Patents

Literature

140results about How to "Improve initial efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

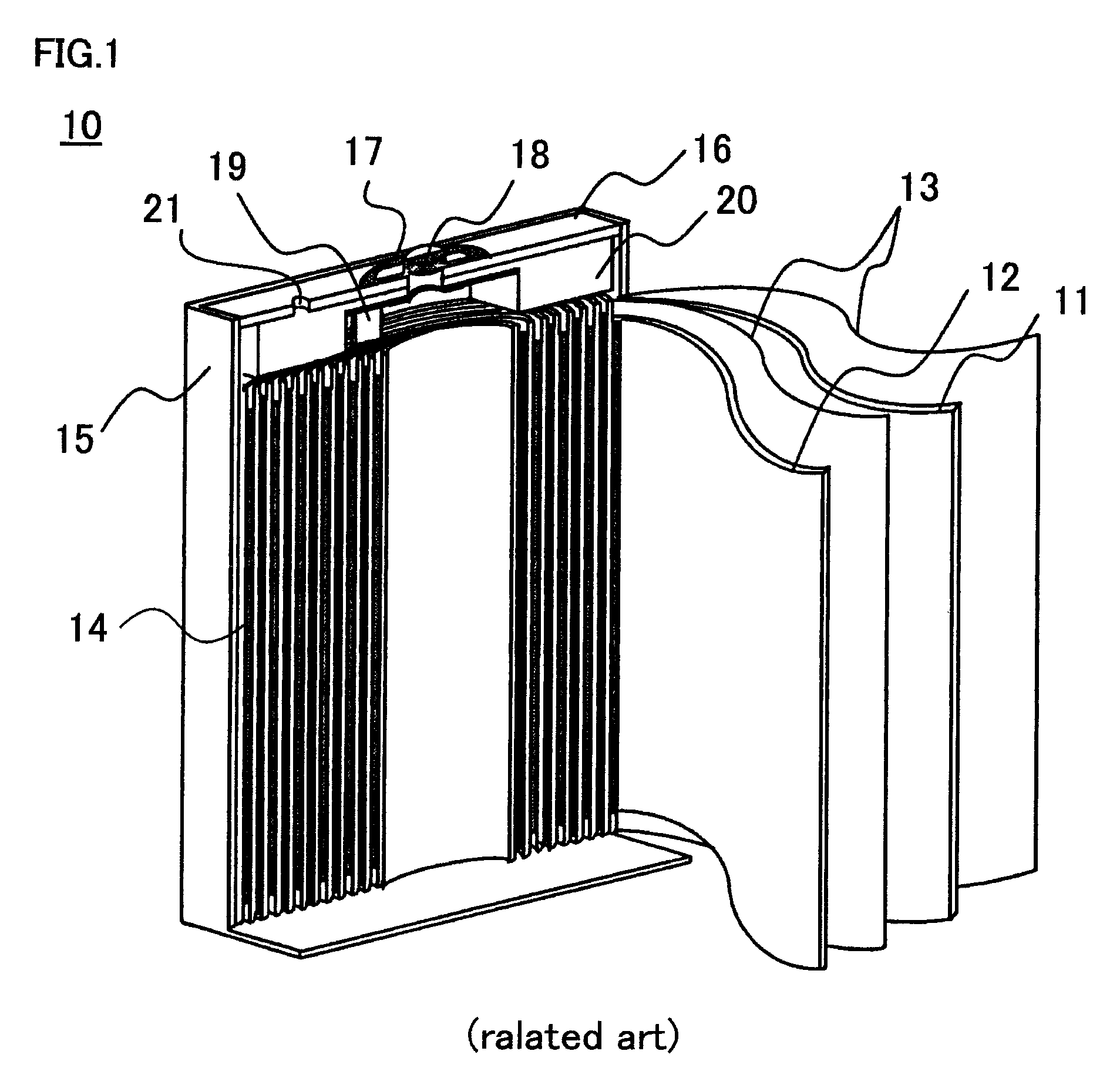

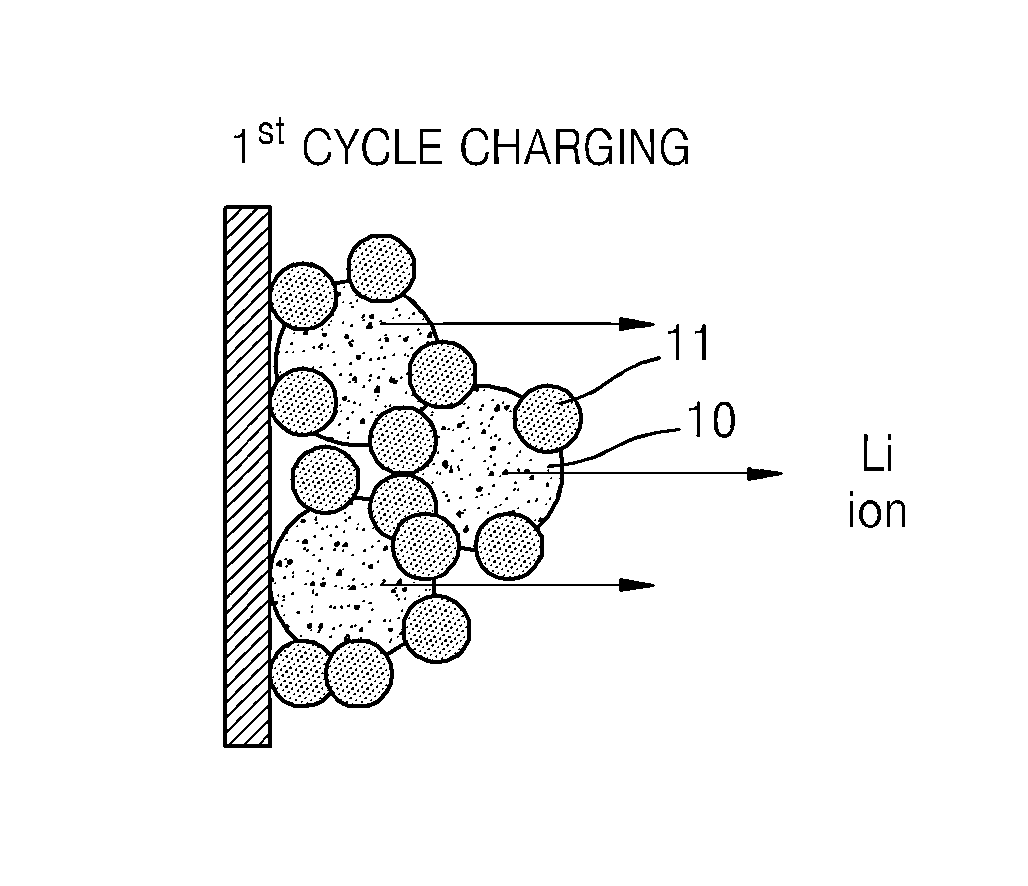

Anode active material and method of preparing the same

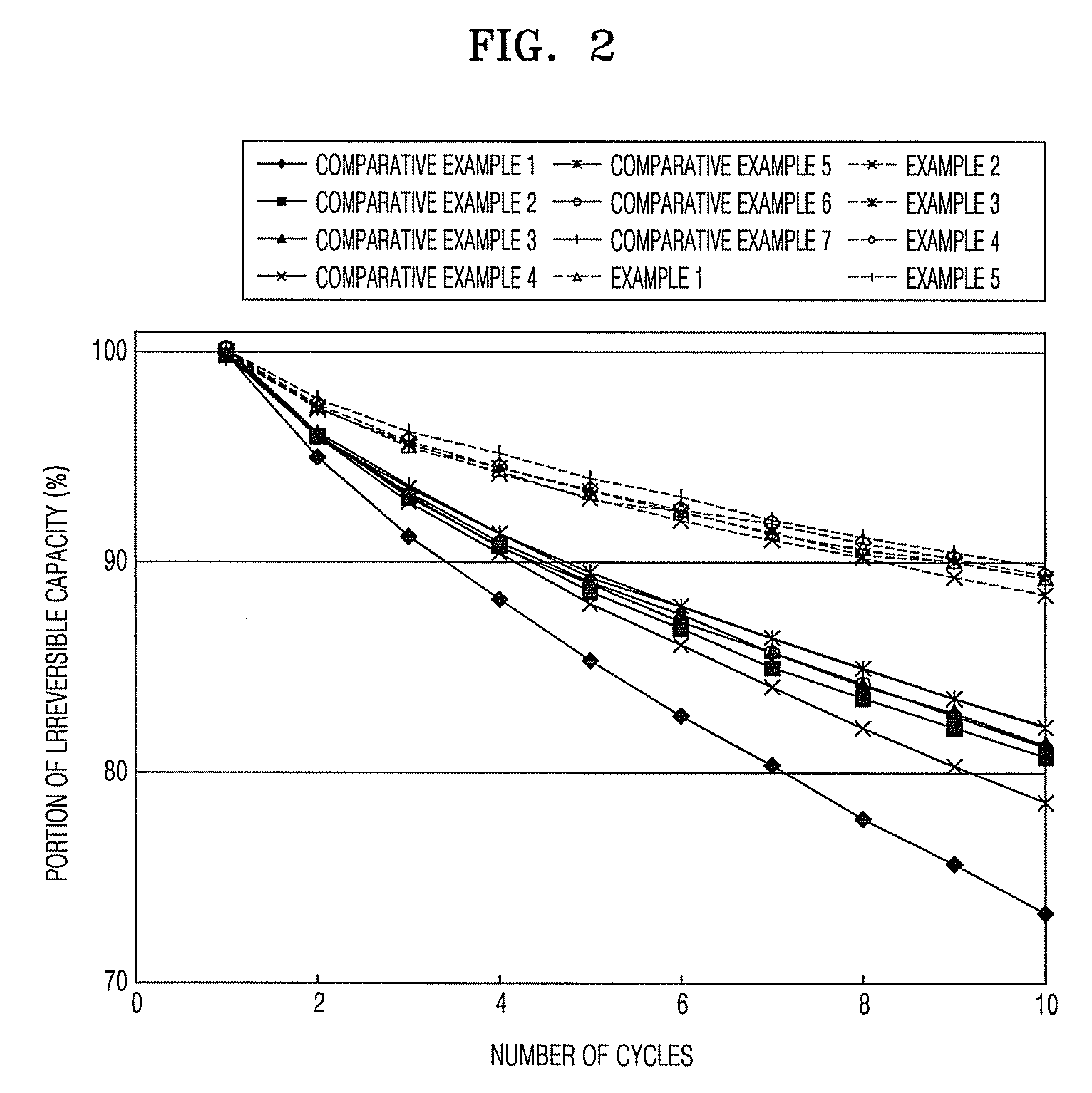

InactiveUS20070243469A1Improving battery cycle characteristicImprove initial efficiencyElectrode thermal treatmentConductive materialMaterials scienceAnode

