Preparation method of oxidized Mxene/S compound applied to lithium-sulphur battery cathode

A lithium-sulfur battery and composite technology, which is applied in the field of preparation of S composites, can solve the problems of complex preparation methods and processes, and achieve the effects of high cycle stability, high specific capacity and low production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0035] Embodiment 1: This embodiment is a method for preparing an oxidized Mxene / S composite applied to the positive electrode of a lithium-sulfur battery, specifically according to the following steps:

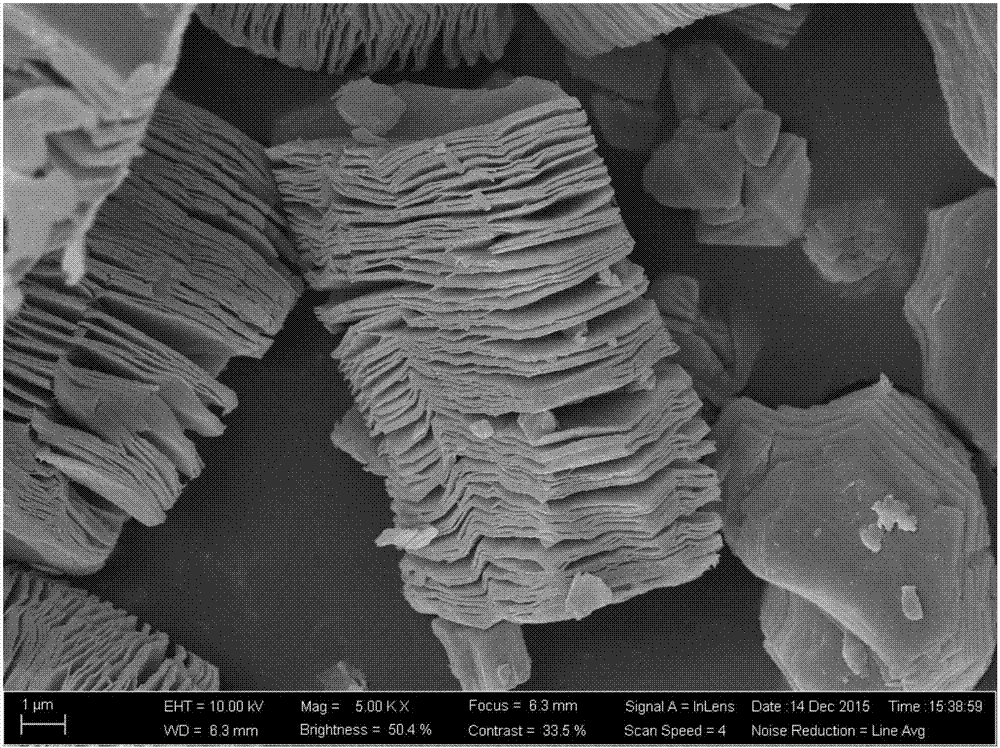

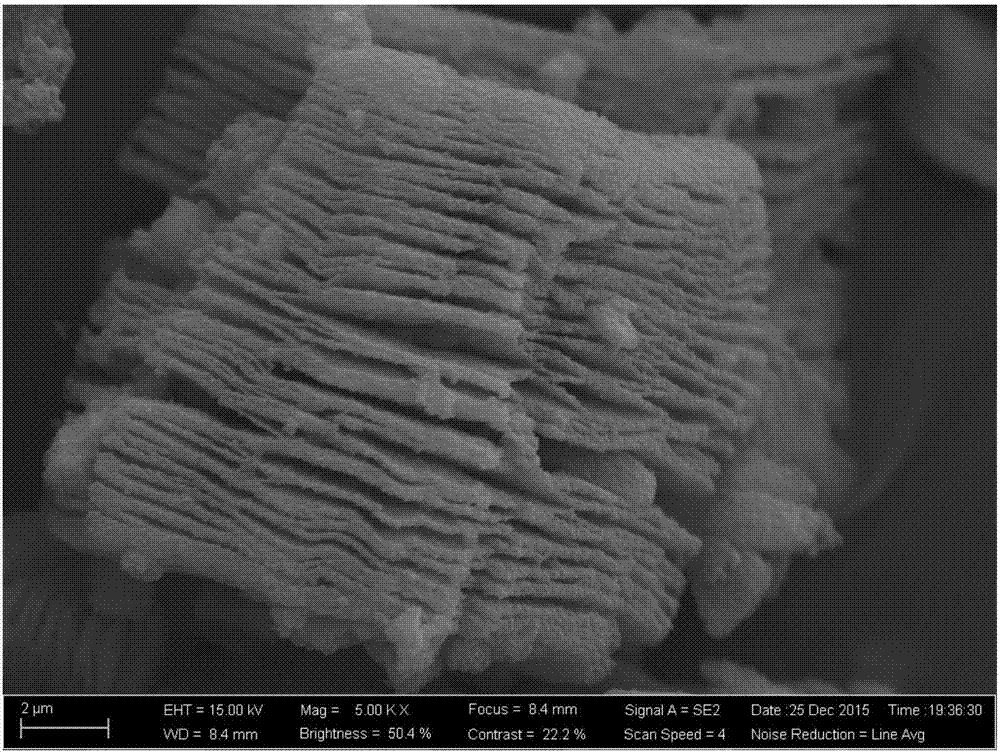

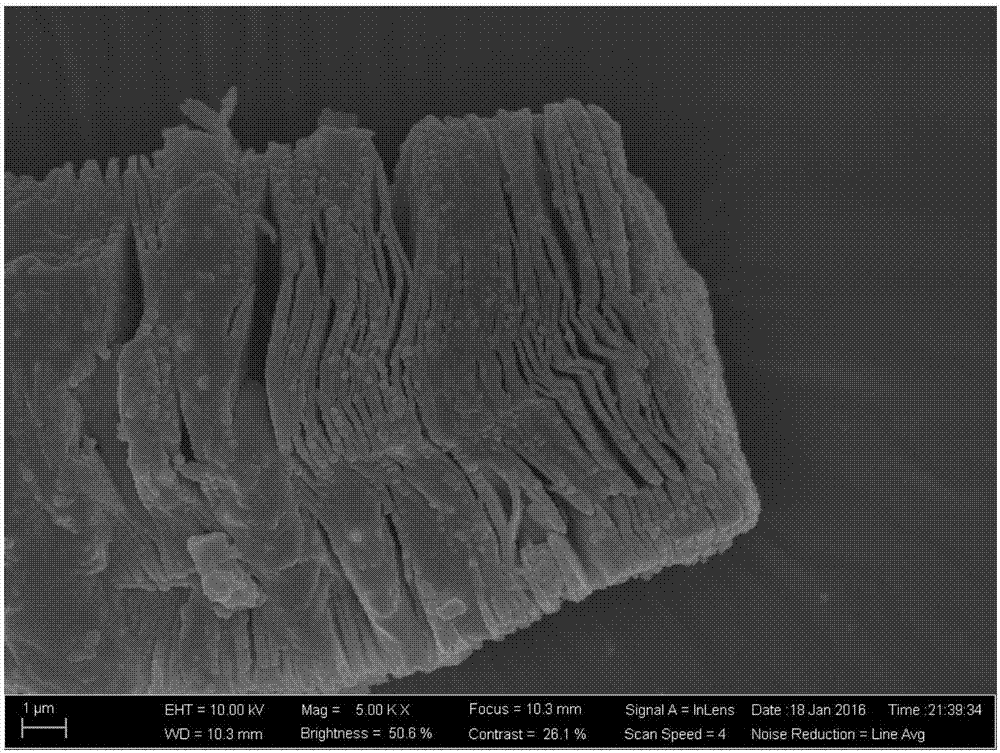

[0036] 1. Preparation of Mxene powder: Mix the MAX phase with the HF solution, stir for 6h to 40h, let it stand for stratification naturally, then centrifuge the precipitate, repeat suction filtration and washing with deionized water and alcohol until the filtrate is neutral, and obtain an accordion after drying Like Mxene powder; The mass of described MAX phase and the volume ratio of HF solution are 1g:(50mL~200mL); The mass concentration of described HF solution is 10%~40%;

[0037] 2. Oxidation: The accordion-shaped Mxene powder was mixed with Ar and O 2 The mixed atmosphere and temperature of 100 ℃ ~ 900 ℃ under the conditions of heat treatment for 2h ~ 20h, in Ar and O 2 Cool to room temperature under the mixed atmosphere, obtain the Mxene powder of surface oxidation; ...

specific Embodiment approach 2

[0039] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the MAX phase is Ti 2 AlC, Ti 3 AlC 2 or Ti 3 SiC 2 . Others are the same as the first embodiment.

specific Embodiment approach 3

[0040] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the S source is sodium thiosulfate or sodium sulfide. Others are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com