Method for preparing rare earth doped aluminum nitride based blue fluorescent powder

A rare earth doping, aluminum nitride technology, applied in chemical instruments and methods, luminescent materials, etc., can solve the problems of high preparation cost, low production efficiency, limited application scope, etc., and achieve short preparation time, low cost, and improved efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

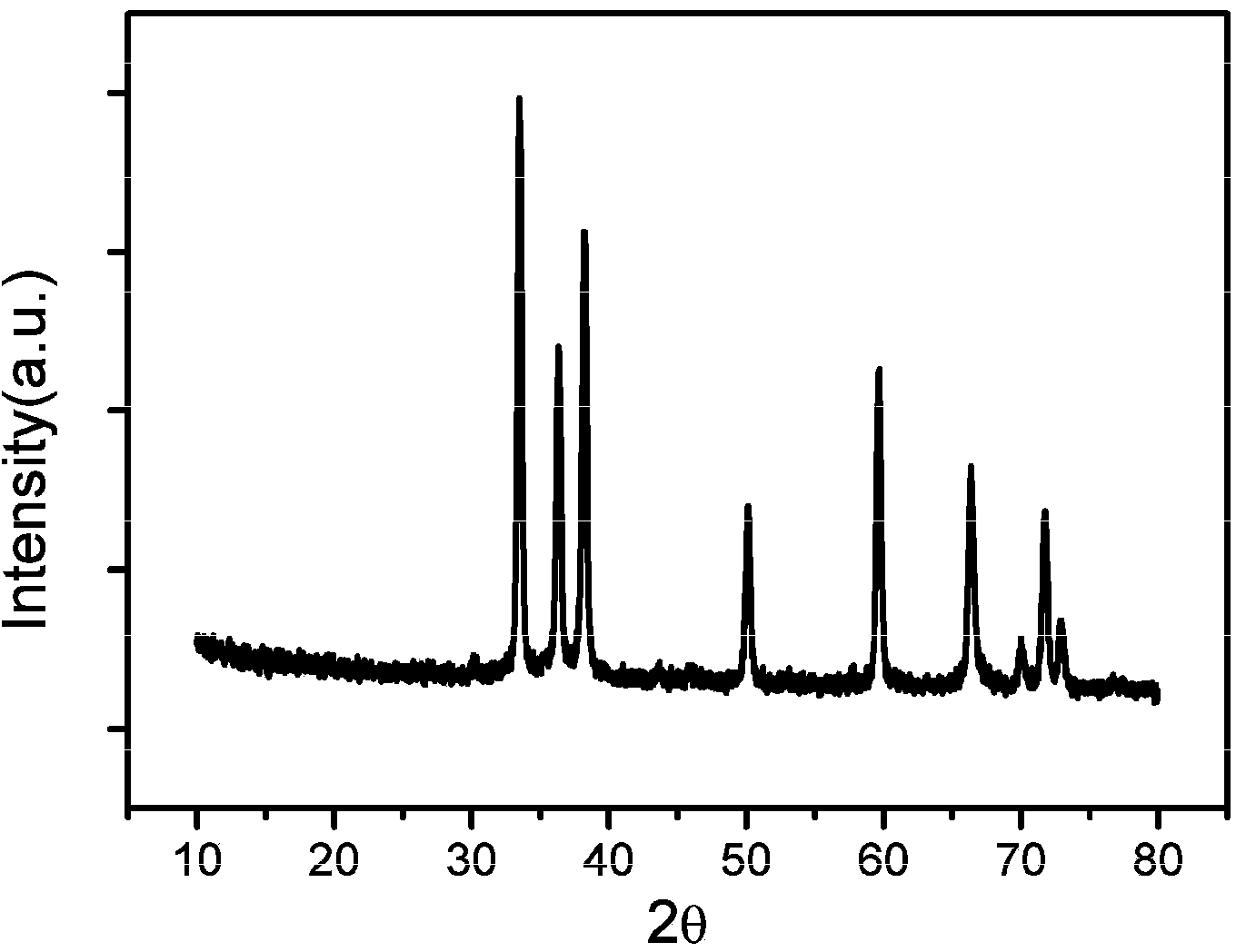

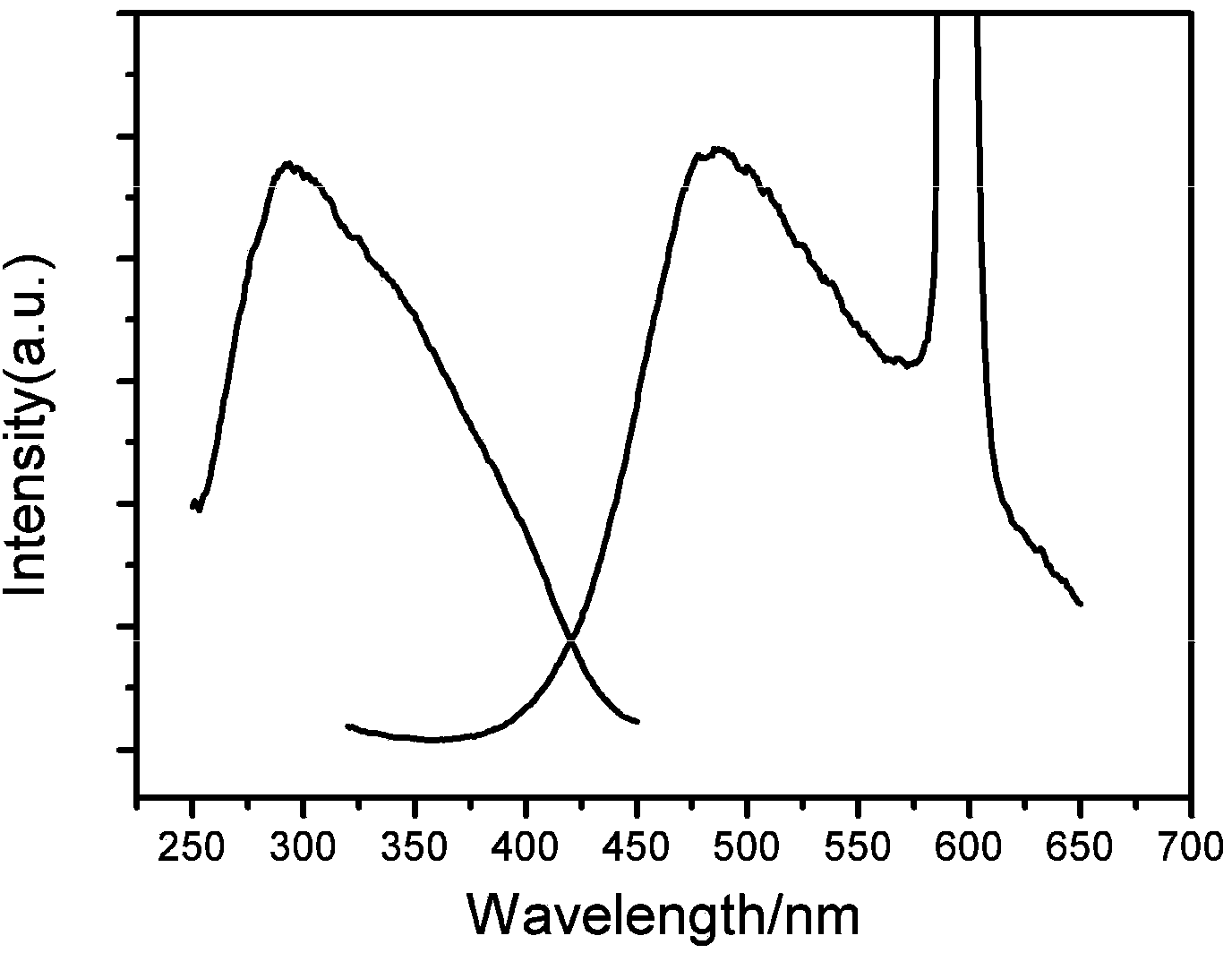

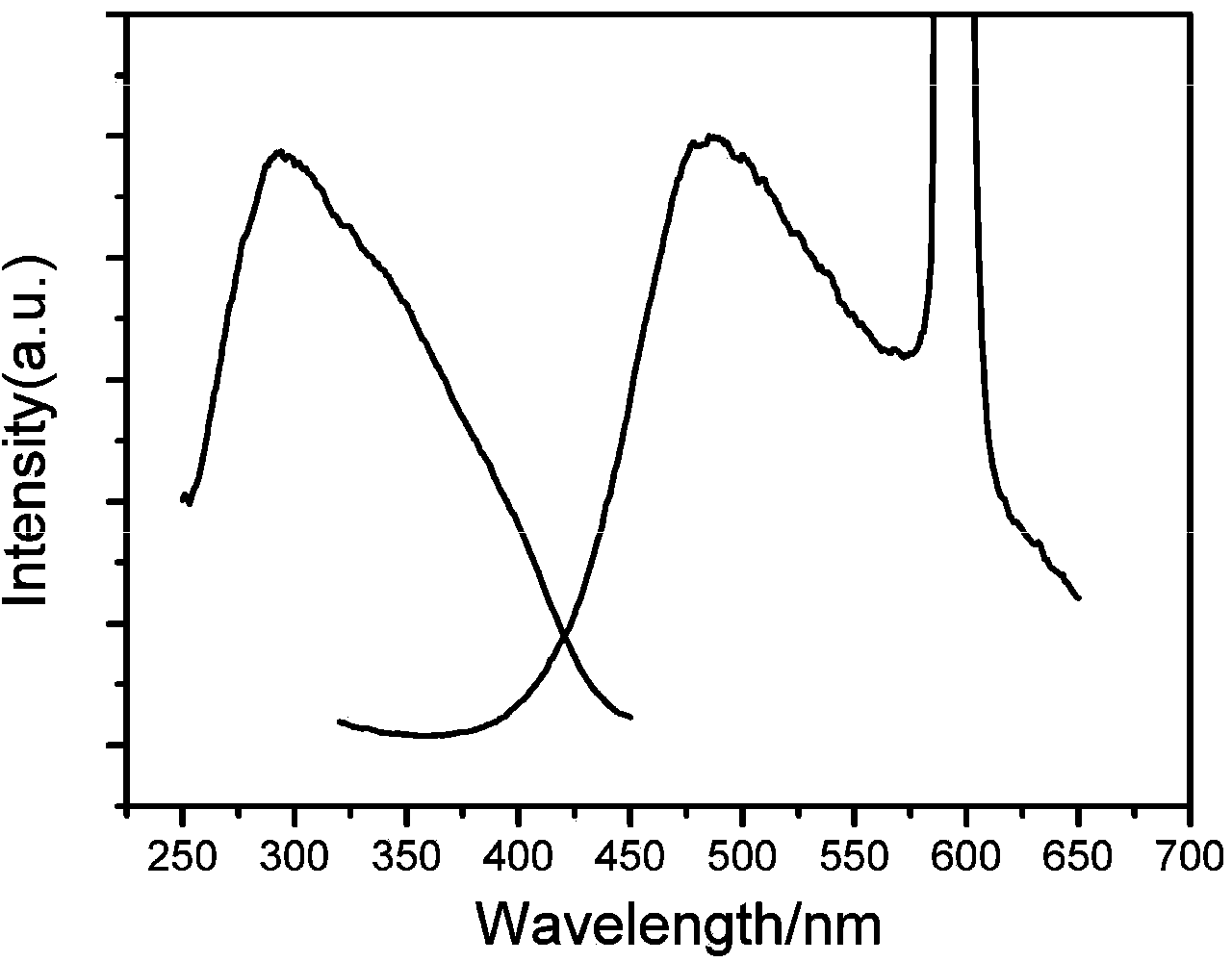

Embodiment 1

[0021] According to the rare earth-doped aluminum nitride-based blue phosphor chemical formula (1-x-y) AlN: xEu, ySi, take x=0.005, y=0.03, that is, the mole fraction of Eu is 0.5%, and the mole fraction of Si is 3%. Take aluminum powder, silicon powder and europium oxide powder as raw materials, the mass of ammonium fluoride is 20% of the total mass of raw materials, mix aluminum powder, silicon powder, europium oxide powder and ammonium fluoride powder and put them into a mortar and grind until uniform . Put the mixed powder into a BN (boron nitride) porcelain boat; then put the boron nitride porcelain boat into the tube furnace. 