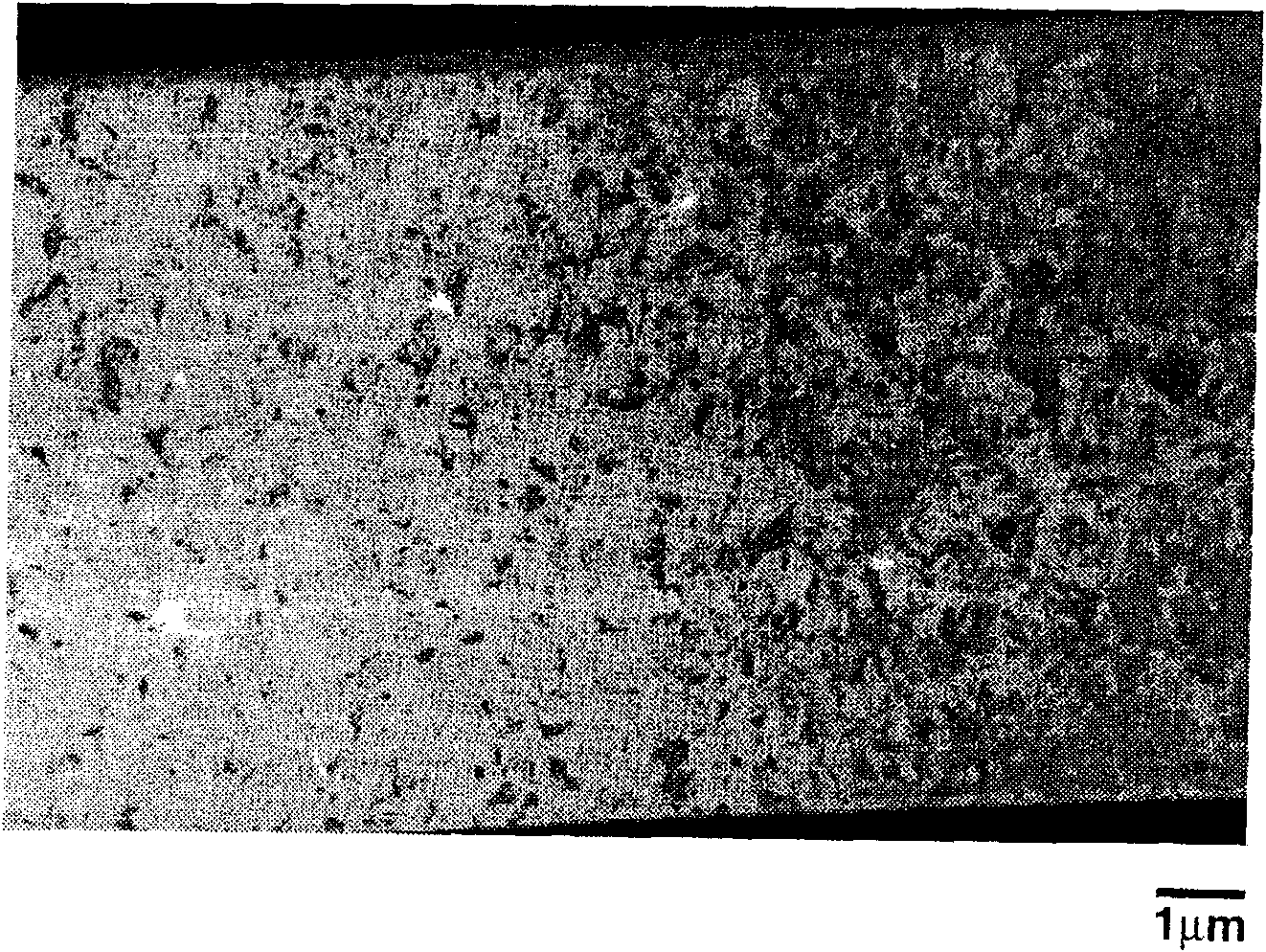

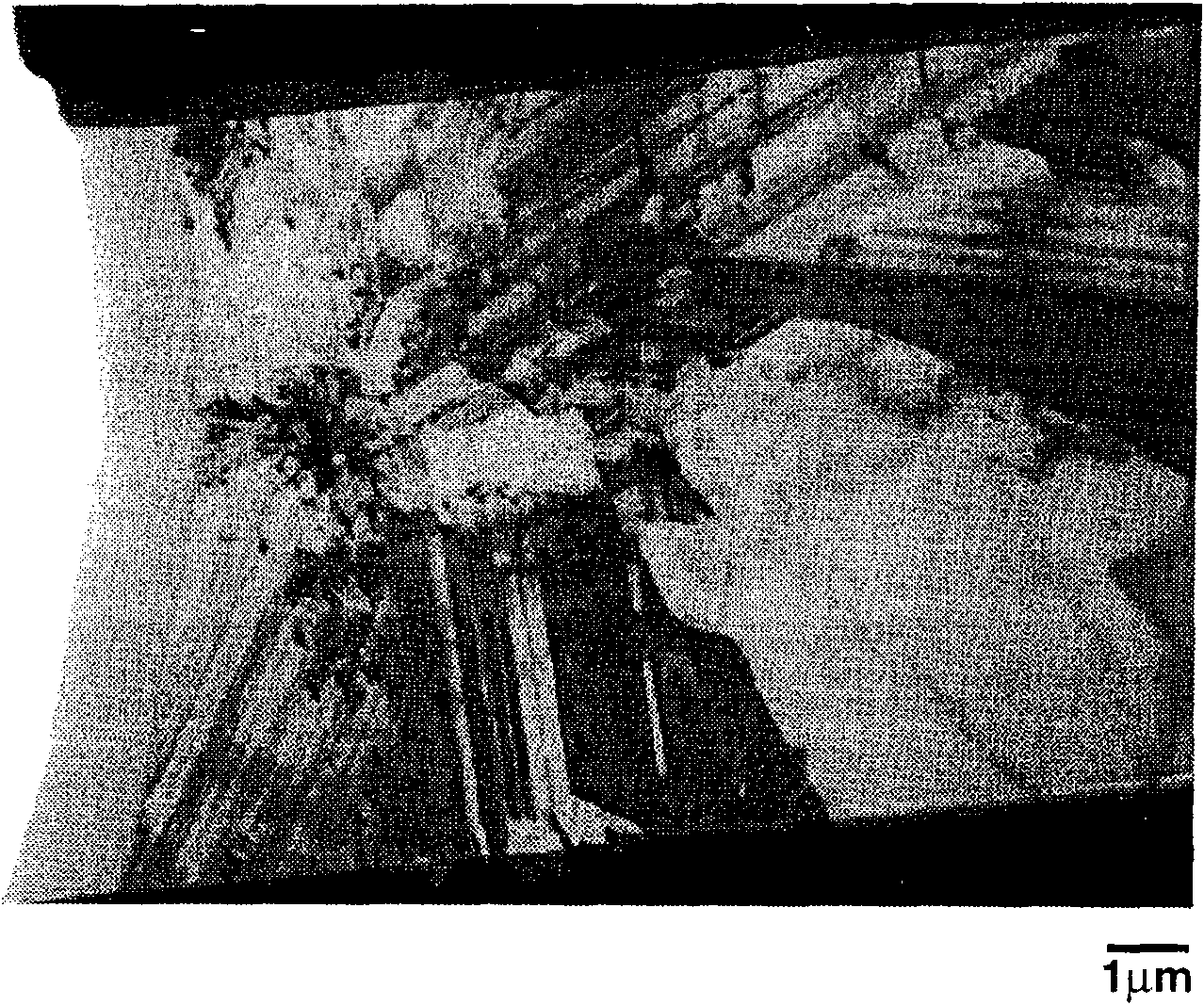

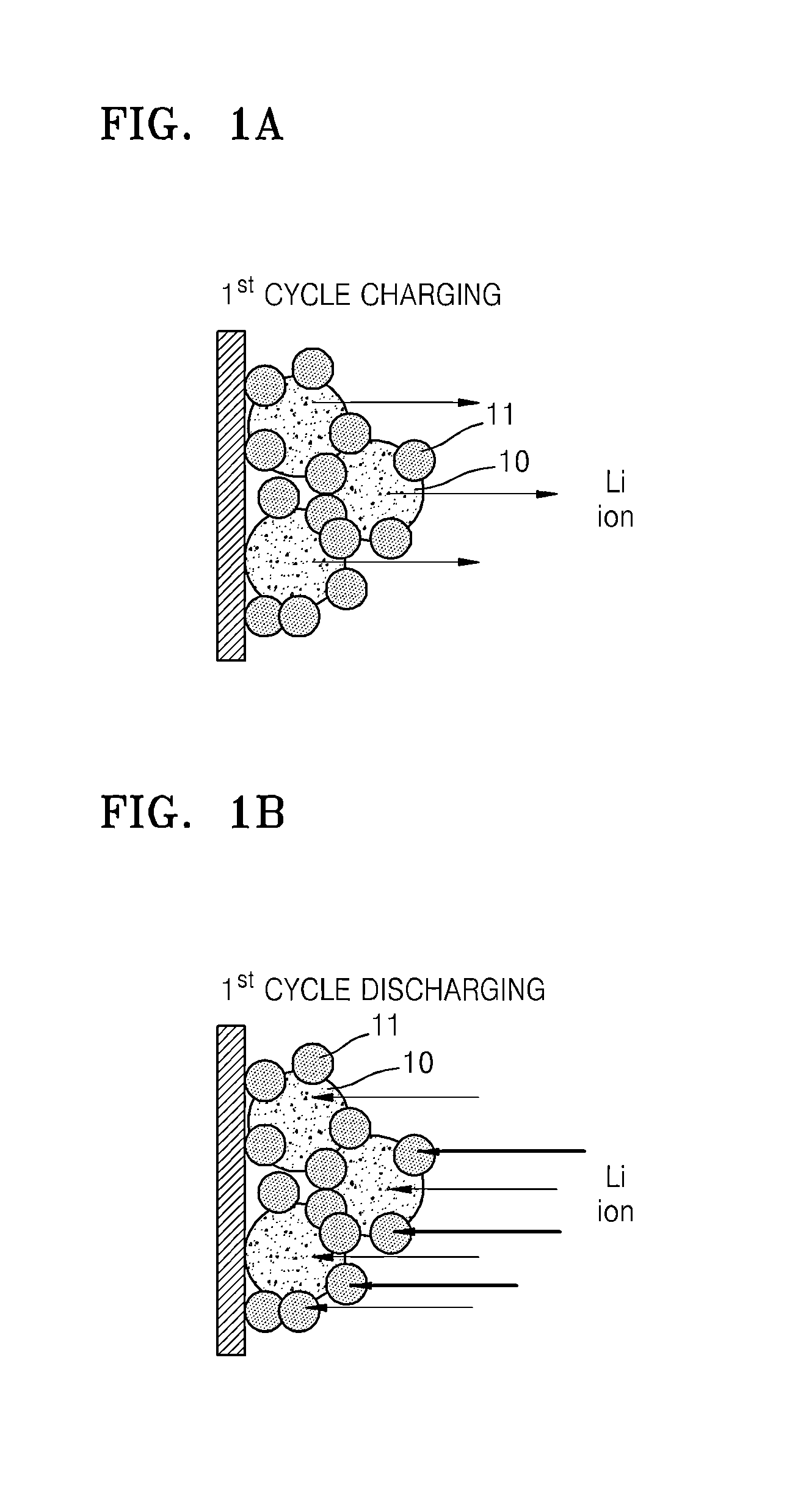

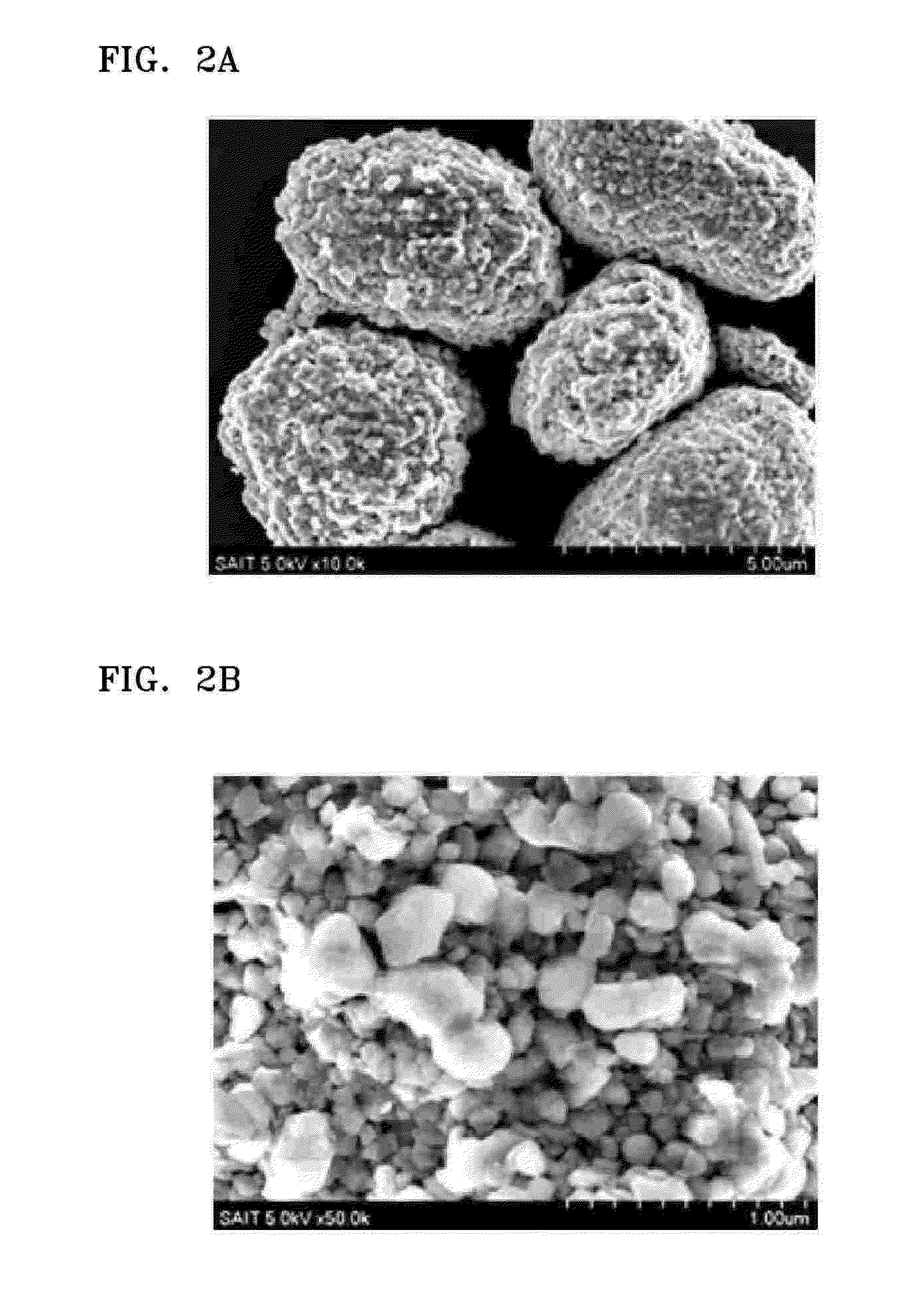

Anode active materials and methods of preparing the same are provided. One anode active material includes a carbonaceous material capable of improving battery cycle characteristics. The carbonaceous material bonds to and coats metal active material particles and fibrous metallic particles to suppress volumetric changes.

