Method for manufacturing pipeline through reaction injection-rotation moulding, pipeline die and pipeline moulding device

A rotational molding and injection molding technology, which is applied in applications, household appliances, tubular objects, etc., can solve the problems of polymer material pipes that are hard to come out, and achieve the effect of easy quality control, easy demoulding, and smooth outer wall

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

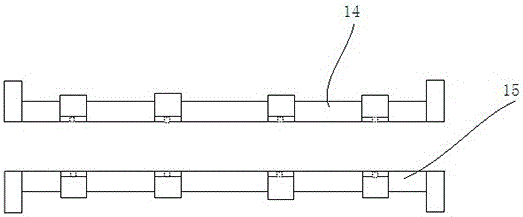

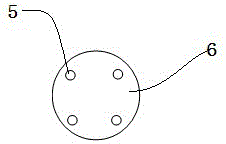

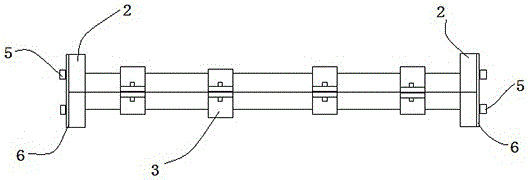

[0029] Embodiments of the pipe forming apparatus of the present invention, such as Figure 1 to Figure 4 As shown, the pipeline mold is comprised, and the pipeline mold comprises a mold body 1, and the mold body 1 comprises an upper mold 14 and a lower mold 15, and the upper mold and the lower mold are all provided with arc-shaped inner concave surfaces. The arc-shaped inner concave surface is combined to form a cylindrical mold cavity. Flanges 2 are provided at the front and rear ends of the mold body 1, and the flanges are connected to the corresponding flange covers 6 and realized circular through flange cover fixing screws 5. The two ends of the cylindrical mold cavity are sealed, and an injection port (not shown in the figure) is opened at the center of one of the flange covers; four fastening sleeves are set at intervals along the axial d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com