Horizontal Extraction and Return Extensions in liquid storage tanks

a liquid storage tank and horizontal extraction technology, applied in the direction of fluid heaters, lighting and heating apparatus, transportation and packaging, etc., can solve the problems of no practical limitation preventing incorporation, large liquid storage tanks are usually unpressurized, and high storage volume, so as to enhance thermal stratification within the tank, reduce or eliminate flow velocity, and facilitate connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

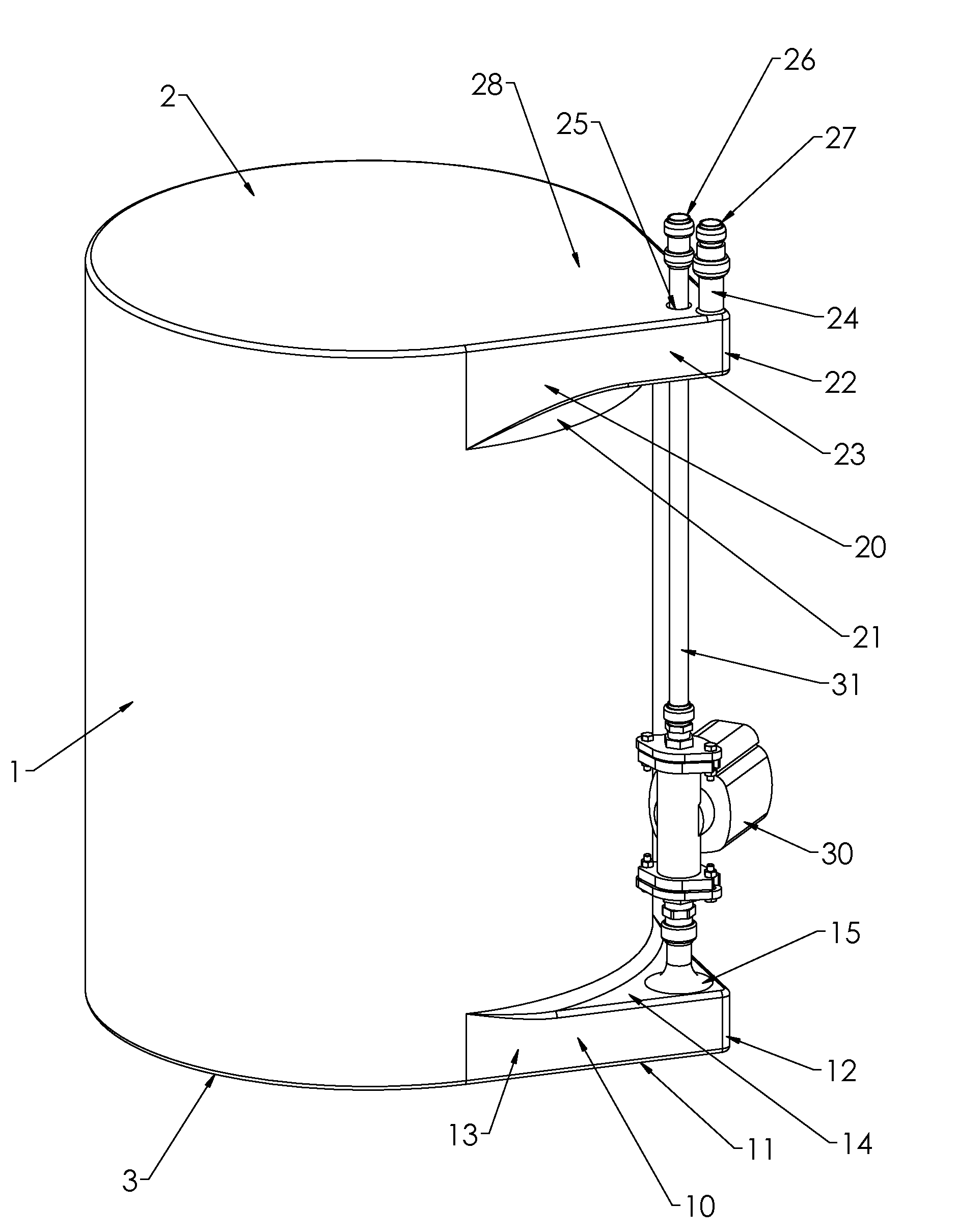

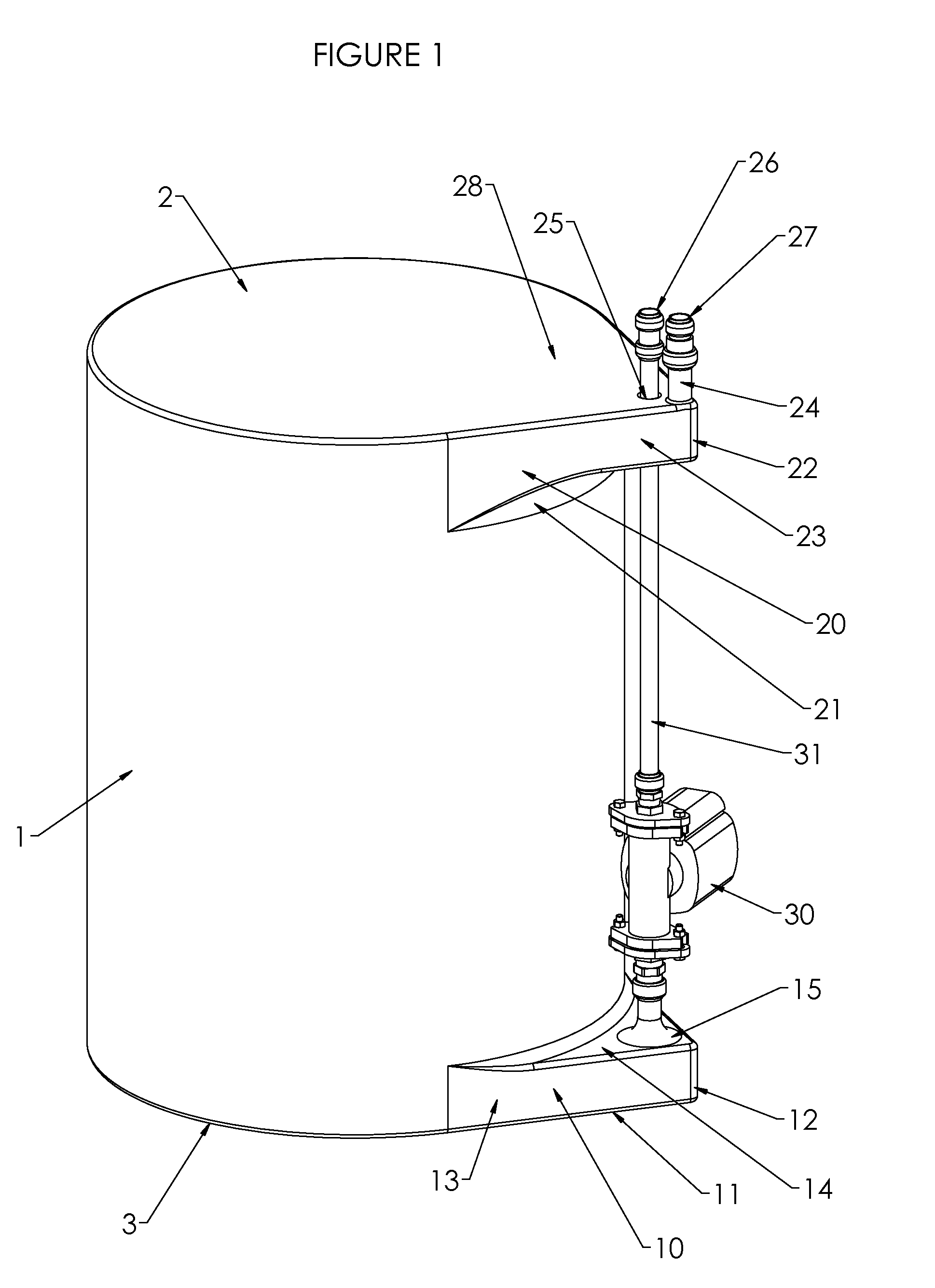

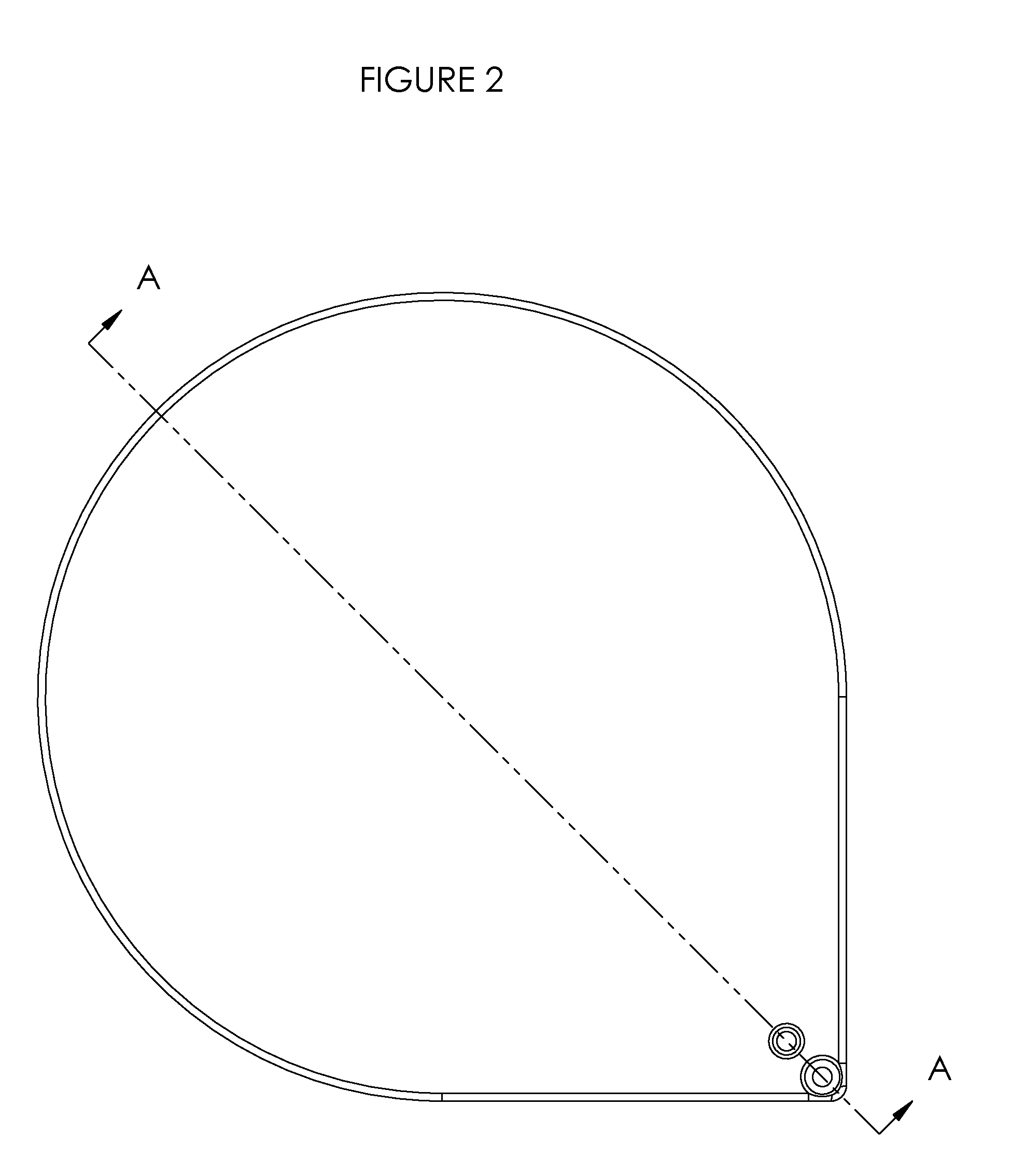

[0026]The tank 1 is a vertical-axis cylinder with planar top 2 and bottom 3; and with relatively thin, hollow bottom and top extensions 10 and 20. The bottom extension 10 has its bottom surface 11 co-planar with the tank bottom 3. The extension 10 comprises vertical surfaces 13 that extend tangentially from the circumference of the tank 1 and meet approximately at a right angle at a vertical extension corner 12. From the upper horizontal surface 14 of the bottom extension 10 extends a vertical pipe connection 15 that flares smoothly from flat to an upward vertical cylindrical shape that allows connection to the circulating pump 30. The radius of the corner 12 may vary but will normally be less than the radius of the flared pipe connection 15. This design allows the pump 30 to draw water smoothly upward with minimal pressure drop, minimal tendency to draw debris into pump 30, and with transition flow characteristics that minimize the tendency of the pump inlet flow stream to mix the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com