Owner:SAMSUNG SDI CO LTD

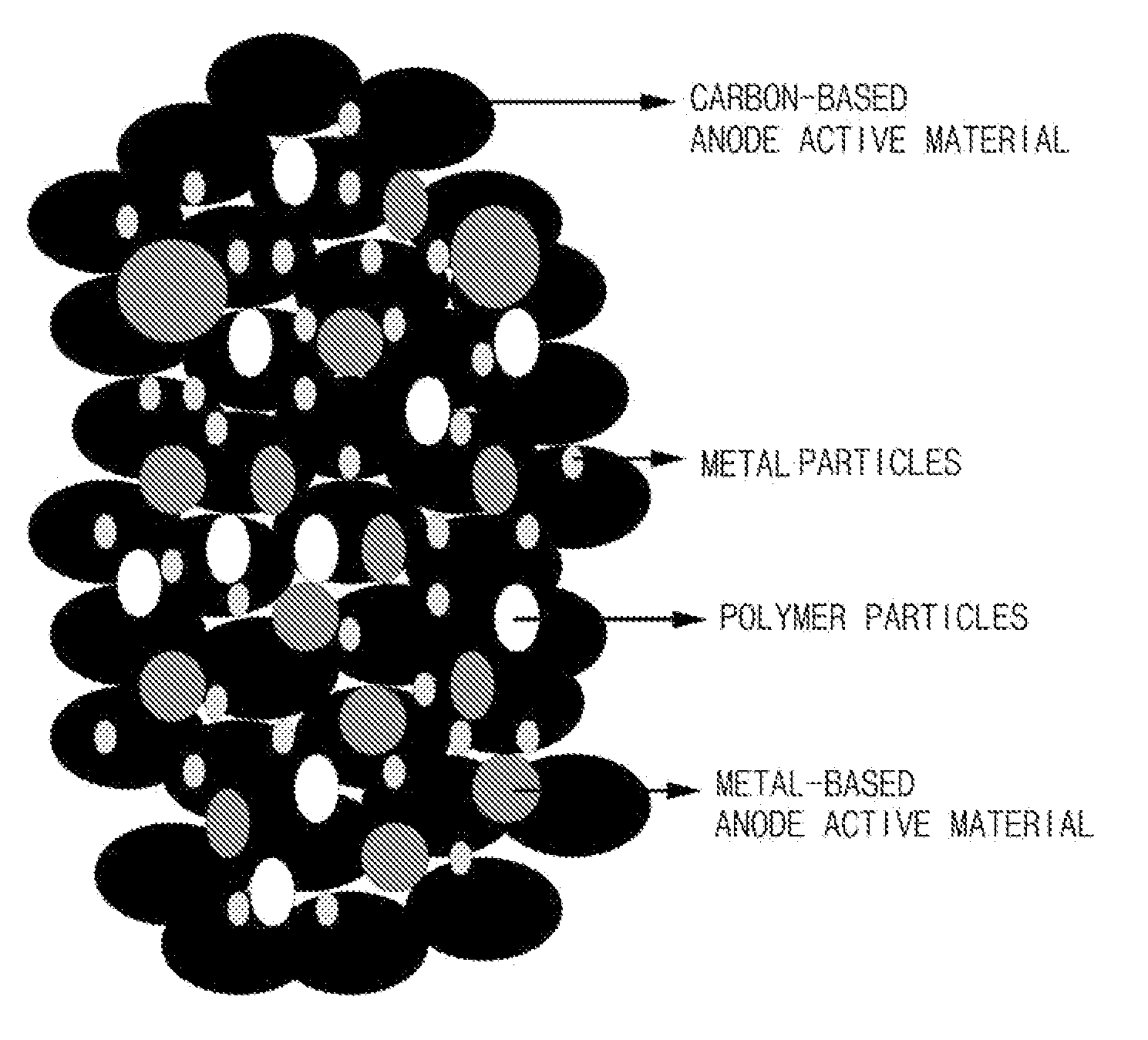

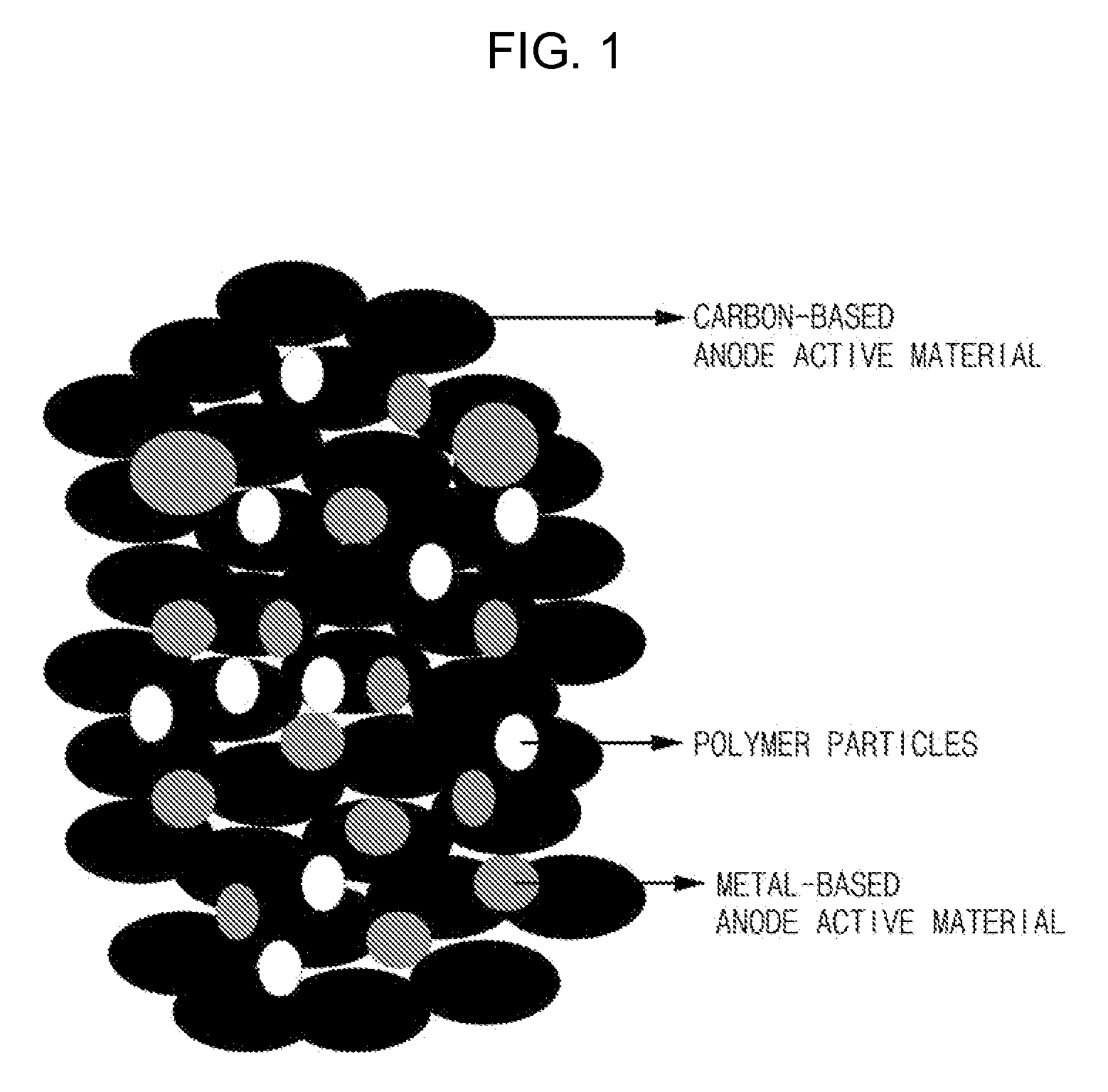

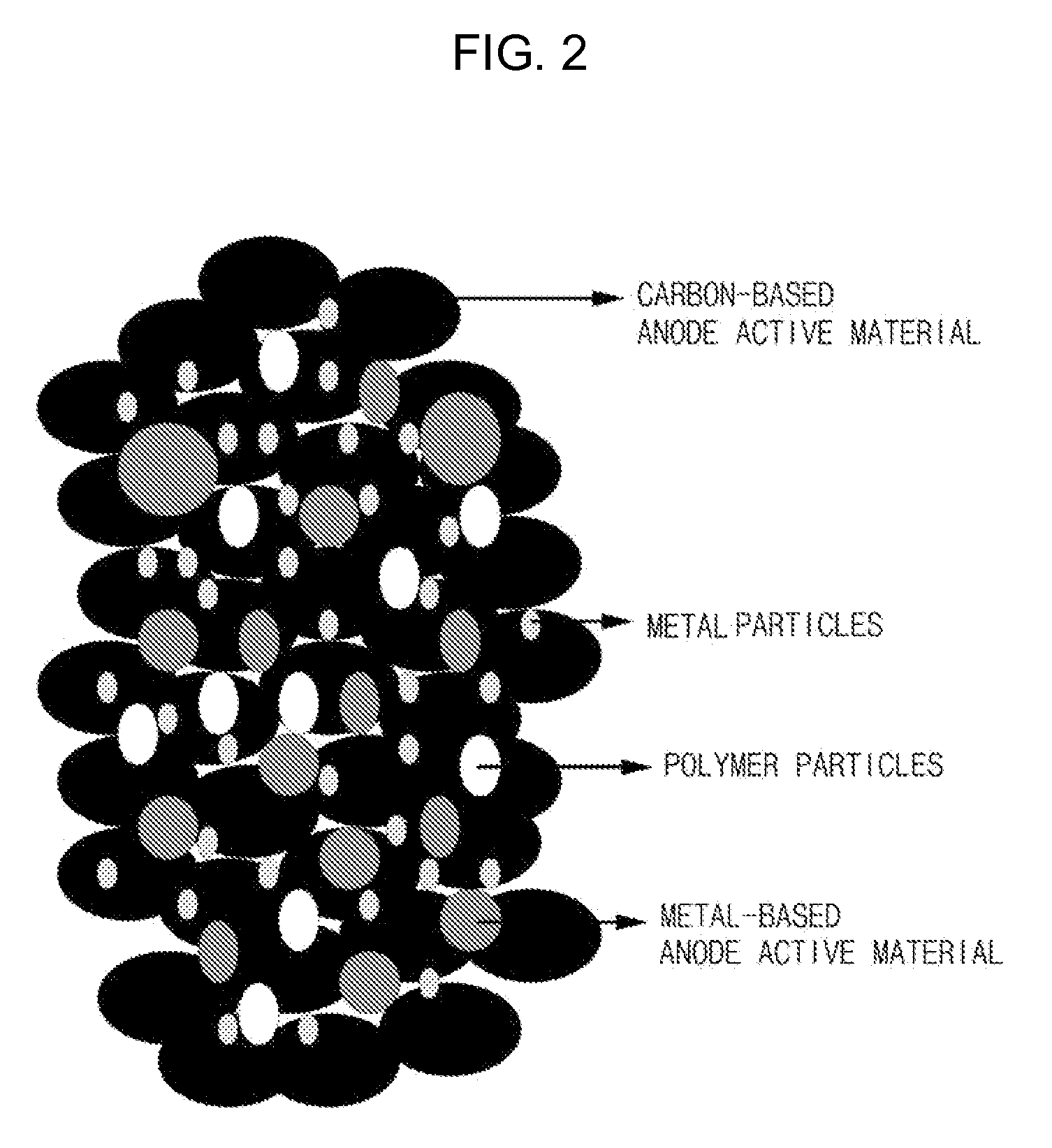

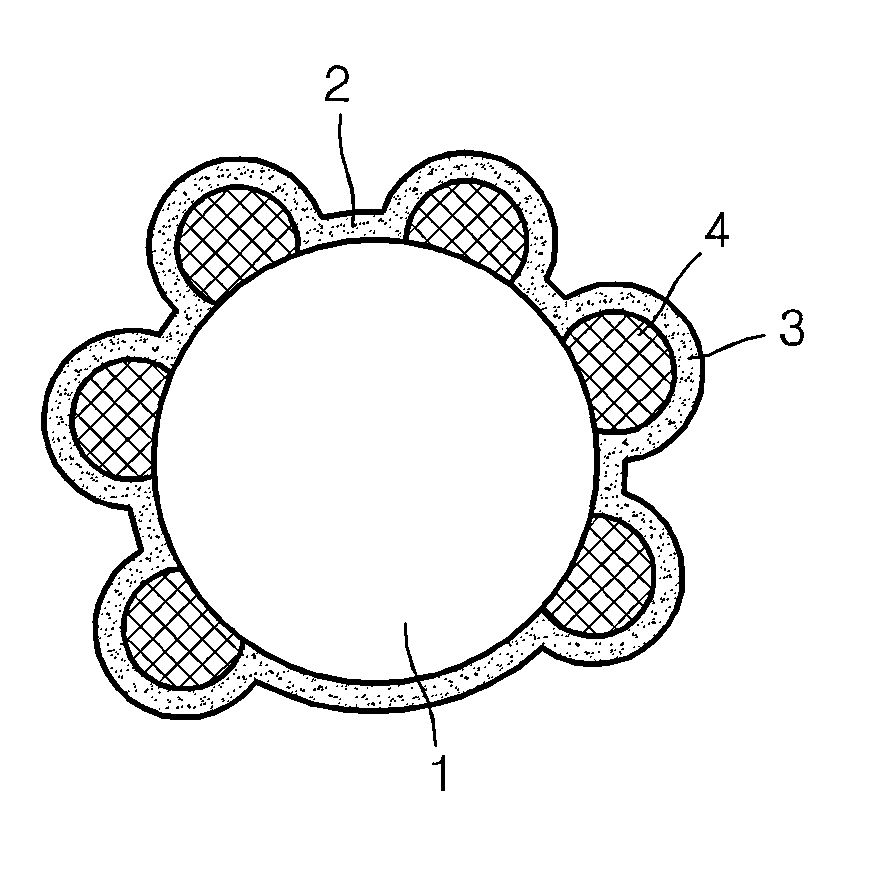

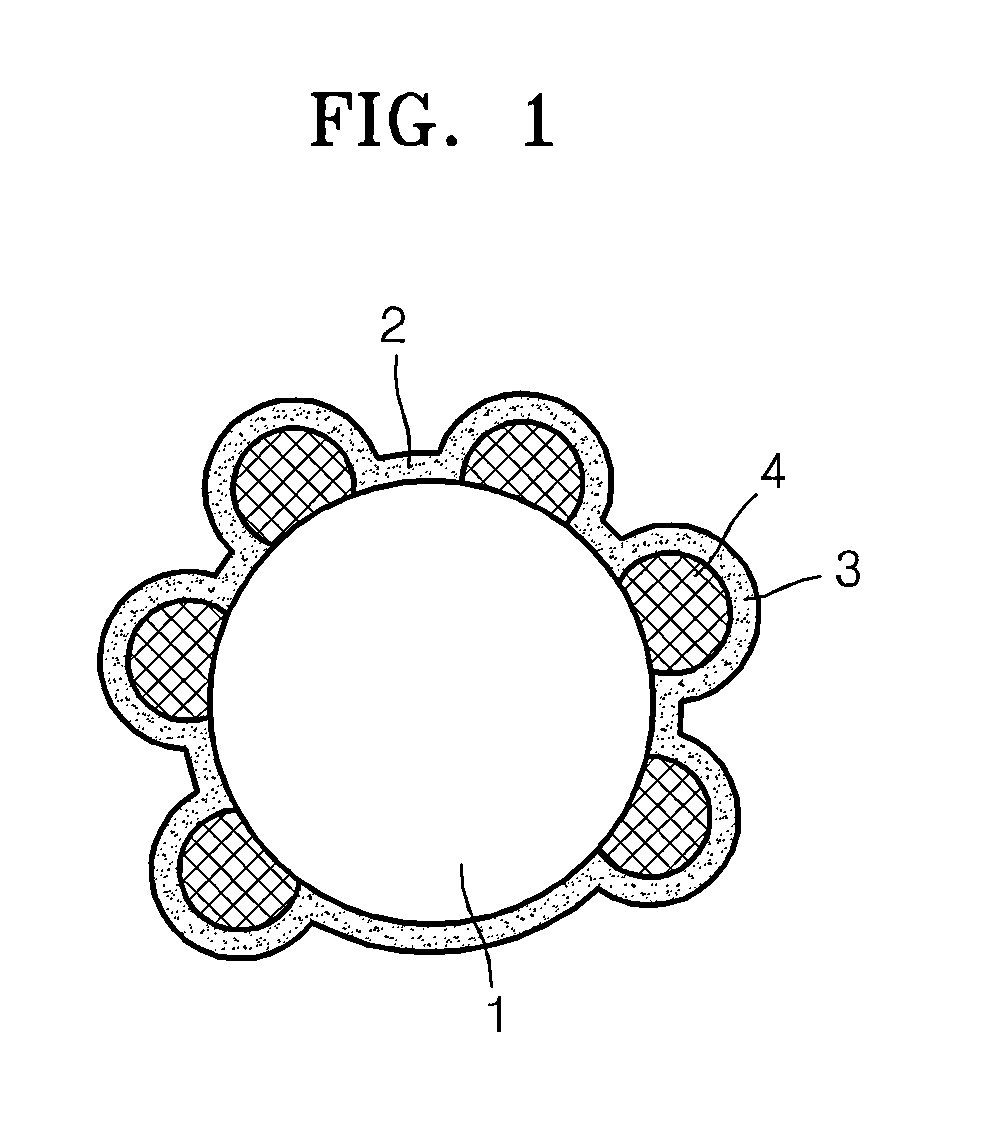

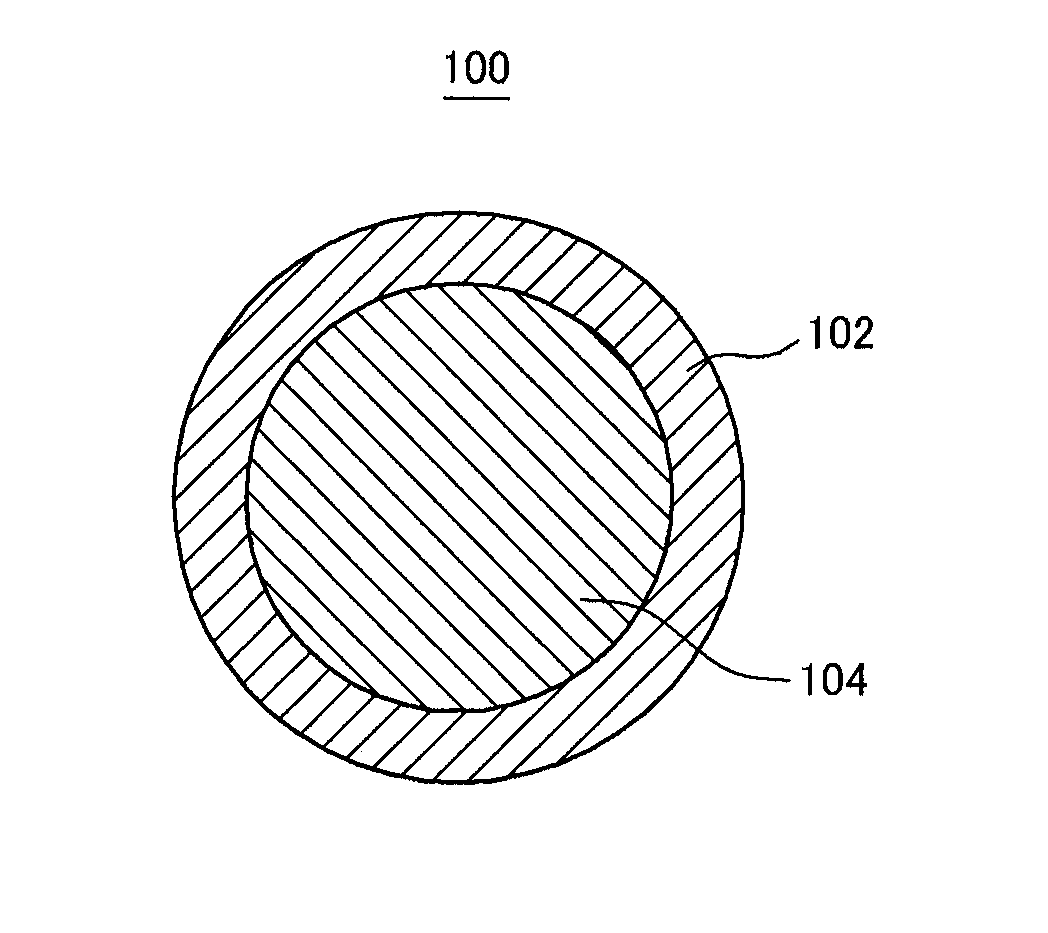

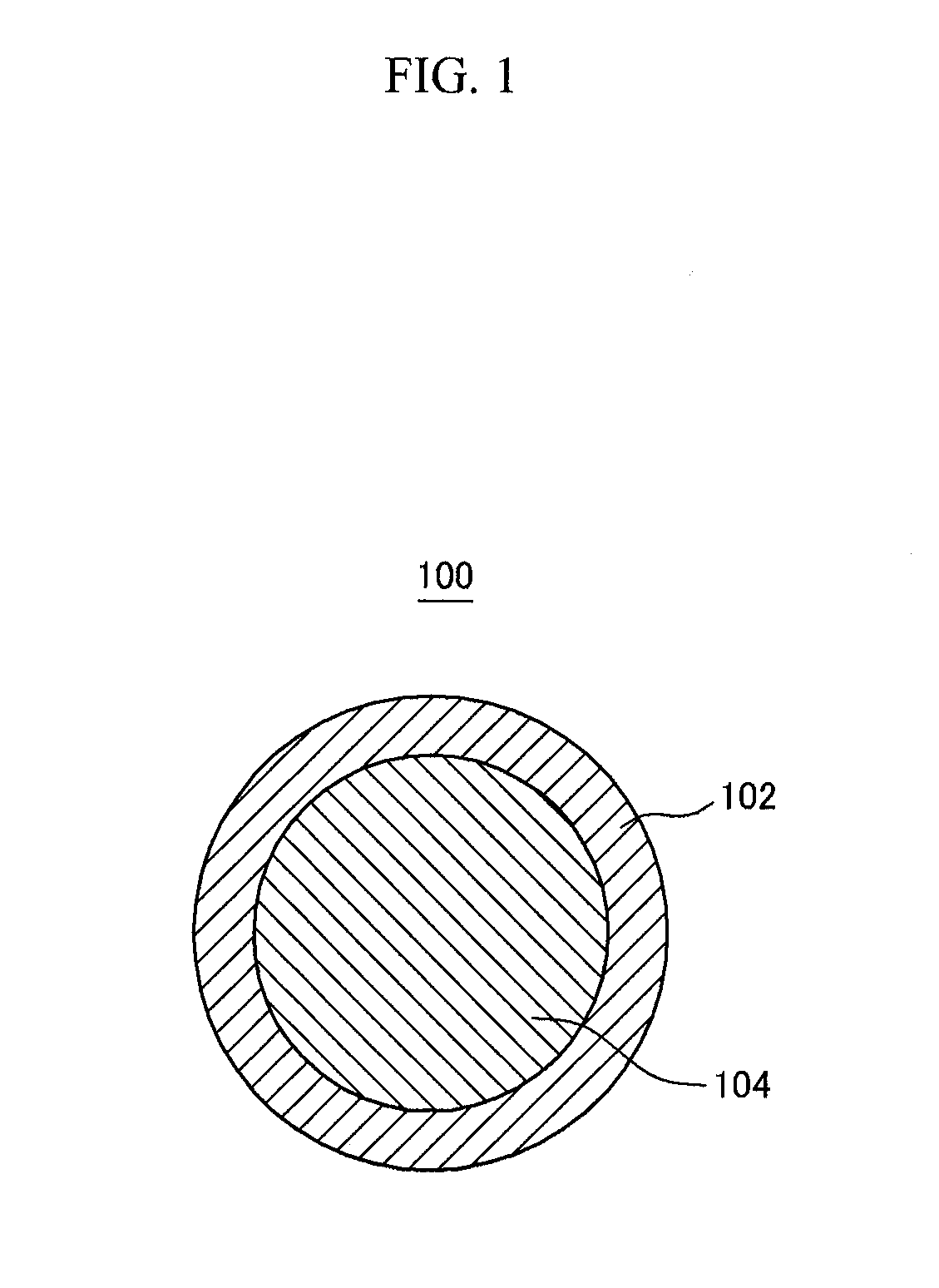

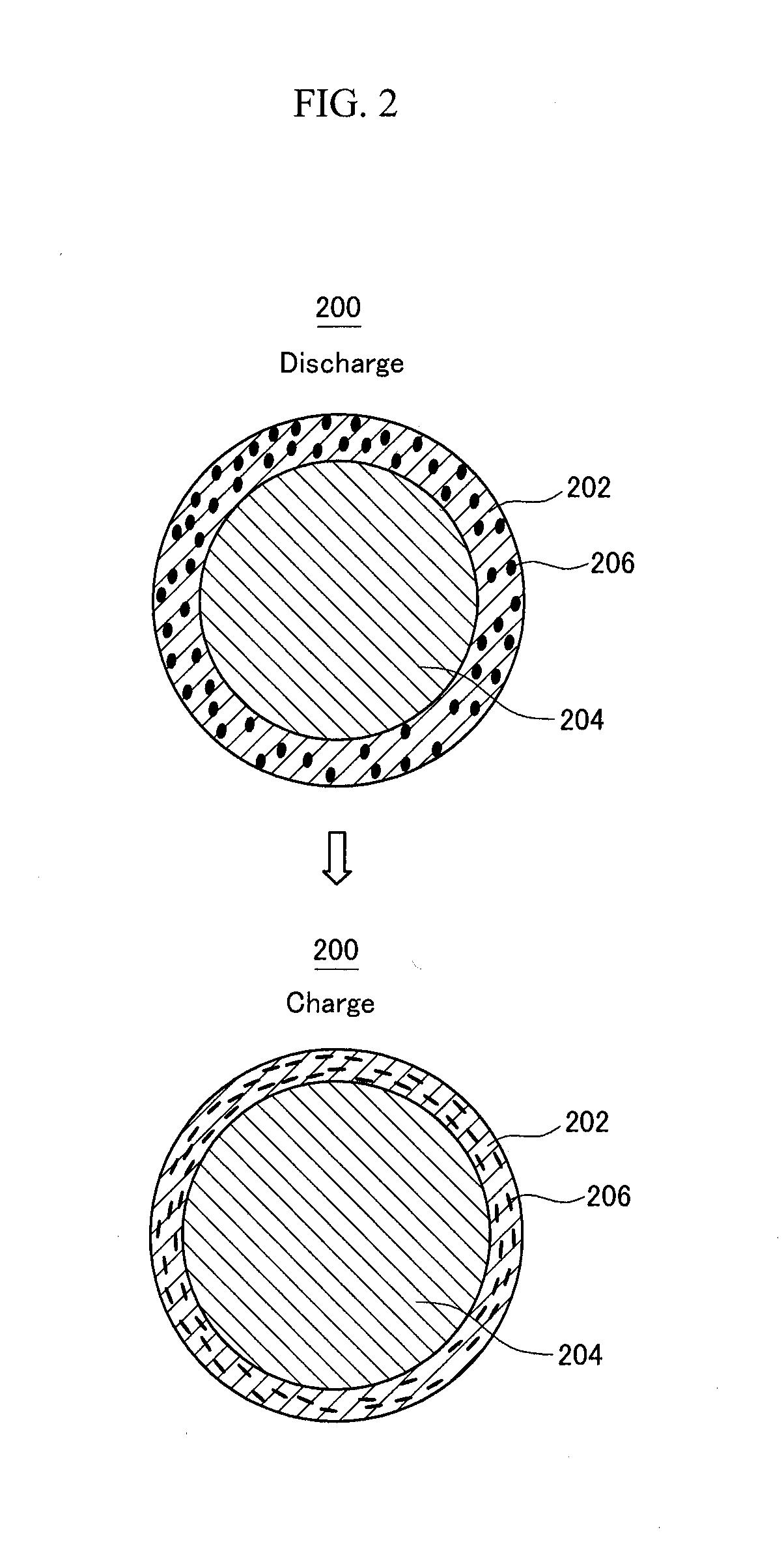

Composite anode active material, anode including the same and lithium battery using the anode

ActiveUS20090023065A1Large capacityEnhanced cycle life performanceFinal product manufactureLi-accumulatorsHigh ratePolymer

A composite anode active material includes a composite of a carbon-based anode active material, a metal-based anode active material and polymer particles. By increasing the conductivity of the composite anode active material, a lithium battery having a large capacity, high initial efficiency, high rate capability and improved cycle life performance can be obtained. An anode includes the composite anode active material and a lithium battery includes the anode.

