Block type end plate structure for measuring current distribution of PEMFC

A proton exchange membrane, fuel cell technology, applied in solid electrolyte fuel cells, fuel cells, fuel cell additives, etc. problems such as poor field similarity, to achieve the effect of improving the structure of the battery pack, significant economic benefits, and a simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

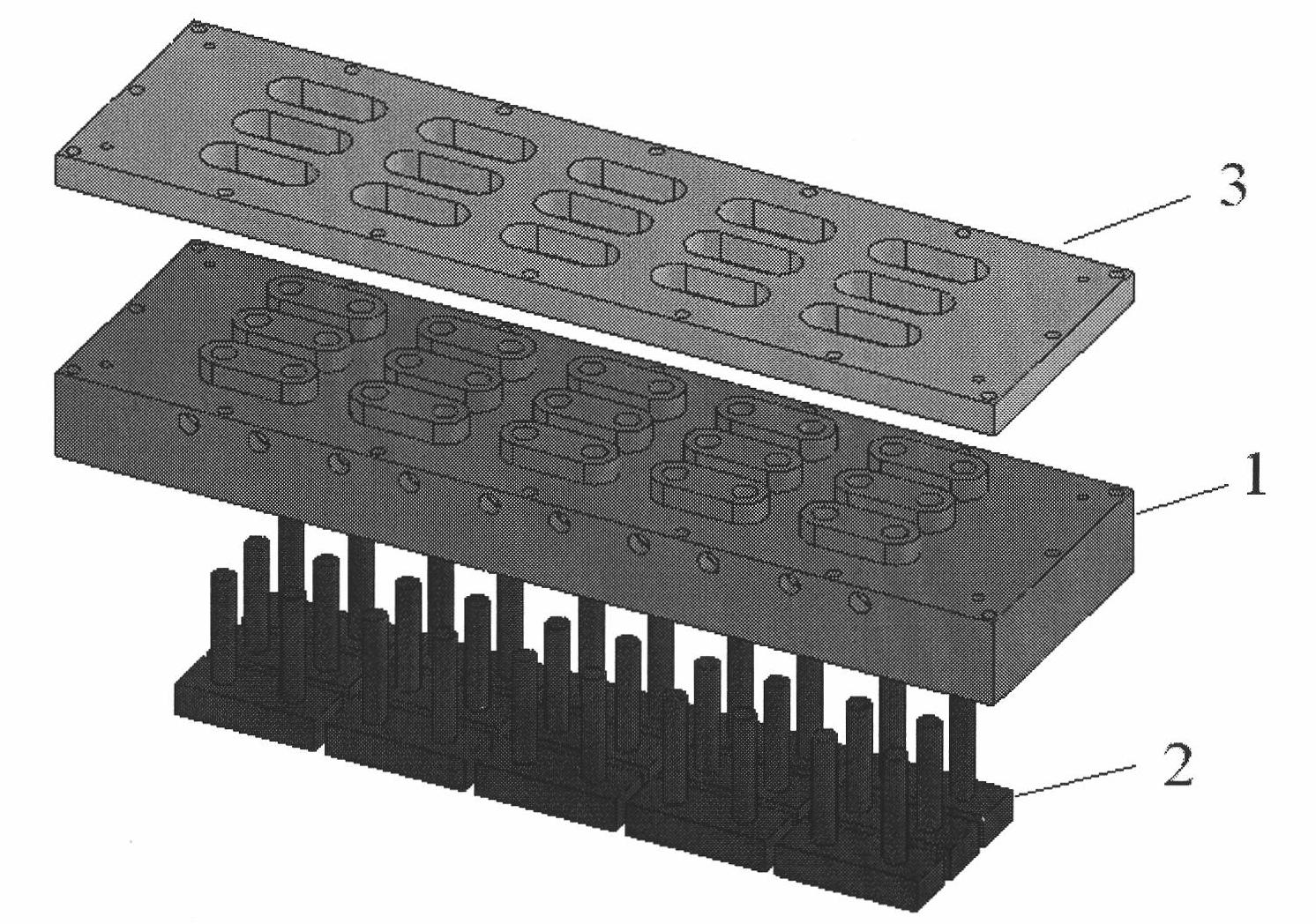

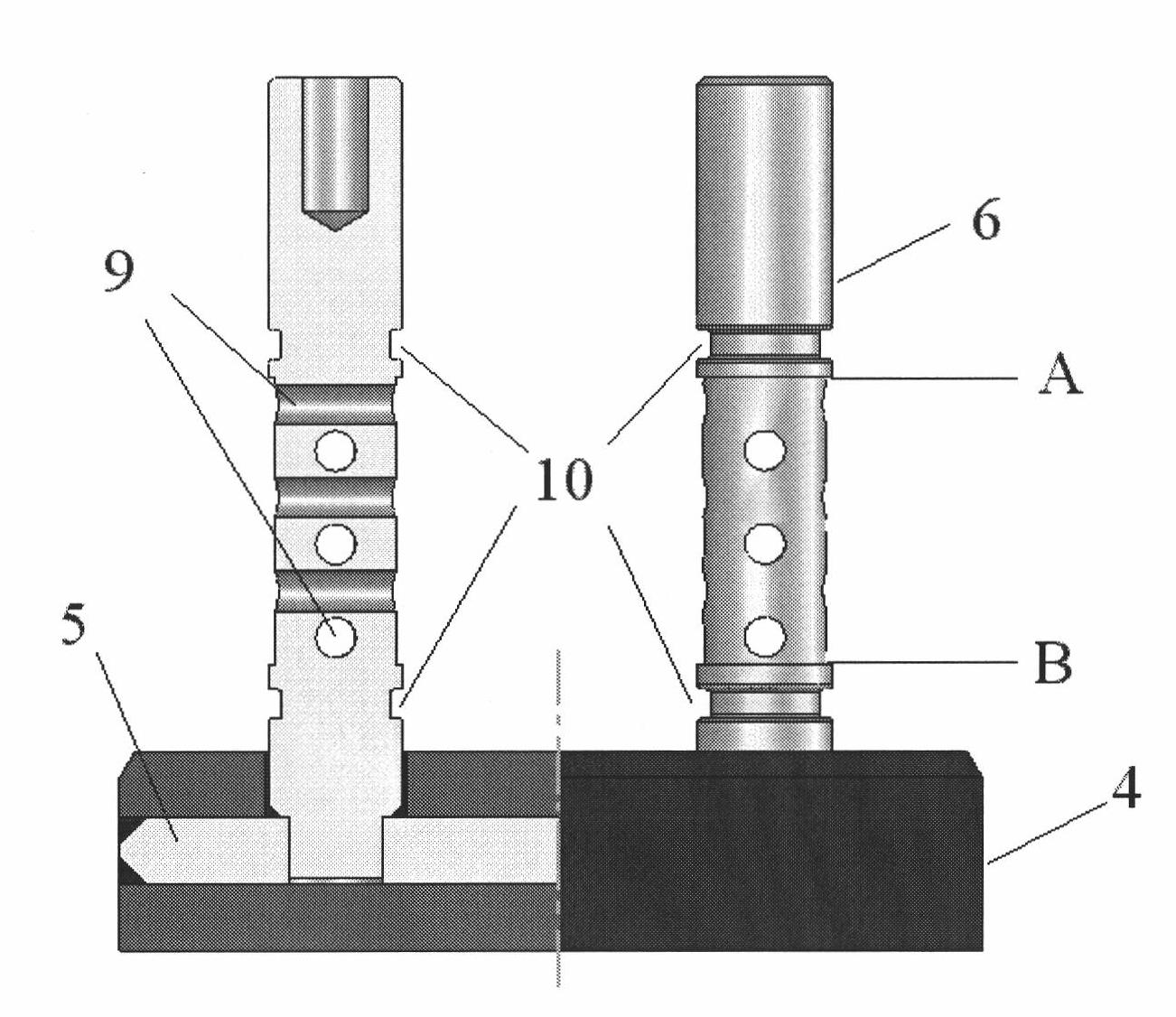

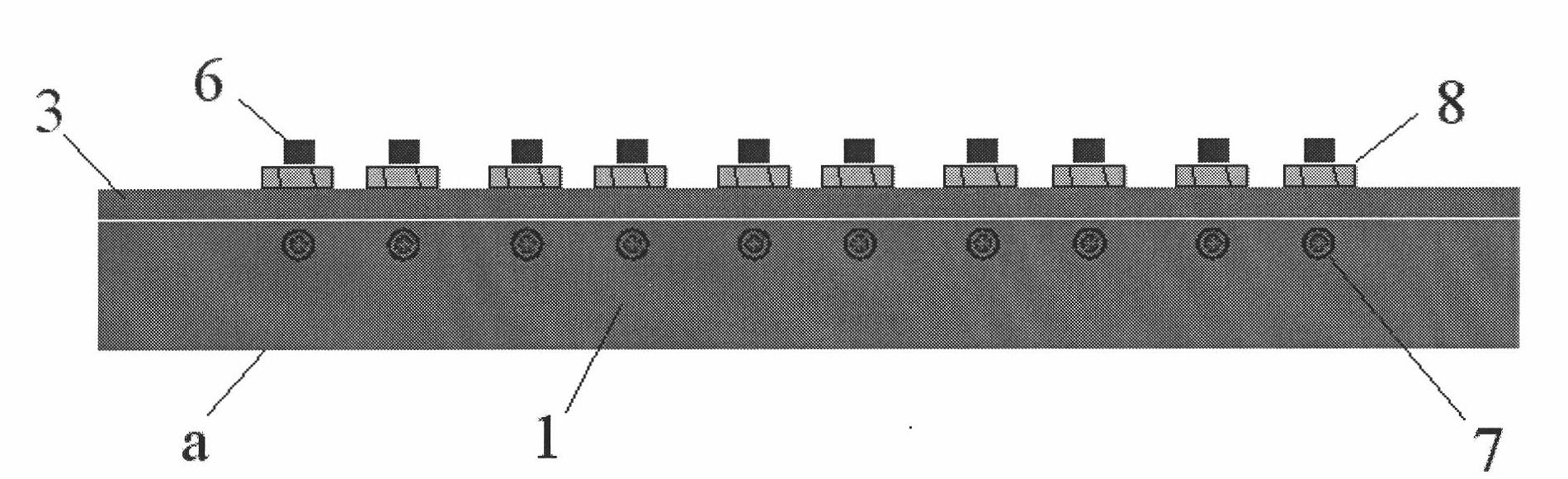

[0032] The main body of the end plate of the present invention is composed of an insulating mother board, a sub-collector block and a reinforced back plate. In this method, a plurality of sub-collector blocks are embedded in the insulating mother board, and the surface of the insulating mother board embedded in the sub-collector blocks is milled and carved normally. The reactive air flow field is embedded in the back to increase the overall strength of the end plate. By controlling the circulating water temperature, the temperature of the end plate as a whole, especially the temperature of each sub-collector block, can be flexibly adjusted. The end plate with sub-collector blocks is used to assemble the battery. Use wires to separately collect current from the sub-collector block to achieve the purpose of testing current distribution. The invention can visually observe the distribution and change of the internal current of the battery, effectively know the internal reaction of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com