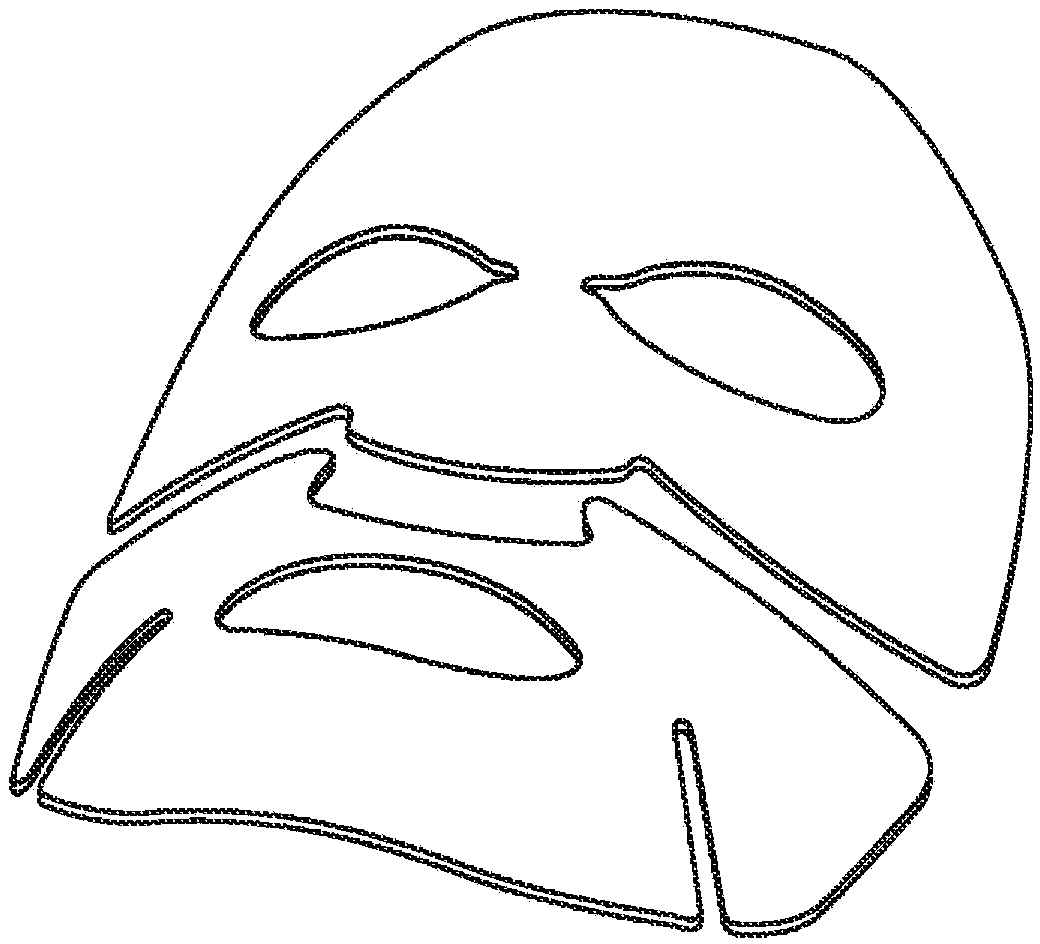

Mask pack

A technology of facial mask and nanofiber layer, applied in the directions of packaged food, packaged item type, head bandage, etc., can solve the problems of facial skin surface detachment, etc., and achieve the effect of improving the phenomenon of nanofiber layering.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

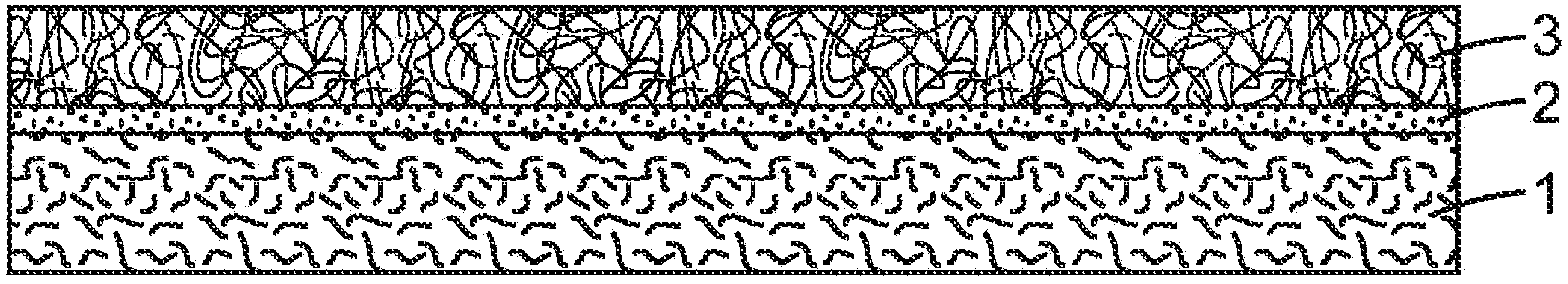

[0047] First, rayon PET spunlace (60 gsm) comprising viscose rayon and PET (weight ratio 8:2) (Namyang Textile Co., Ltd.) was prepared as a nonwoven fabric.

[0048] A polyurethane adhesive (0.3 g) was coated on the nonwoven to form a polyurethane adhesive coated rayon PET hydroentangled nonwoven.

[0049] A solution of PAN (6.30 g), hydrophilic PU (3.15 g), hot-melt PU (1.04 g) and pigment (0.01 g) in dimethylacetamide (89.5 g) was applied to the adhesive by electrospinning. On the nonwoven fabric coated with the mixture, the nanofiber coated nonwoven fabric is completed. At this time, the mass per unit area of the nanofiber layer was adjusted to 0.4, 0.8, or 1.1 gsm.

[0050] The nanofiber-coated nonwoven was cut, and the resulting nonwoven sample was folded twice and placed in the shell of the facial mask. Then, a liquid cosmetic preparation (22 g, HongSam C&Tech) was incorporated into the case. The resulting packages were sealed and stored at room temperature for 3 da...

example 2

[0052] A nonwoven fabric sample obtained by the same procedure as Example 1 (except that the nanofibers have a mass per unit area of 0.3 gsm or 1.3 gsm) was folded twice and placed in the shell of the facial mask. Then, a liquid cosmetic preparation (22 g, HongSam C&Tech) was incorporated into these shells. The resulting package was sealed and stored at room temperature for 30 minutes to prepare the desired mask samples.

example 3

[0054] A nonwoven fabric sample obtained in the same procedure as in Example 1 was folded twice and placed in the shell of the facial mask. Then, a liquid cosmetic preparation (22 g, HongSam C&Tech) was incorporated into these shells. The resulting package was sealed and stored at room temperature for one day to prepare the desired mask samples.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com