Owner:SAMSUNG SDI CO LTD

Negative active material for rechargeable lithium battery, and method of preparing the same

ActiveUS20090075173A1High initial capacityImprove initial efficiencyMaterial nanotechnologyElectrode thermal treatmentFree energiesEngineering

An negative active material for a rechargeable lithium battery includes a nano-composite including a Si phase, a SiO2 phase, and a metal oxide phase of formulation MyO, where M is a metal with an oxidation number x, a free energy of oxygen-bond formation ranging from −900 kJ / mol to −2000 kJ / mol, x, and x·y=2. The negative active material for a rechargeable lithium battery according to the present invention can improve initial capacity, initial efficiency, and cycle-life characteristics by suppressing its initial irreversible reaction.

Owner:SAMSUNG SDI CO LTD +1

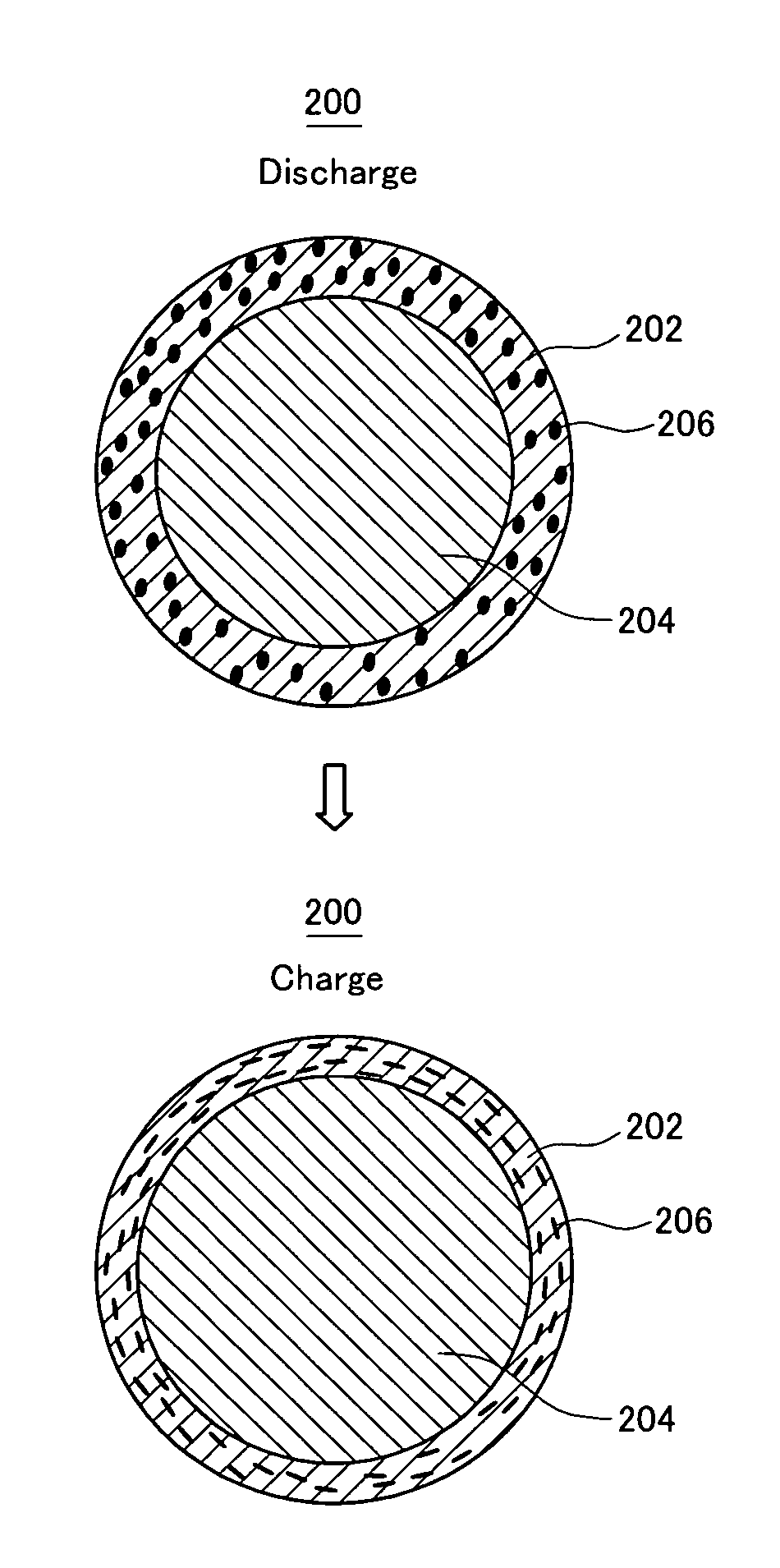

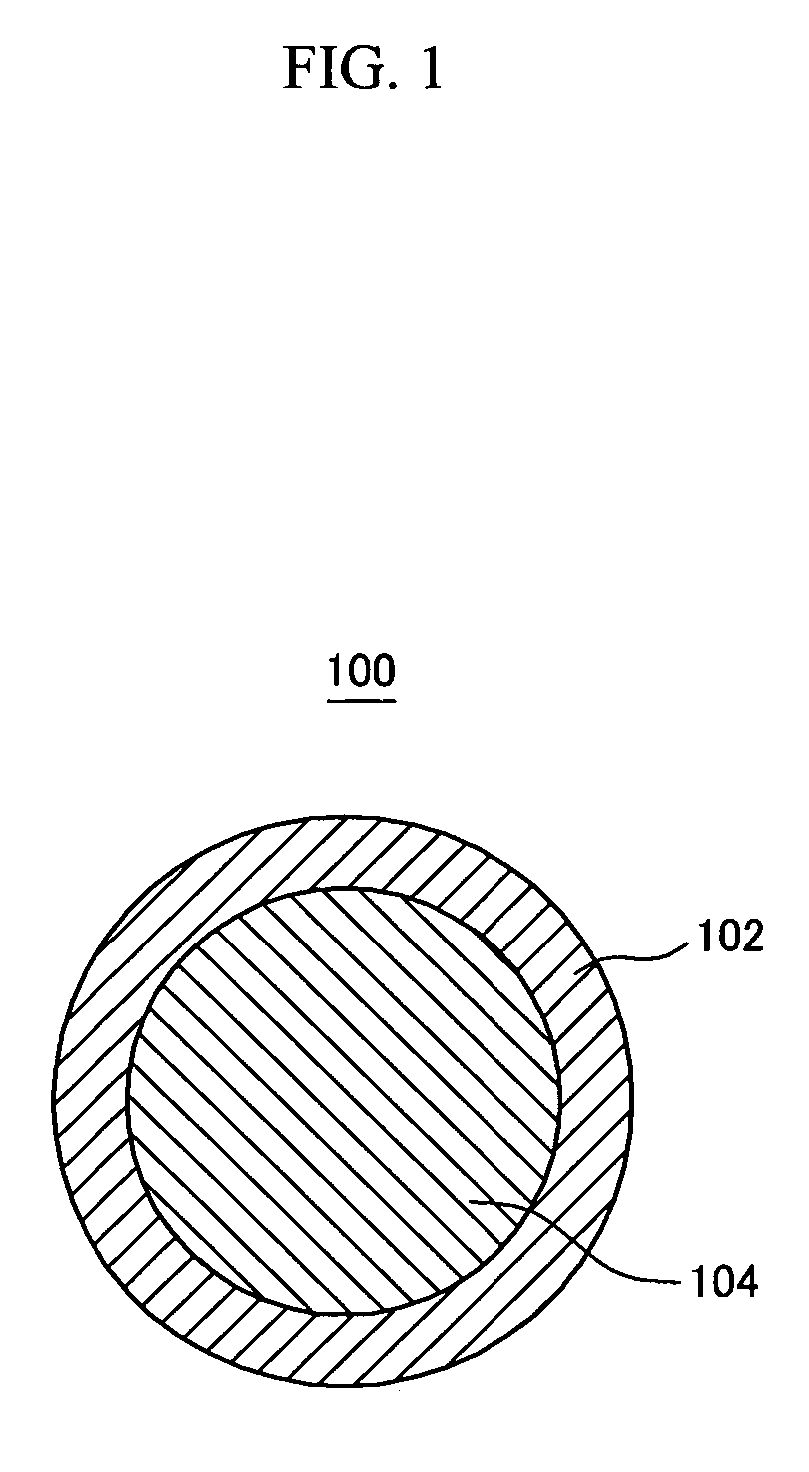

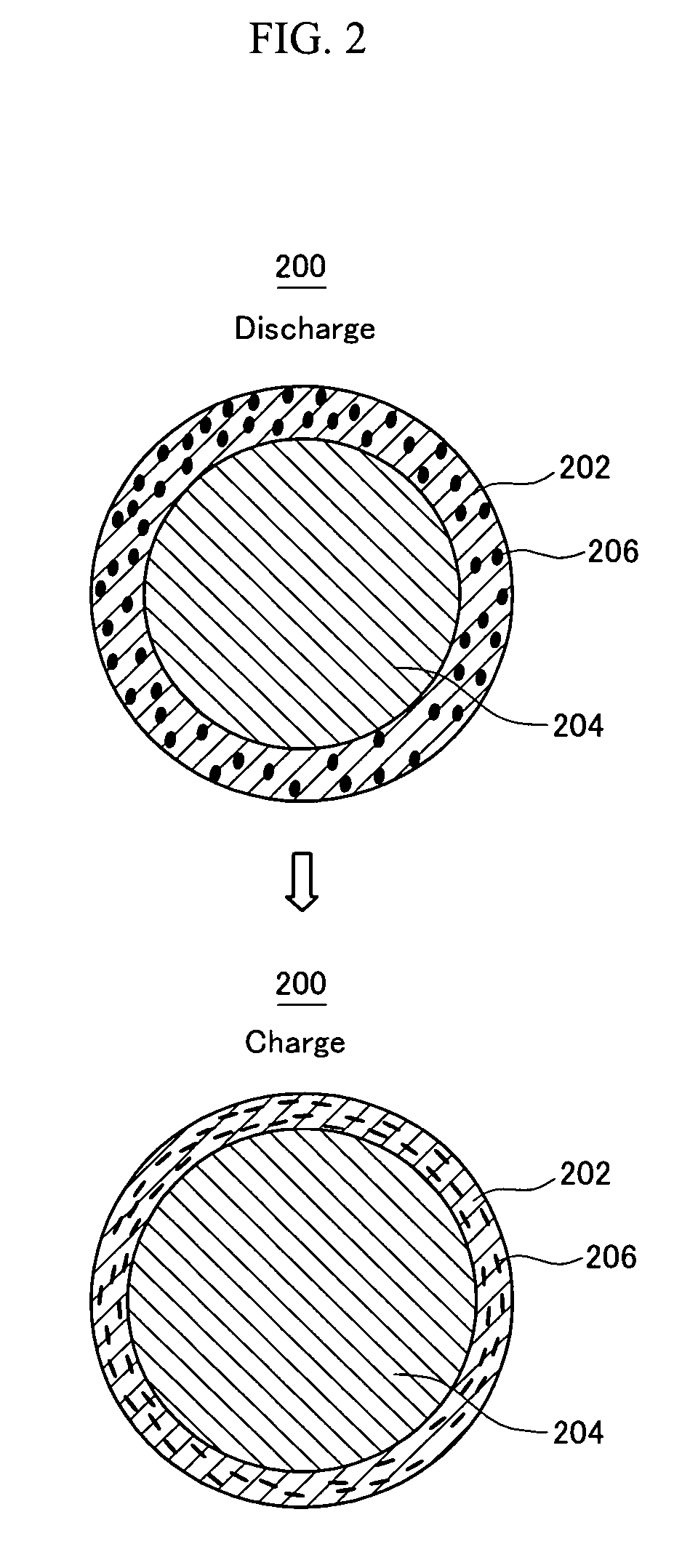

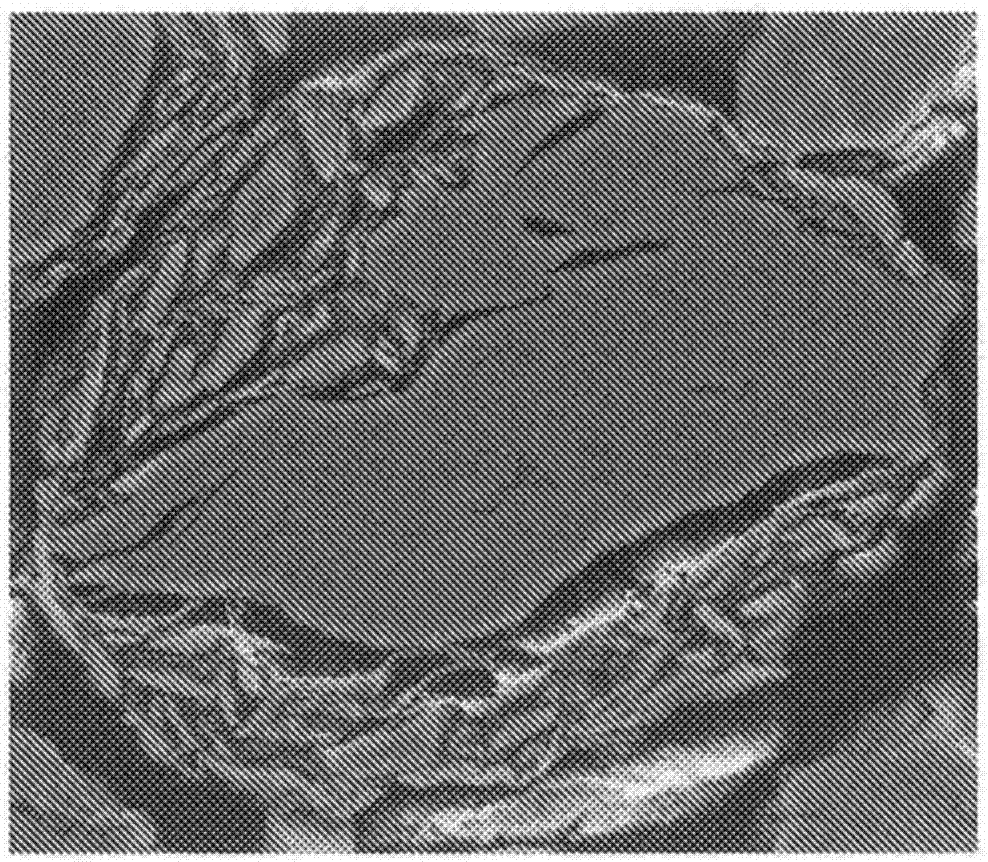

Negative active material for a rechargeable lithium battery, a method of preparing the same, and a rechargeable lithium battery comprising the same

