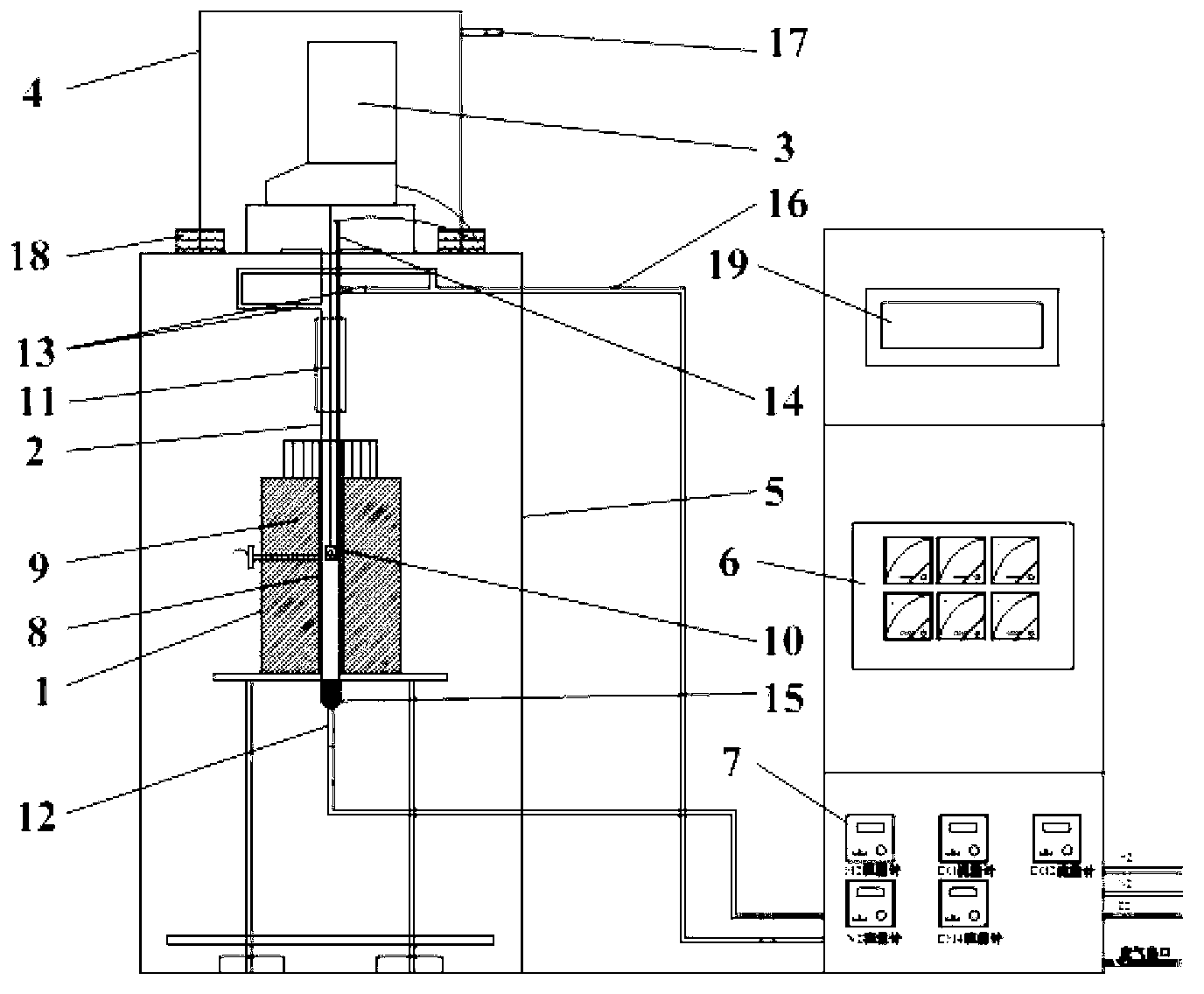

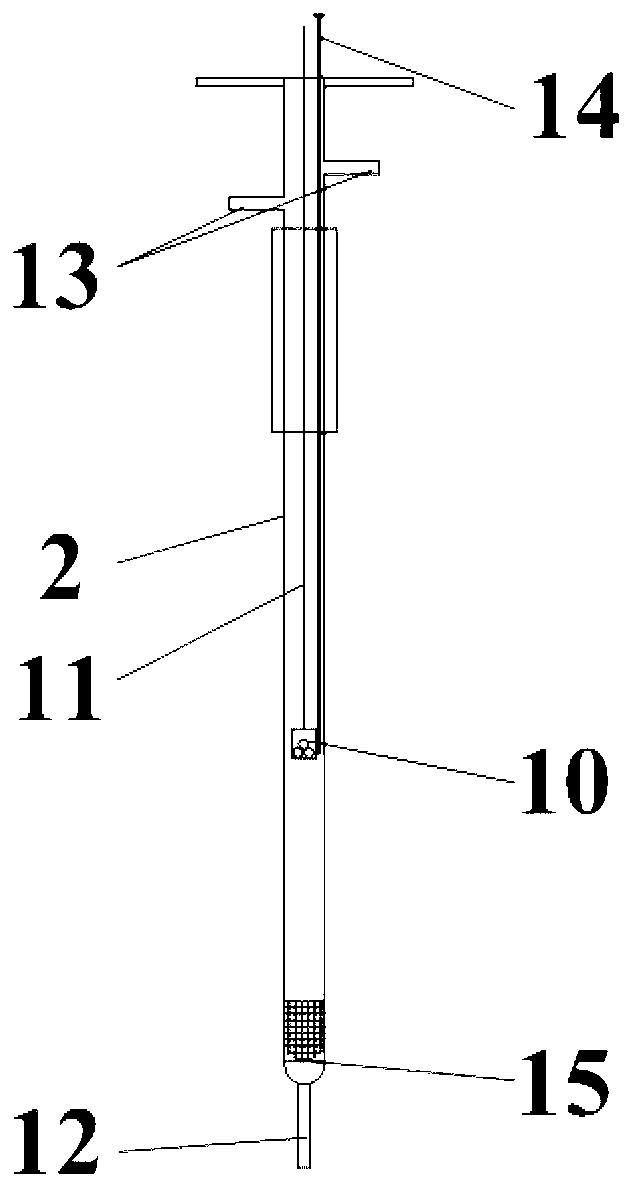

[0021] Such as figure 1 As shown, the present invention is a test device for studying the reducibility of single particle iron ore, which includes a reduction furnace 1 and a quartz reduction tube 2. The reduction furnace 1 includes a furnace chamber 8 and a heating device 9, and the quartz reduction tube 2 passes through a support device 5 Fixed in the furnace cavity 8, the quartz reduction tube 2 is provided with a thermocouple 14 and a porous plate 15, and the quartz reduction tube 2 is also provided with a reducing gas inlet 12 and two reducing gas outlets 13. During the test, at first the single particle iron ore sample is placed in the hanging basket 10 and then suspended below the weighing device 3 by the hanging wire 11 . Then the protective device 4 is connected with the water seal tank 18, and the protective gas is introduced through the protective gas inlet 17 and the reducing gas inlet 12 to remove the oxidizing air in the protective device 4 and the quartz reducin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com