99.9% ammonia gas and nitrogen gas with a purity of 99.99% at a rate of 0.3L / min; raise the temperature of the tube furnace from room temperature to 1000°C at a rate of 5°C / min, and then at a rate of 3°C / min To 1450°C, keep warm at this temperature for 2 hours. After the sintering reaction, the product in the BN porcelain boat is taken out and gro...

Embodiment 2

[0024] According to the rare earth-doped aluminum nitride-based blue phosphor chemical formula (1-x-y) AlN: xEu, ySi, take x=0.008, y=0.03, that is, the mole fraction of Eu is 0.8%, and the mole fraction of Si is 3%. Take aluminum powder, silicon powder and europium oxide powder as raw materials, the mass of ammonium fluoride is 20% of the total mass of raw materials, mix aluminum powder, silicon powder, europium oxide powder and ammonium fluoride powder and put them into a mortar and grind until uniform . Put the mixed powder into a BN (boron nitride) porcelain boat; then put the boron nitride porcelain boat into the tube furnace, and after the tube furnace is evacuated to a pressure of less than 10Pa, the purity 99.9% ammonia gas and nitrogen gas with a purity of 99.99% at a rate of 0.1L / min; raise the temperature of the tube furnace from room temperature to 1000°C at a rate of 5°C / min, and then at a rate of 3°C / min To 1450°C, keep warm at this temperature for 2 hours. Aft...

Embodiment 3

[0026] According to the rare earth-doped aluminum nitride-based blue phosphor chemical formula (1-x-y) AlN: xEu, ySi, take x=0.005, y=0.05, that is, the mole fraction of Eu is 0.5%, and the mole fraction of Si is 5%. Take aluminum powder, silicon powder and europium oxide powder as raw materials, the mass of ammonium fluoride is 30% of the total mass of raw materials, mix aluminum powder, silicon powder, europium oxide powder and ammonium fluoride powder and put them into a mortar and grind until uniform . Put the mixed powder into a BN (boron nitride) porcelain boat; then put the boron nitride porcelain boat into the tube furnace. 99.9% ammonia gas and nitrogen gas with a purity of 99.99% at a rate of 1 L / min; the tube furnace is heated from room temperature to 1000 °C at a rate of 5 °C / min, and then to 1000 °C at a rate of 3 °C / min 1450°C, keep warm at this temperature for 2 hours. After the sintering reaction, the product in the BN porcelain boat is taken out and ground t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com