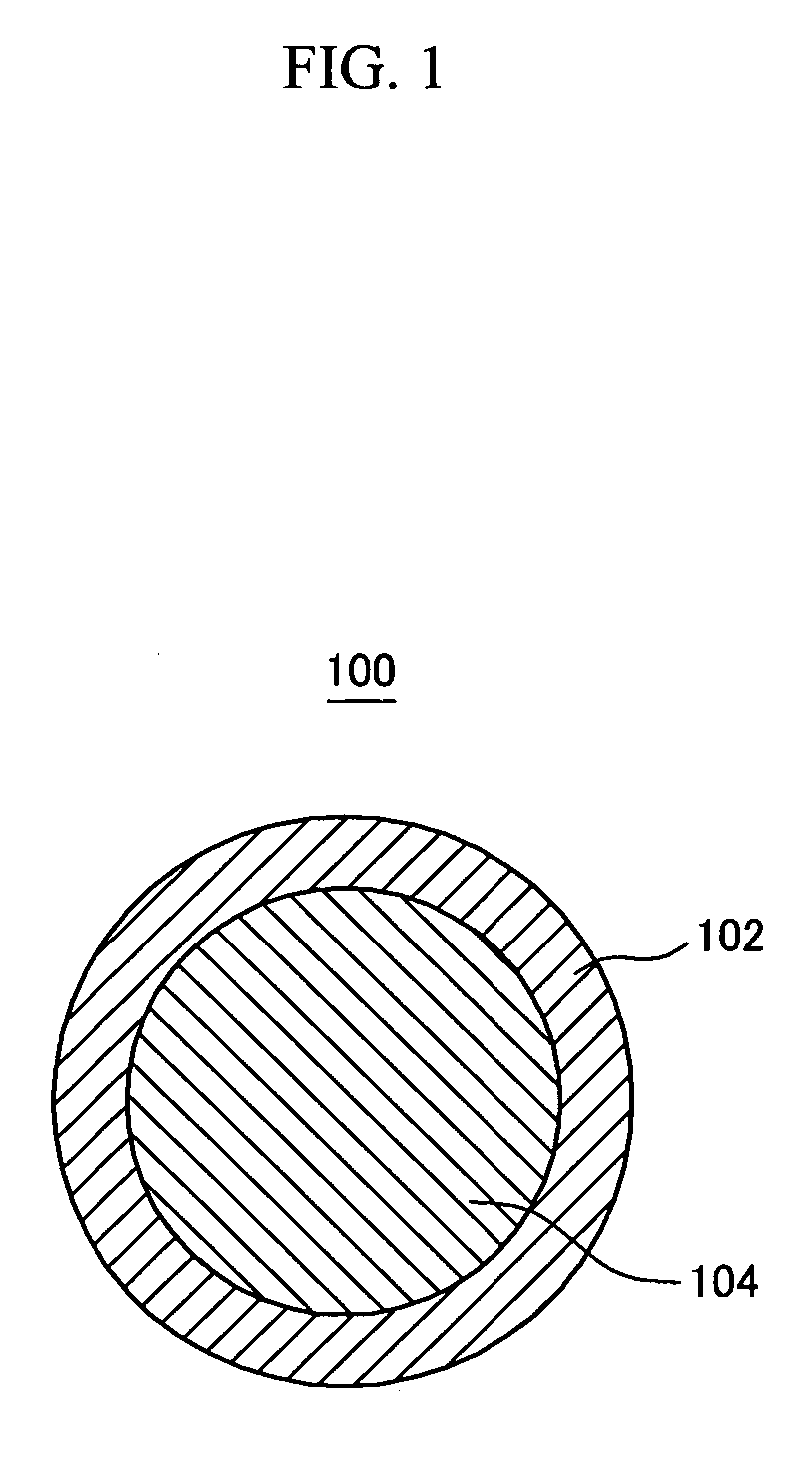

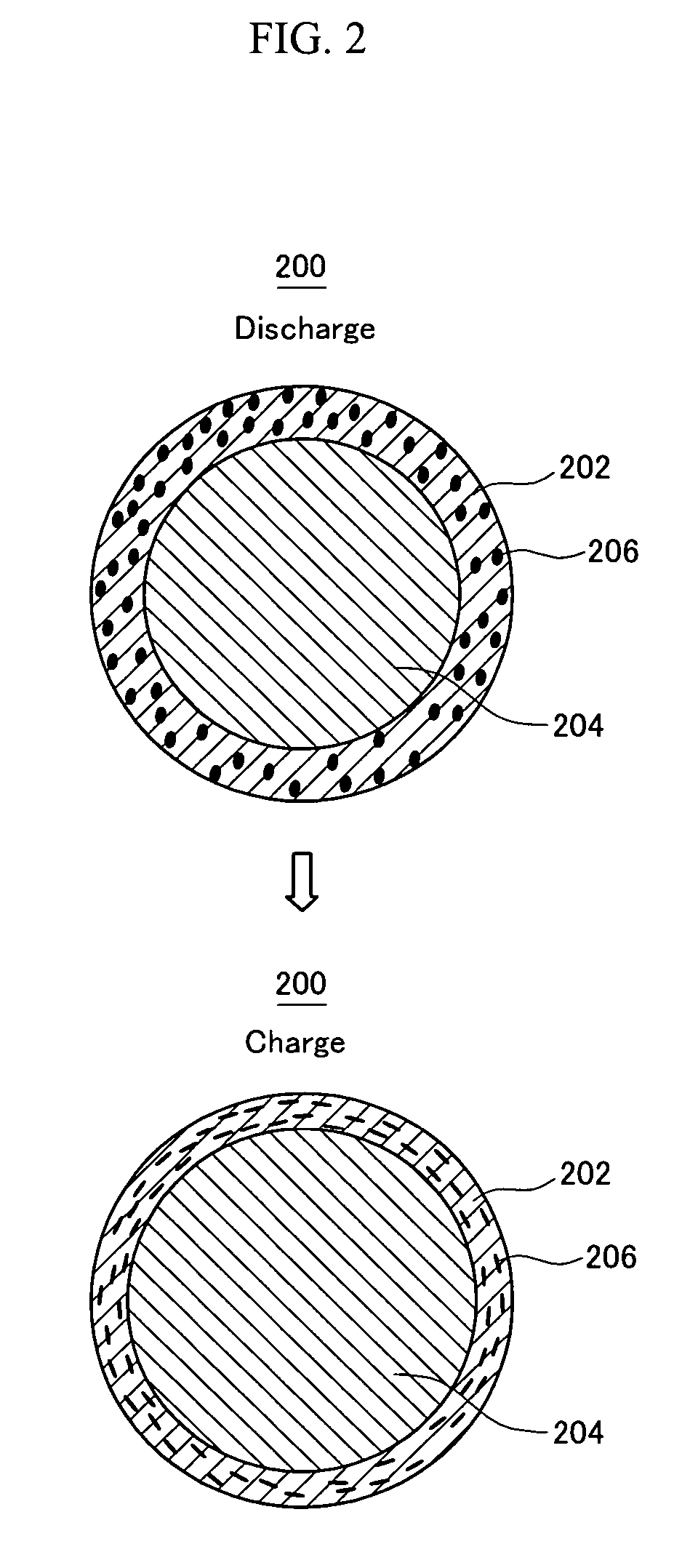

ActiveUS20070122712A1Improved cycle life characteristicsImprove featuresElectrode manufacturing processesSecondary cellsMaterials scienceCarbon substrate

Negative active materials for rechargeable lithium batteries, methods of manufacturing the negative active materials, and rechargeable lithium batteries including the negative active materials are provided. One negative active material includes an active metal core and a crack inhibiting layer formed on the core. The crack inhibiting layer includes a carbon-based material.

Owner:SAMSUNG SDI CO LTD

Positive electrode for nonaqueous electrolyte secondary battery, and production method thereof

InactiveUS7981544B2Good effectWasted spaceFinal product manufactureActive material electrodesManganese oxideCobalt

A positive electrode for a nonaqueous electrolyte secondary battery using a positive electrode active material mixture according to an embodiment of the invention includes a positive electrode active material capable of intercalating and deintercalating a lithium ion, a conductive agent and a binder, in which the positive electrode active material is produced by coating cobalt-based lithium composite oxide represented by a general formula: LiaCo1-sM1sO2 with lithium nickel cobalt manganese oxide represented by a general formula: LibNitCouMnvO2, the ratio r1 / r2 of the average particle diameter r1 of the cobalt-based lithium composite oxide and the average particle diameter r2 of the lithium nickel cobalt manganese oxide is 2≦r1 / r2≦50, and the average particle diameter r2 of the lithium nickel cobalt manganese oxide is 0.5 μm≦r2≦20 μm. By containing such a constitution, a positive electrode for a nonaqueous electrolyte secondary battery in which even when the charging discharging is repeated at a high potential of 4.5 V based on lithium, not only is the retention characteristics in a charged state excellent, but also the enhancing the capacity and the energy density of the battery can be achieved; and a production method thereof, can be provided.

Owner:SANYO ELECTRIC CO LTD

Negative active material for rechargeable lithium battery, and method of preparing the same

InactiveUS20090136847A1High initial capacityImprove initial efficiencyMaterial nanotechnologyActive material electrodesMaterials scienceLithium battery

A negative active material for a rechargeable lithium battery with a composite phase particle has a chemical formula, SiOx, where 0<x<1. The material comprises a first crystalline phase of Si nano-grains, and a second phase of non-crystalline SiO2, where the composite phase particle has a Si-phase peak of 150 to 480 cm−1 according to Raman spectroscopic analysis.

