Hoist-driven discrete material anti-delamination storage system

A storage system and winch technology, which is applied in the field of winch-driven discrete material anti-layered storage systems, can solve the problems of occupying the internal space of the silo and affecting the material collection operation, and achieves easy control, reasonable design, and reduced friction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

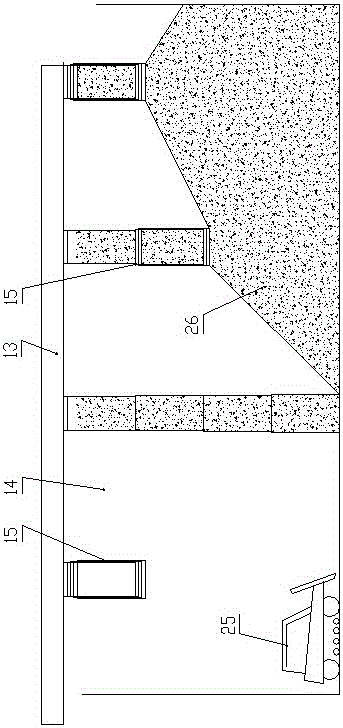

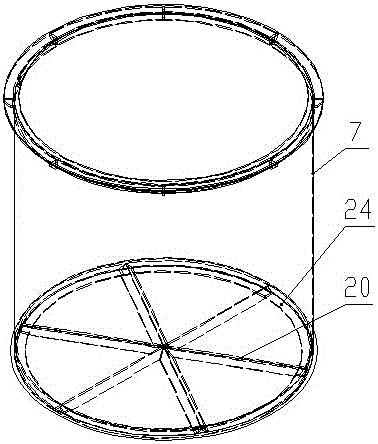

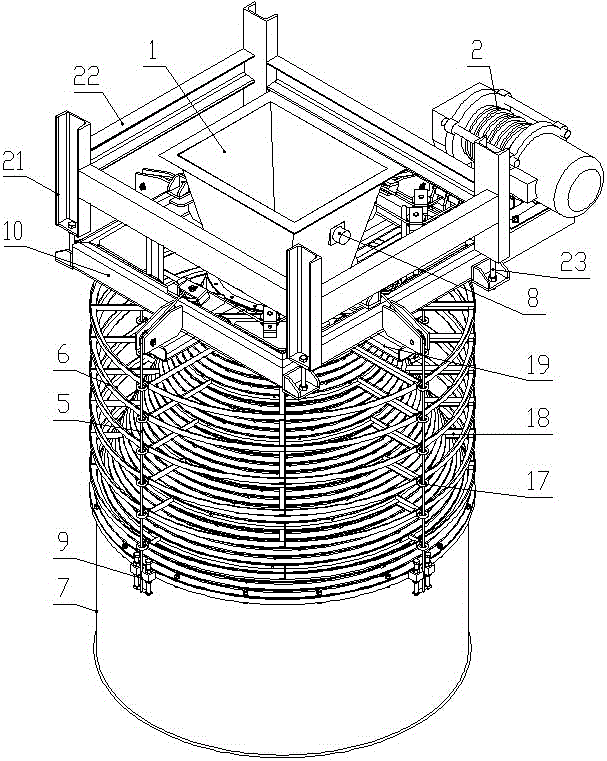

[0038] Such as Figure 1-Figure 10 As shown, the hoist-driven discrete material anti-delamination storage system of the present invention includes a warehouse 14, a scraper conveyor 13 is arranged horizontally on the top of the warehouse 14, a pipeline telescopic distribution machine 15 is arranged in the warehouse 14, and a pipeline telescopic distribution machine 15 includes an installation frame 10, the installation frame 10 is connected to the bottom of the scraper conveyor 13 through a detachable connection structure, the installation frame 10 is provided with a lifting device, and the lifting device includes a four-winch hoist 2, a flat guide wheel group 4-1, Horizontal reversing wheel 4-2, inclination reversing wheel 4-3, lifting pulley 4-4 and four steel wire ropes 5, one end of four steel wire ropes 5 is respectively fixed and wound on a capstan on the four capstan hoisting machine 2, so The other ends of the four steel wire ropes 5 are respectively connected with a t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com