Method for inhibiting hydrocracking temperature runaway by using reaction pressure

A technology of reaction pressure and hydrocracking, which is applied in the fields of hydrocarbon oil cracking and petroleum industry, can solve the problem of reaction pressure drop and achieve the effect of suppressing and avoiding overheating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

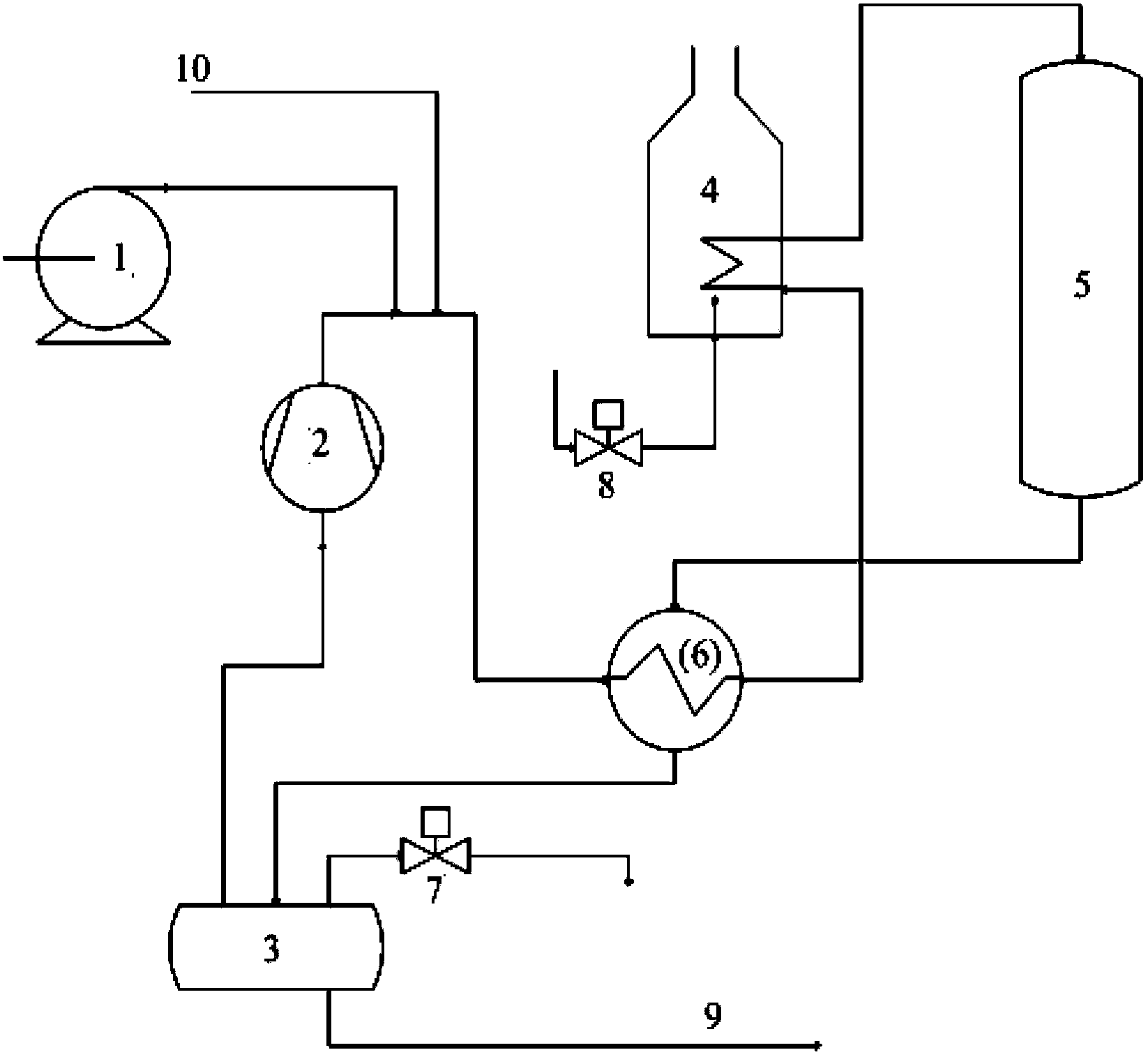

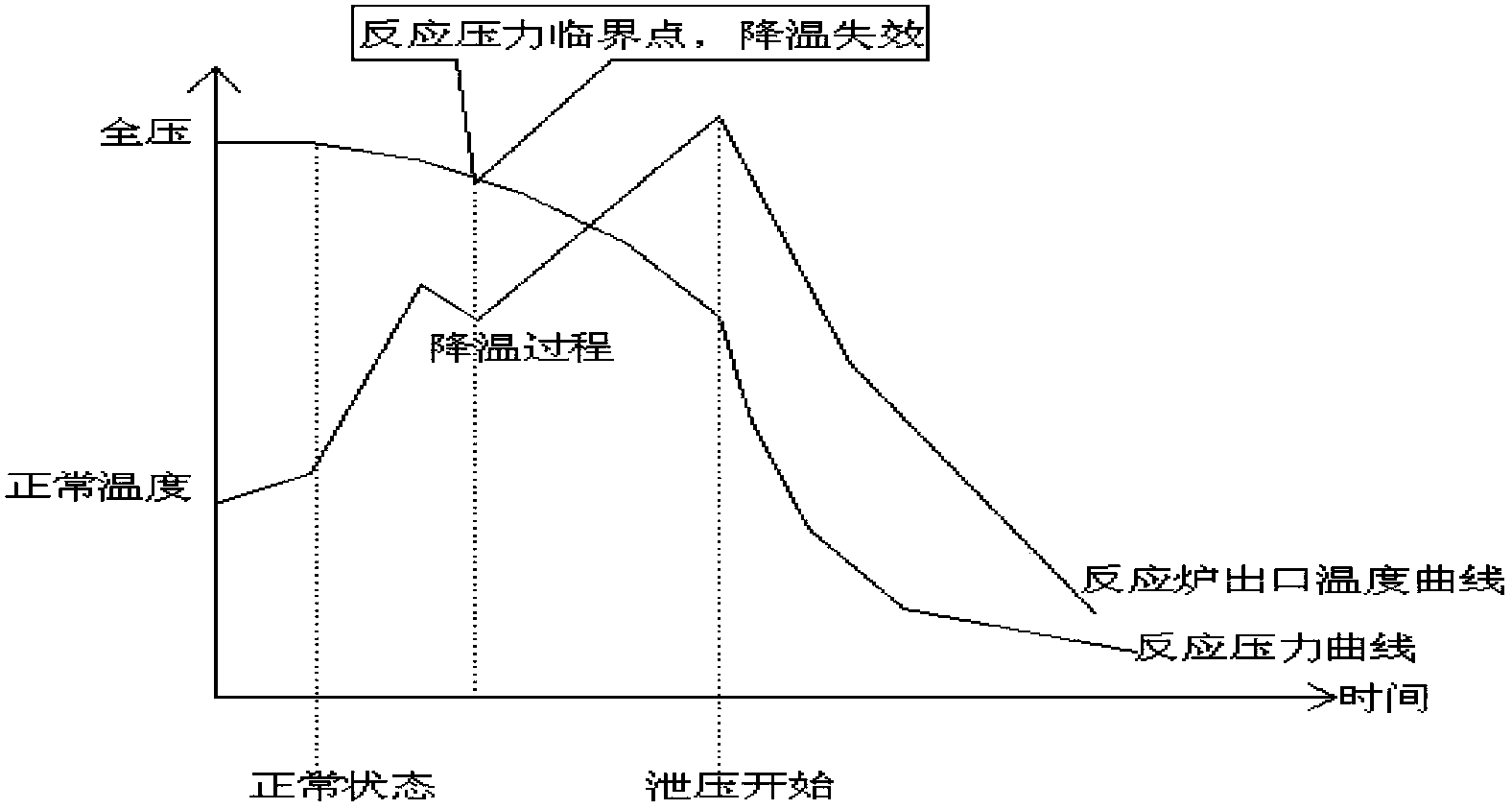

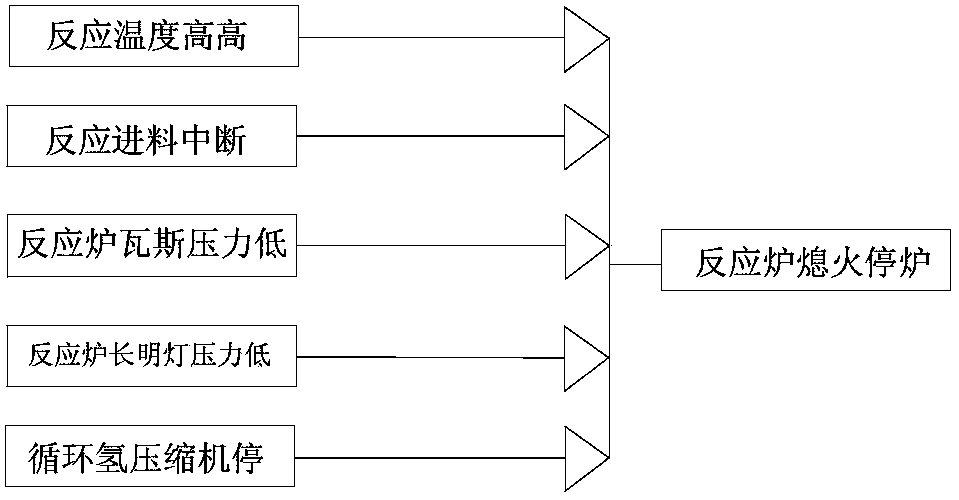

Method used

Image

Examples

Embodiment 1

[0026] In a CNPC hydrocracking unit referred to in this example, the cracking catalyst is mainly an amorphous type that is not easy to overheat, mixed with a small amount of molecular sieve, and the critical point of reaction pressure is 80.16% of the total reaction pressure, that is, the normal reaction pressure is 14.5Mpa. The reaction pressure critical point is 11.623Mpa.

Embodiment 2

[0028] The reaction pressure of a hydrocracking unit is 15.7Mpa, and the critical point of the reaction pressure is 80.16% of the total reaction pressure, so the critical point should be 12.585Mpa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com