Owner:SAMSUNG SDI CO LTD +1

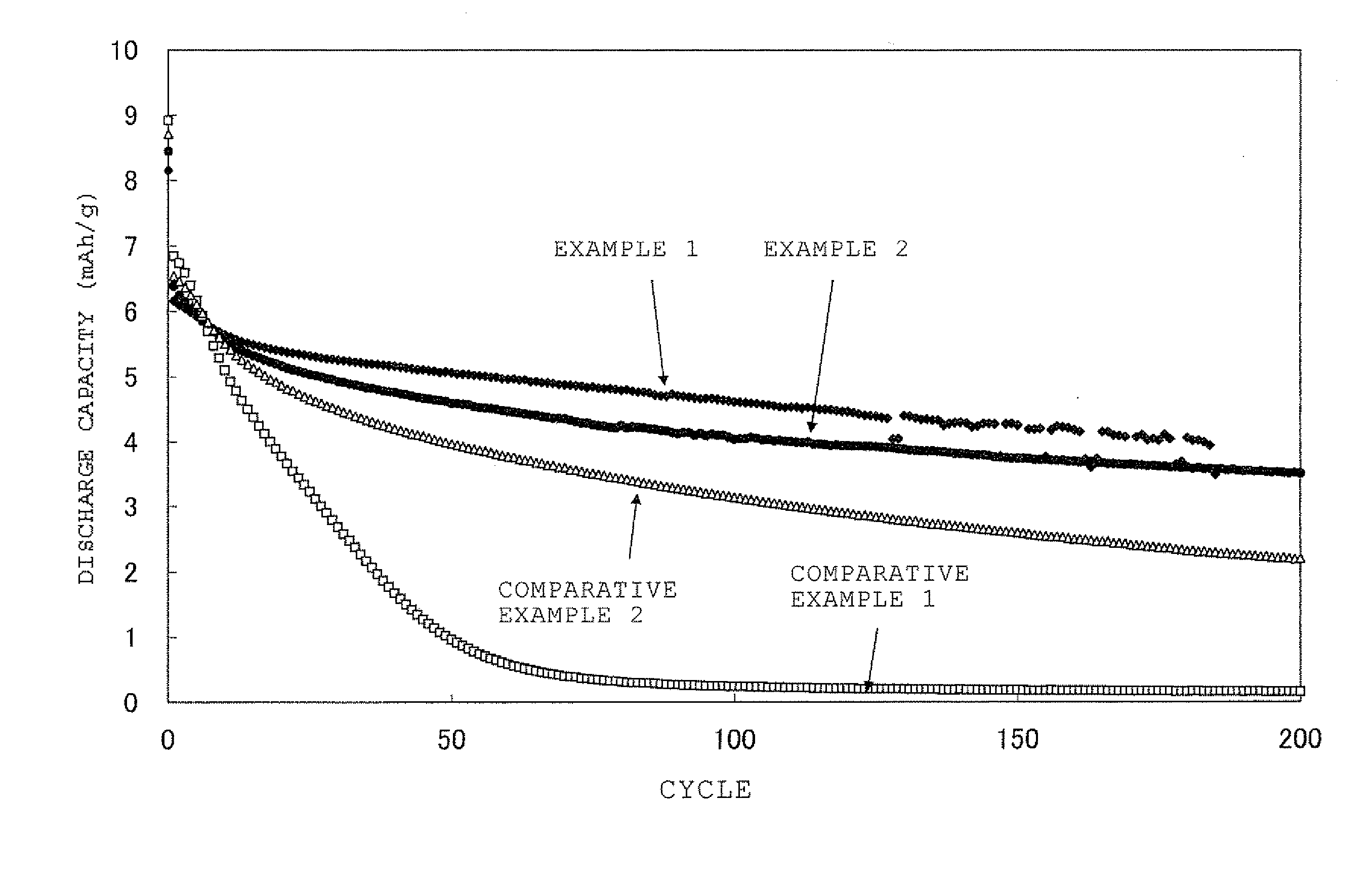

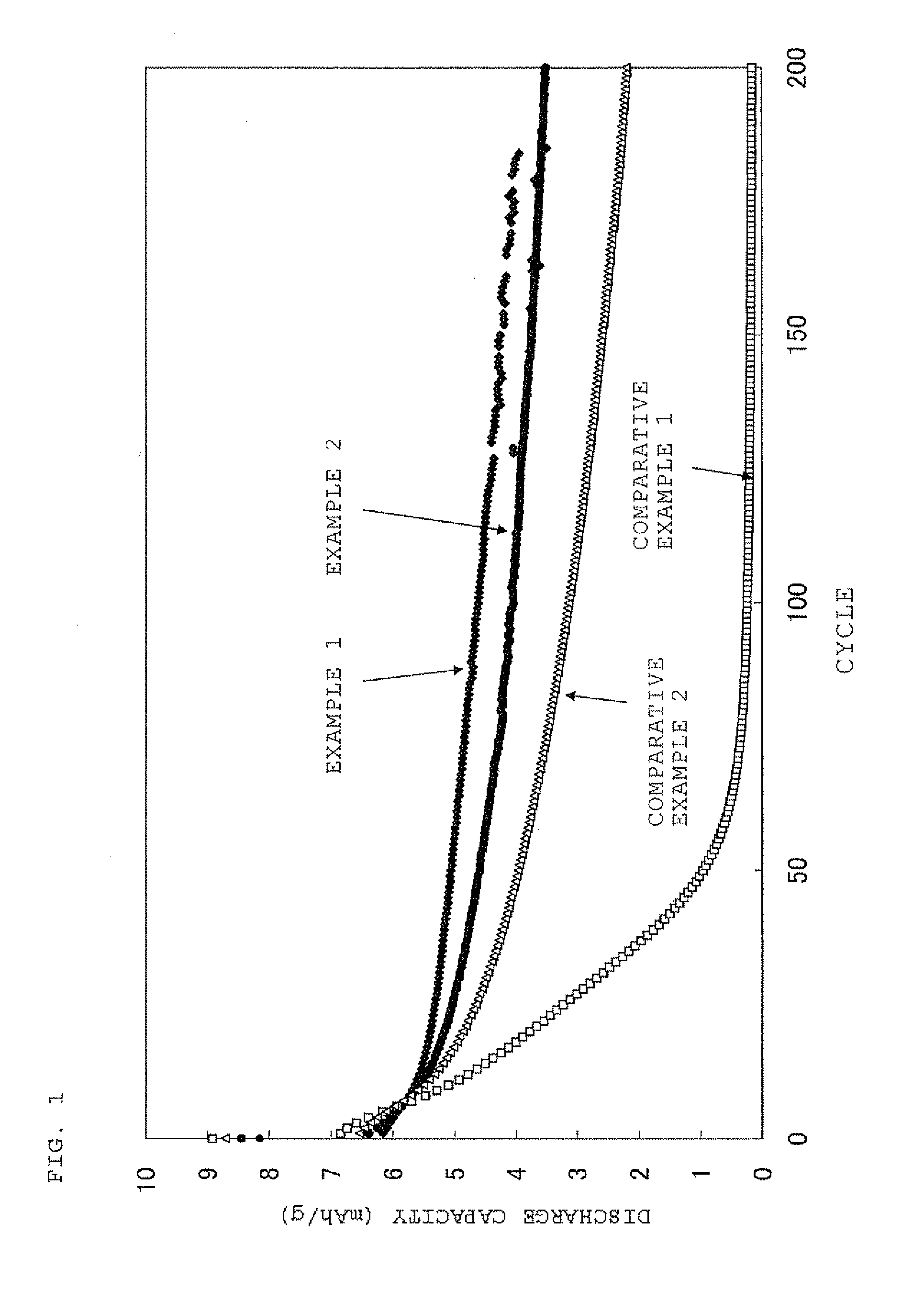

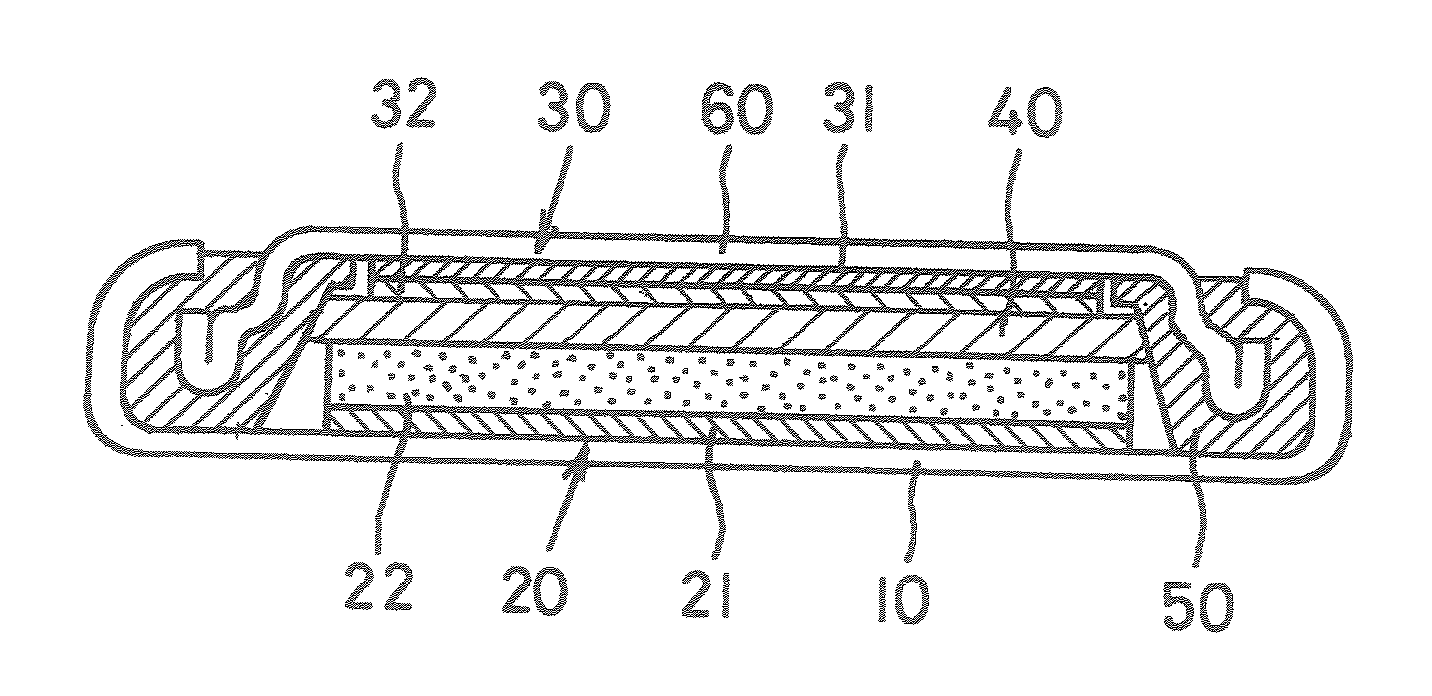

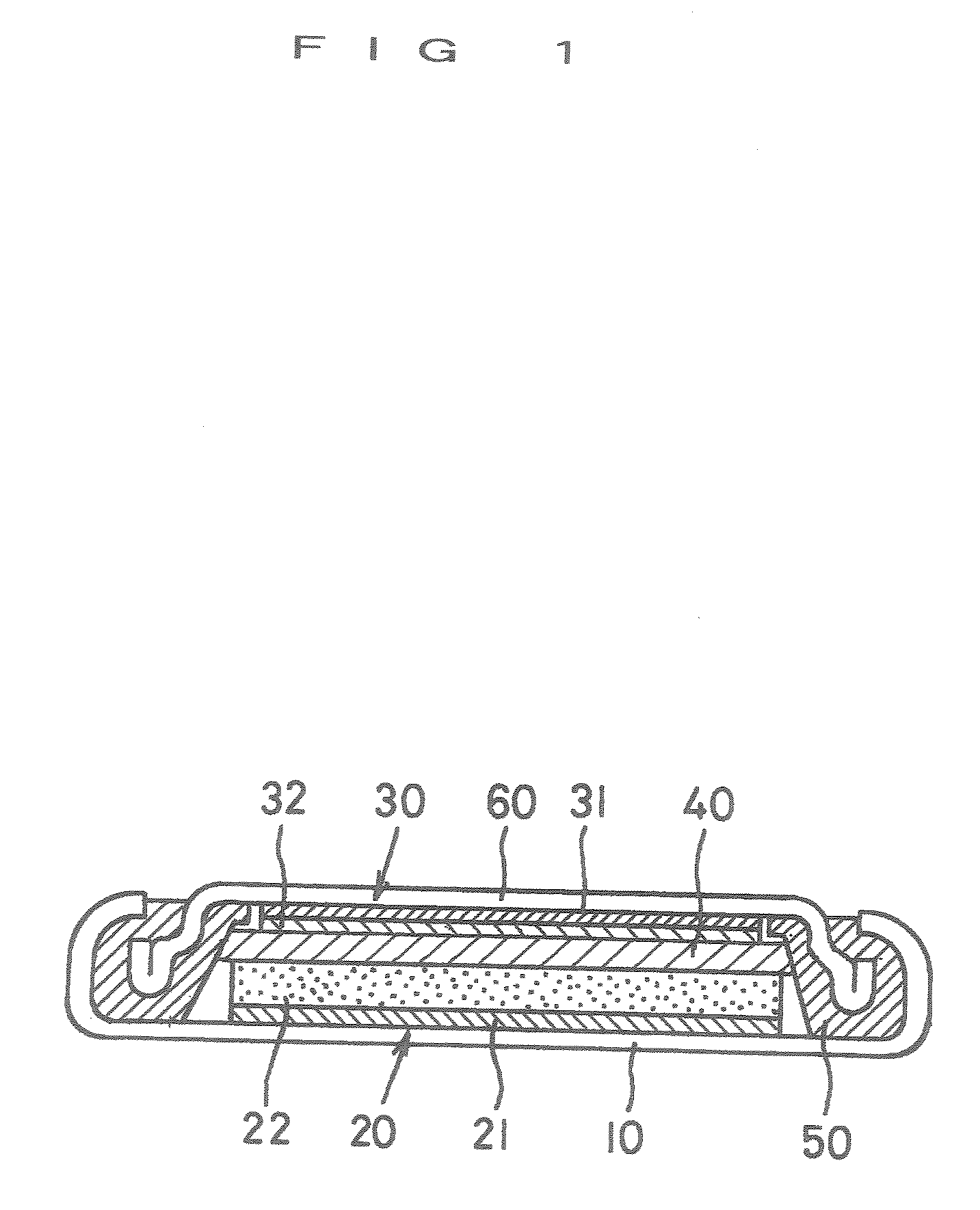

Non-aqueous electrolyte secondary battery, negative electrode material, and making method

ActiveCN101567438ASmall volume expansionImprove initial efficiencyElectrode manufacturing processesSiliconSilicon oxideSilicon particle

A negative electrode material comprising an active material and 1-20 wt% of a polyimide resin binder is suitable for use in non-aqueous electrolyte secondary batteries. The active material comprises silicon oxide particles and 1-50 wt% of silicon particles. The negative electrode exhibits improved cycle performance while maintaining the high battery capacity and low volume expansion of silicon oxide. The non-aqueous electrolyte secondary battery has a high initial efficiency and maintains improved performance and efficiency over repeated charge / discharge cycles by virtue of mitigated volumetric changes during charge / discharge cycles.

Owner:SHIN ETSU CHEM IND CO LTD

Method for manufacturing negative electrode active material for non-aqueous electrolyte secondary battery, negative electrode active material for non-aqueous electrolyte secondary battery, negative electrode material for non-aqueous electrolyte secondary battery, negative electrode for non-aqueous electrolyte secondary battery, and non-aqueous electrolyte secondary battery

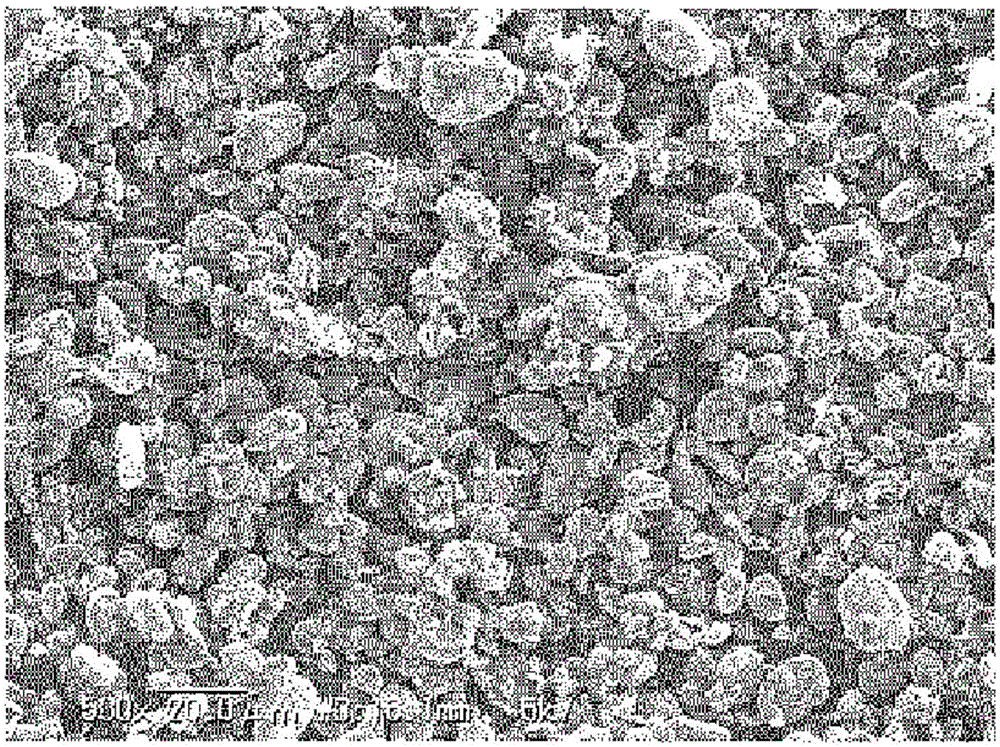

ActiveUS20110287317A1Reduce capacitySmall overall deformationSiliconElectrode thermal treatmentGas phaseElectrical battery

The present invention is a method for manufacturing a negative electrode active material for a non-aqueous electrolyte secondary battery comprising at least depositing silicon on a substrate by vapor deposition by using a metallic silicon as a raw material, the substrate having a temperature controlled to 300° C. to 800° C. under reduced pressure, and pulverizing and classifying the deposited silicon. As a result, there is provided a method for manufacturing a negative electrode active material composed of silicon particles that is an active material useful as a negative electrode of a non-aqueous electrolyte secondary battery in which high initial efficiency and high battery capacity of silicon are kept, cycle performance is superior, and an amount of a change in volume decreases at the time of charge and discharge.

Owner:SHIN ETSU CHEM IND CO LTD

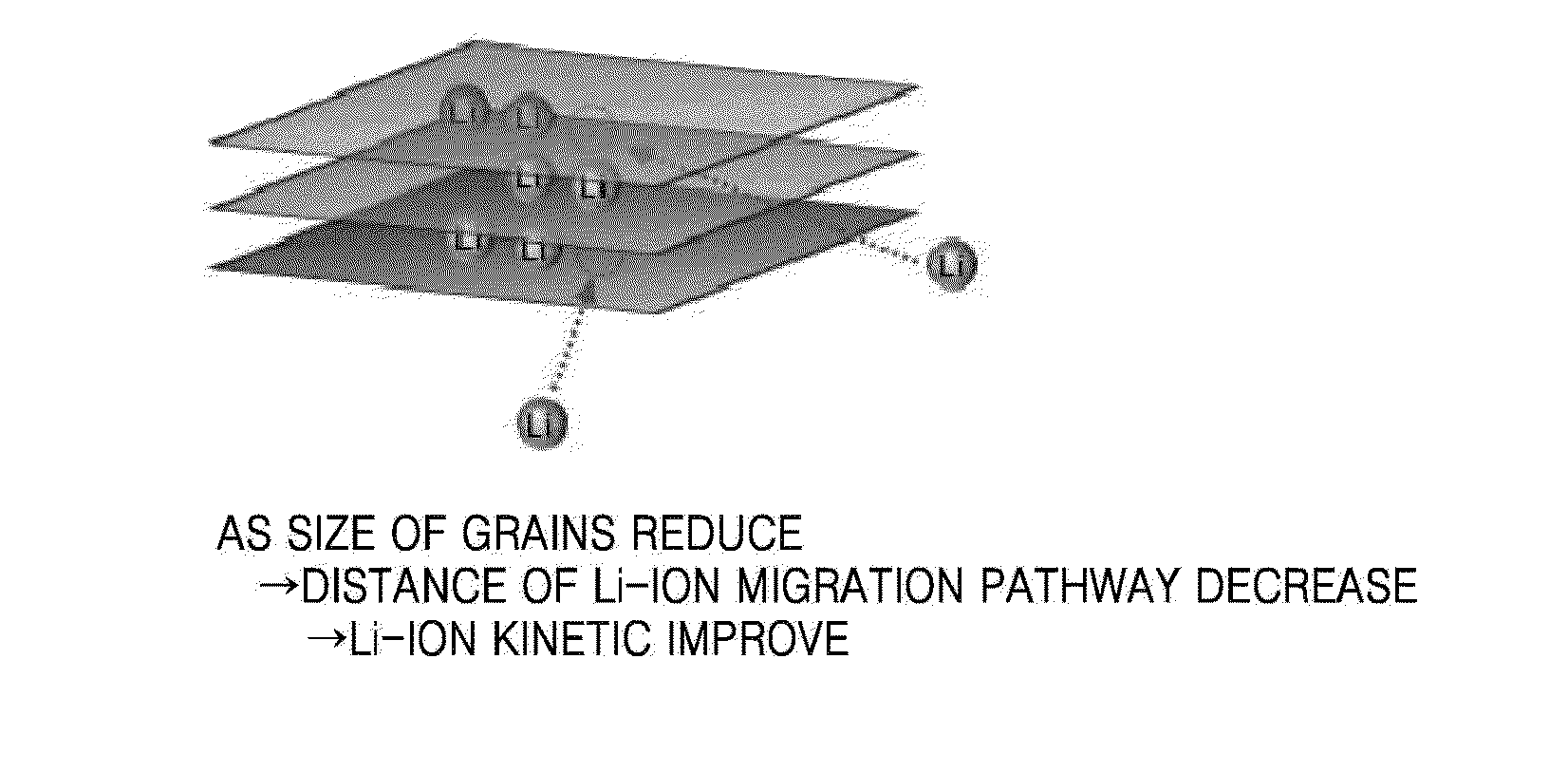

Negative electrode material for lithium ion secondary battery, composite negative electrode material for lithium ion secondary battery, resin composition for lithium ion secondary battery negative electrode for lithium ion secondary battery, and lithium ion secondary battery

ActiveUS20150325848A1High capacity retentionImprove initial efficiencyNegative electrodesSecondary cellsLithiumPhysical chemistry

The present invention provides a negative electrode material for a lithium ion secondary battery, a composite negative electrode material for a lithium ion secondary battery, a resin composition for a lithium ion secondary battery negative electrode, and a negative electrode for a lithium ion secondary electrode, which may provide high charge / discharge capacity, and excellent initial charge-discharge characteristics and capacity retention. The surfaces of core particles of silicon of 5 nm or more and 100 nm or less in average particle size are coated with a coating layer to use a negative electrode material containing substantially no silicon oxide in the coating layer, or a composite negative electrode material for a lithium ion secondary battery, which includes the negative electrode material and a matrix material, further with the use of a polyimide resin or a precursor thereof as a bonding resin, thereby making it possible to achieve high charge / discharge capacity and excellent capacity retention, as well as high initial efficiency.

Owner:TORAY IND INC

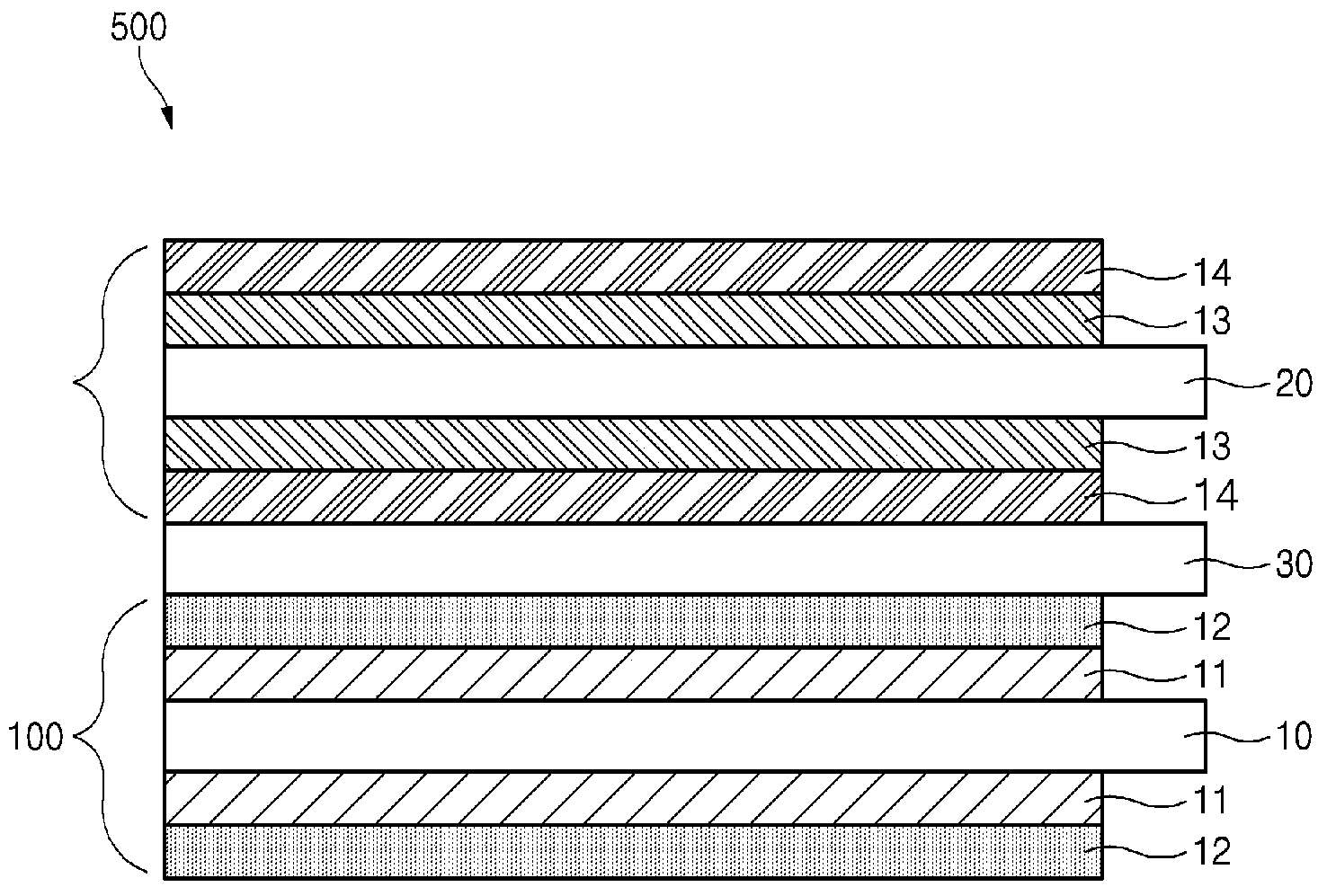

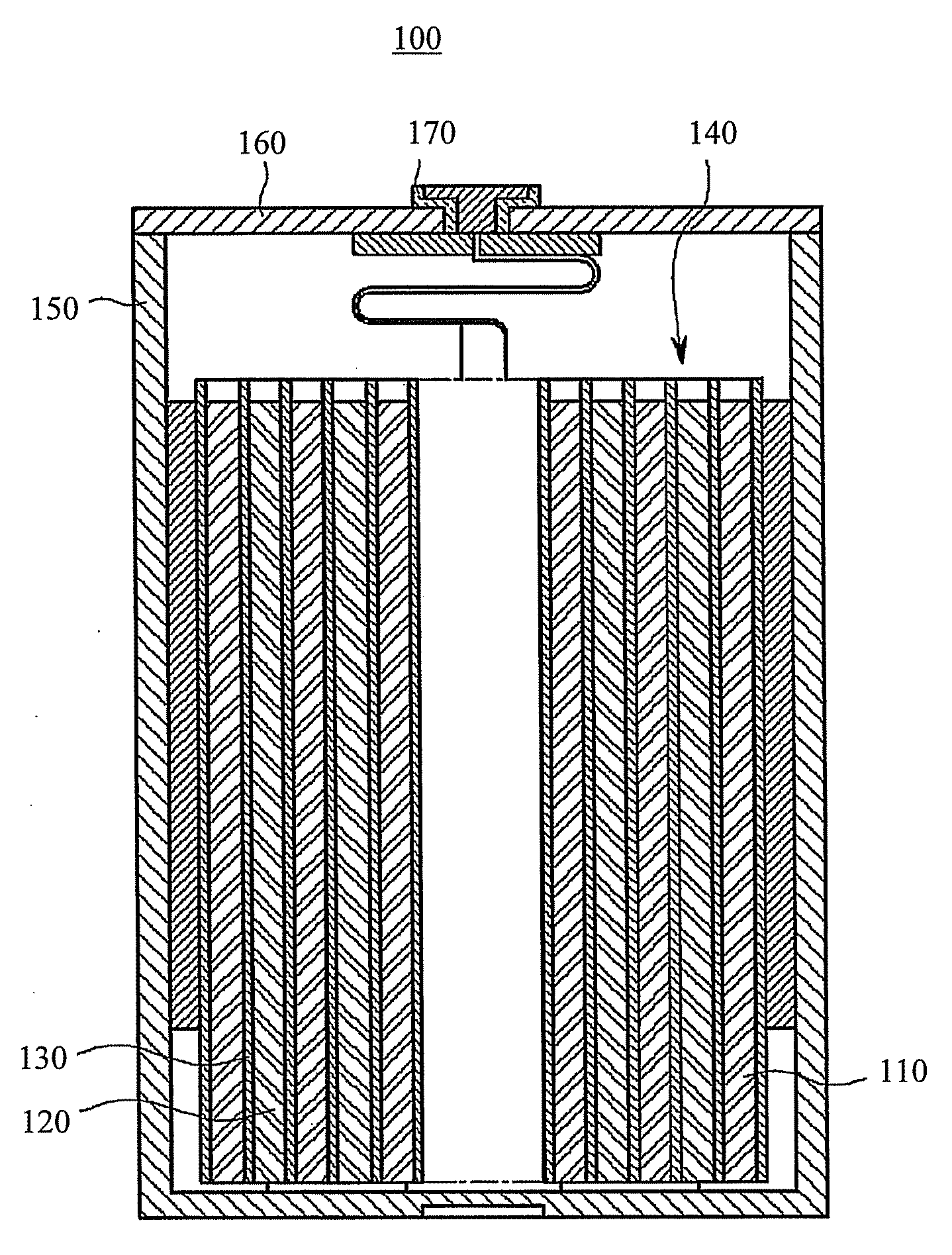

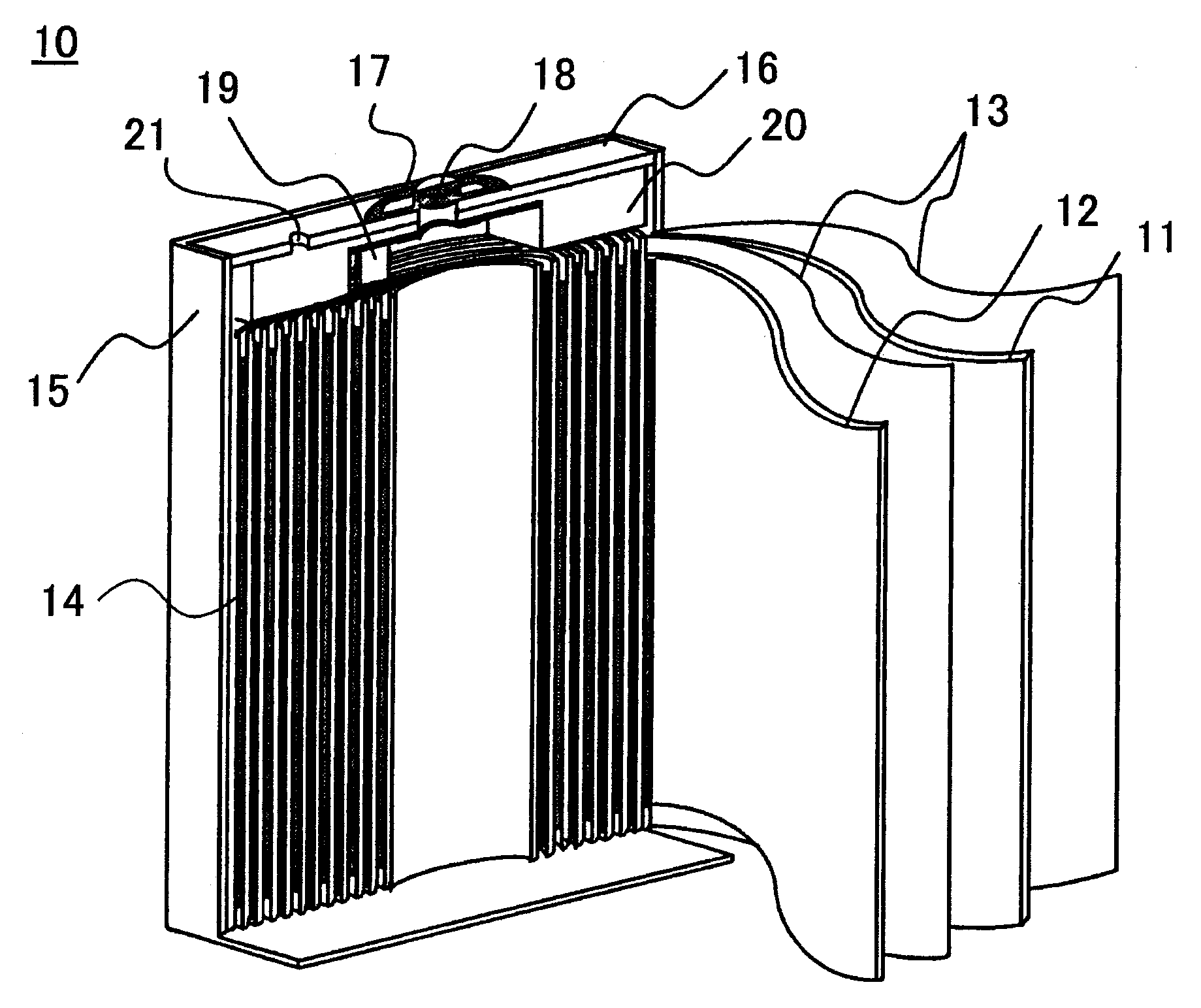

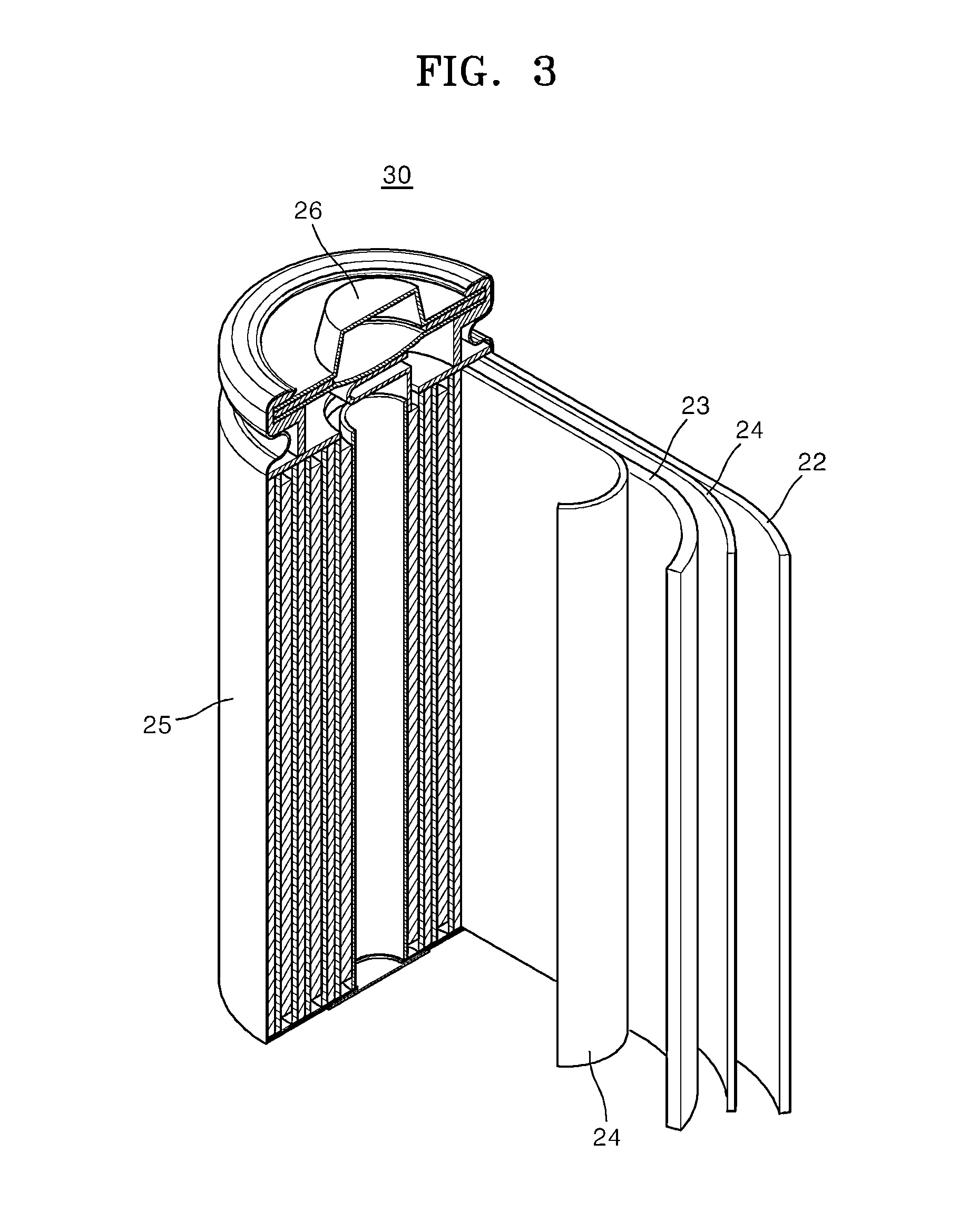

Lithium secondary battery comprising multilayered active material layer

ActiveCN104321912AIncrease powerImprove power characteristicsNon-aqueous electrolyte accumulator electrodesLi-accumulatorsLithiumEngineering

A lithium secondary battery of the present invention may simultaneously improve high output and high capacity characteristics by including a first active material layer having high output characteristics and a second active material layer having high capacity characteristics respectively on a cathode collector and an anode collector.

Owner:LG ENERGY SOLUTION LTD

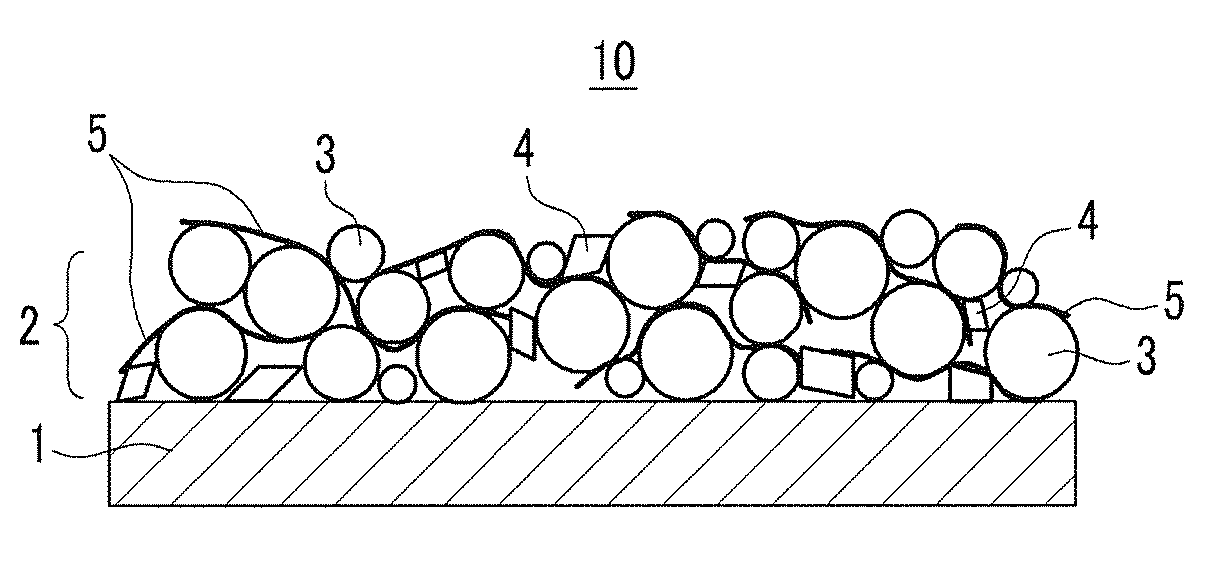

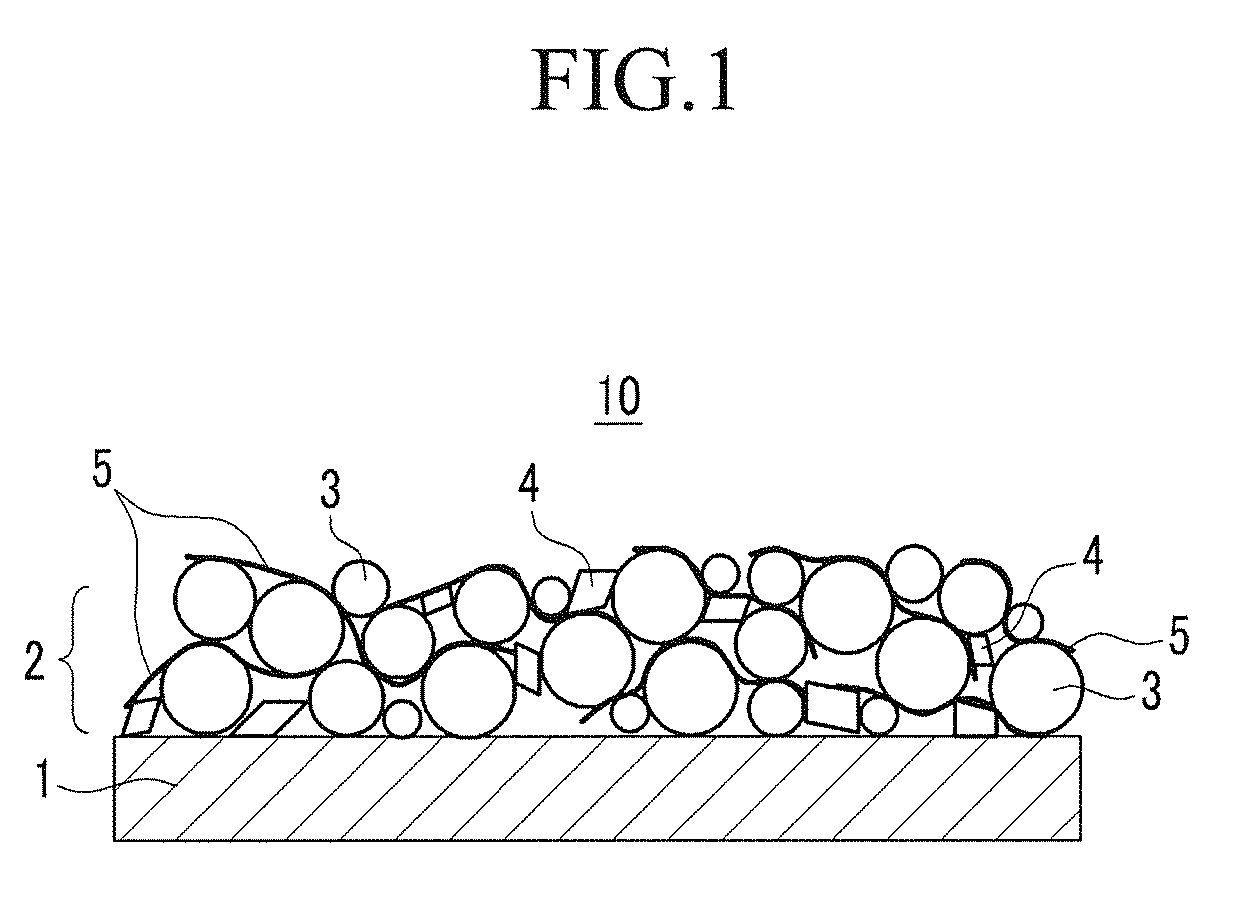

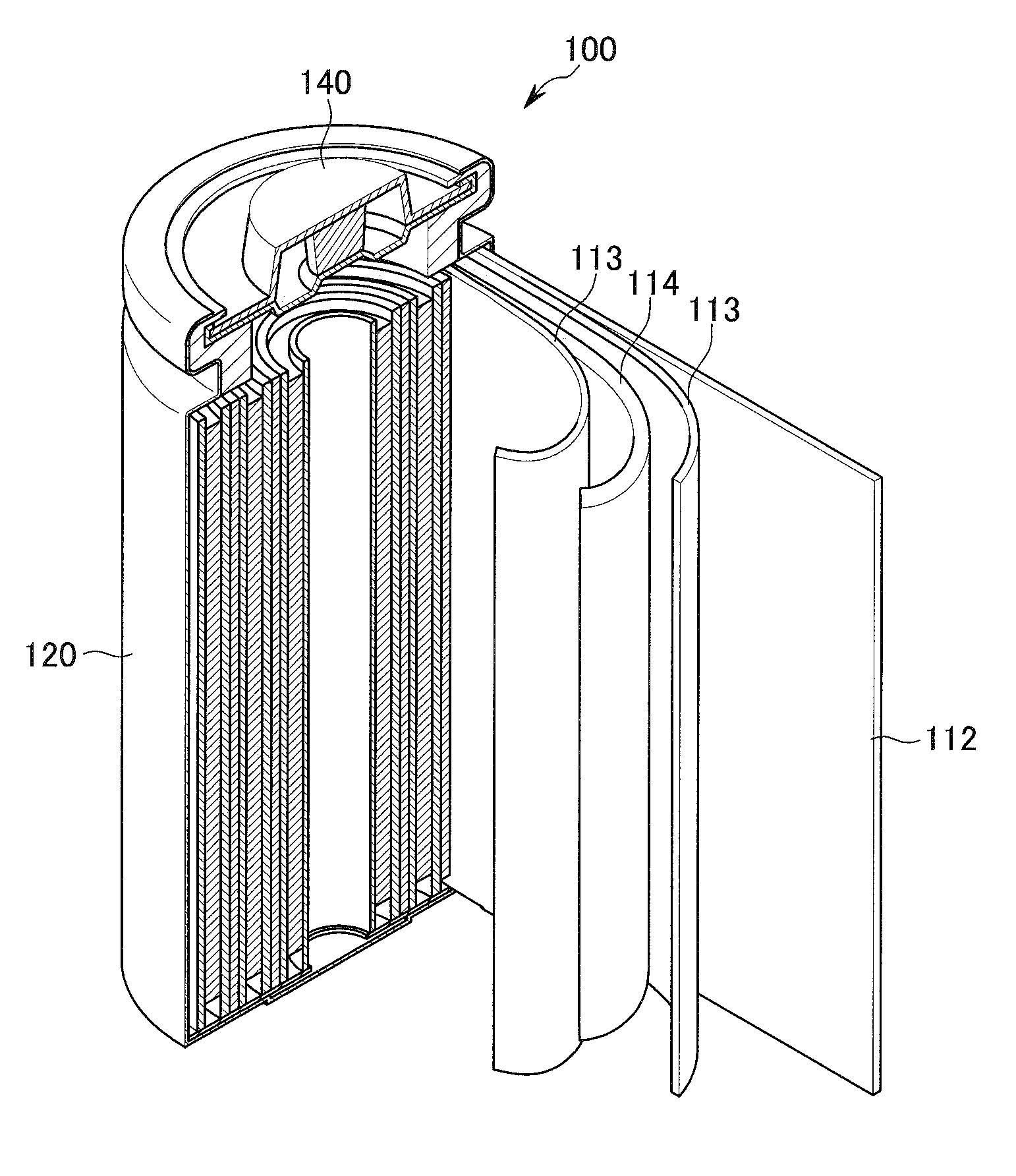

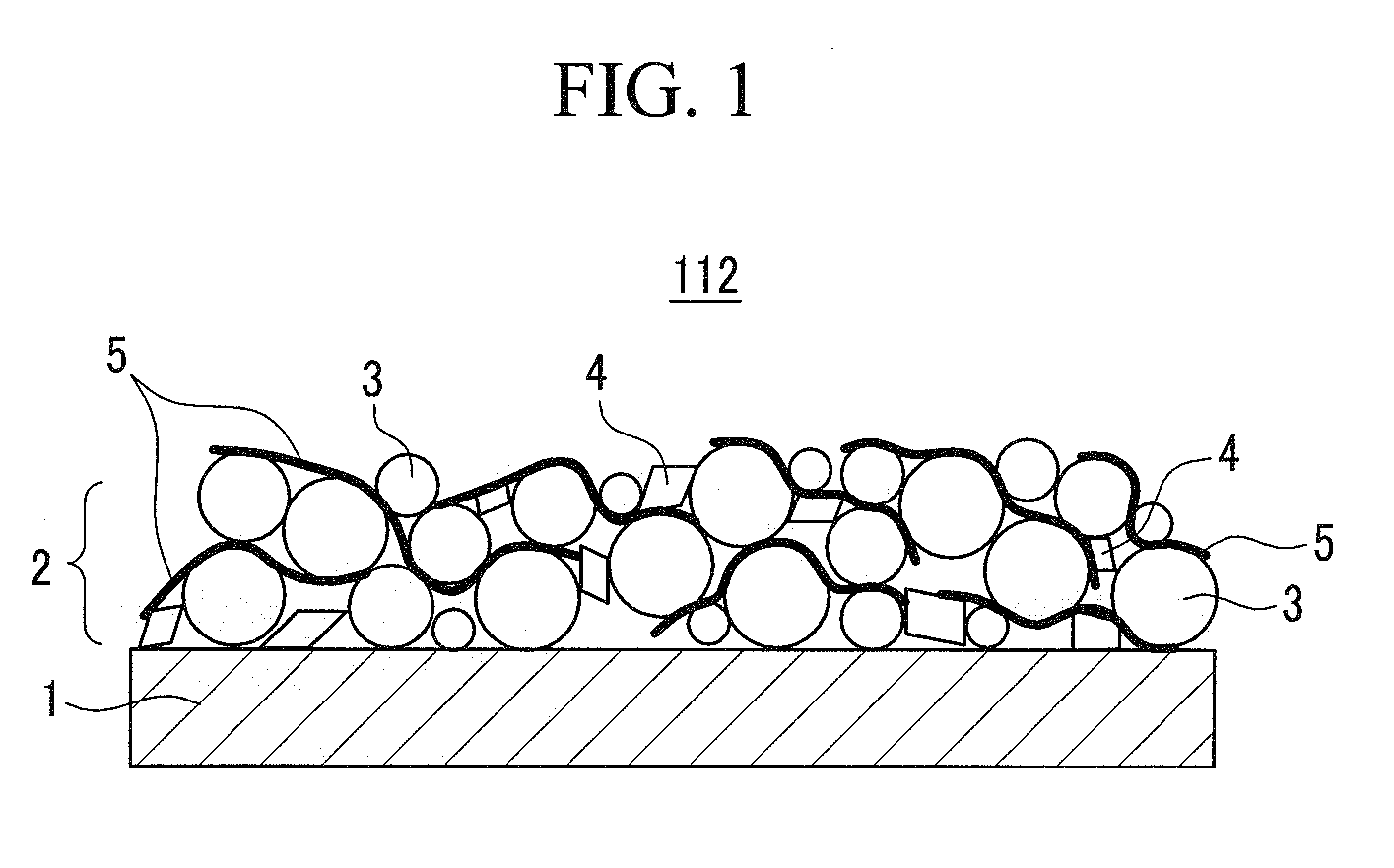

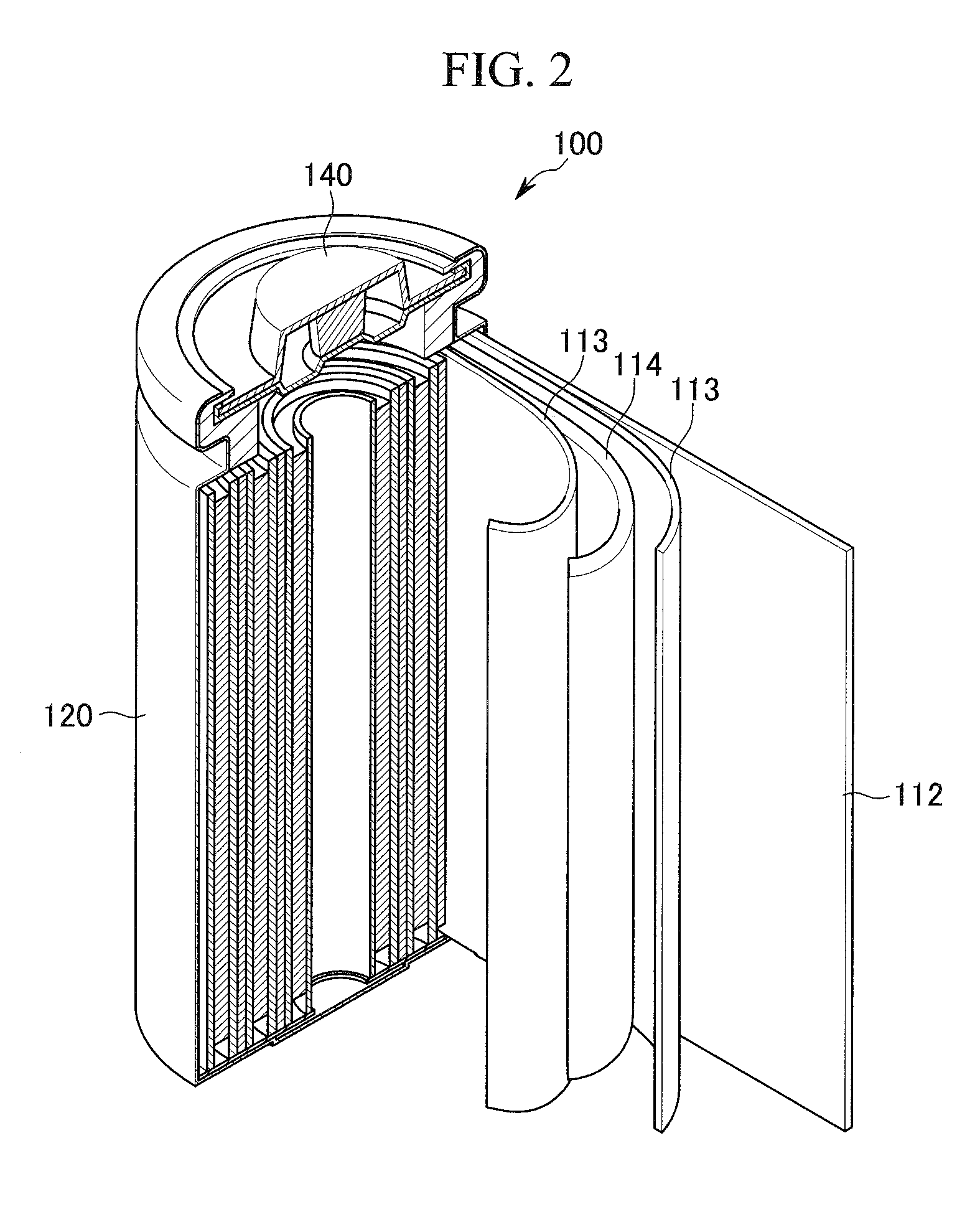

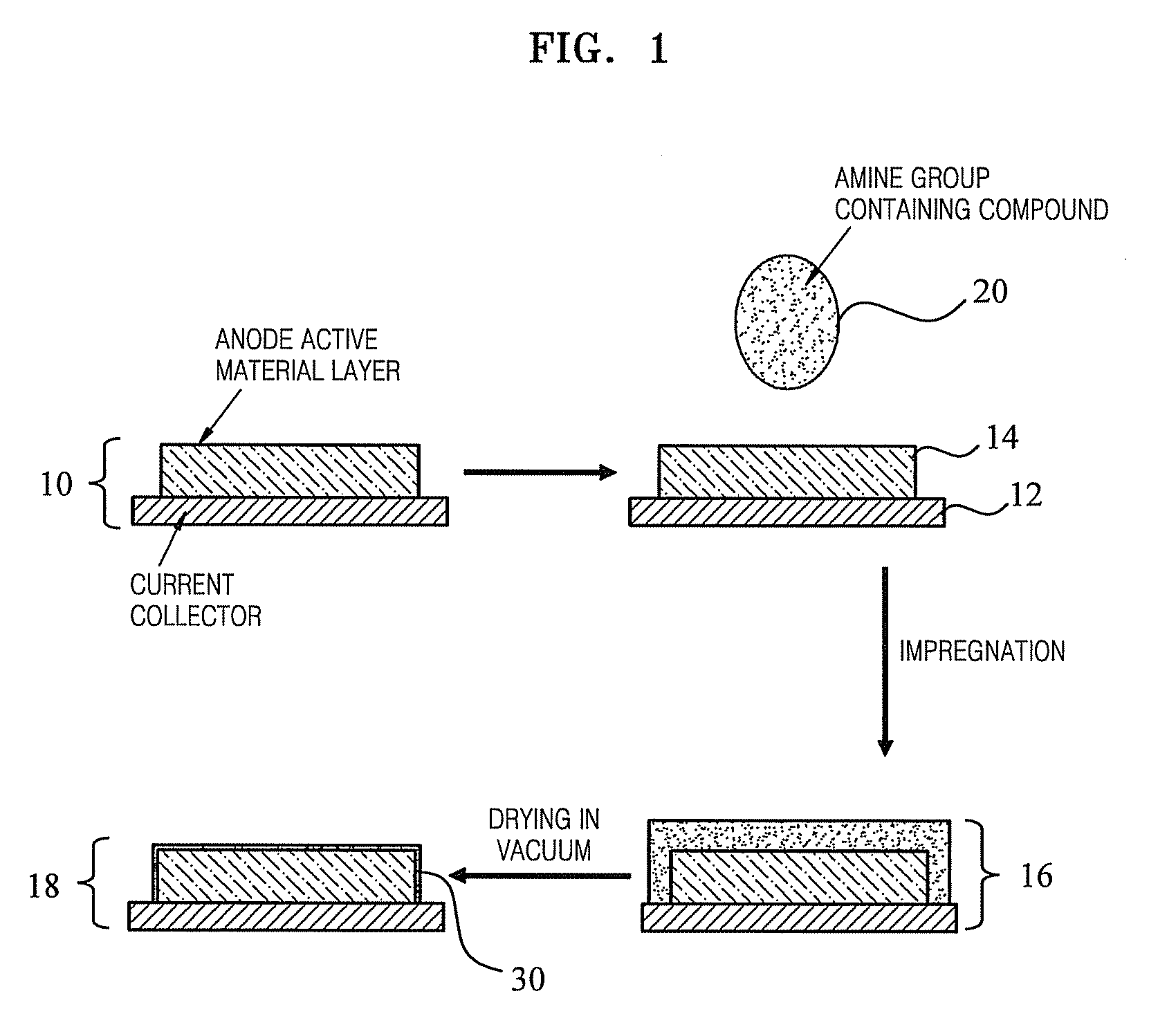

Surface treated anode and lithium battery using the same

InactiveUS20090053606A1Improve initial efficiencyExcellent cycle characteristicsConductive materialElectrode carriers/collectorsCurrent collectorOptoelectronics

A surface treated anode and a lithium battery using the same are provided. The surface treated anode includes a current collector, and an anode active material layer formed on the current collector. The anode active material layer is treated with an amine group containing compound.

Owner:SAMSUNG SDI CO LTD

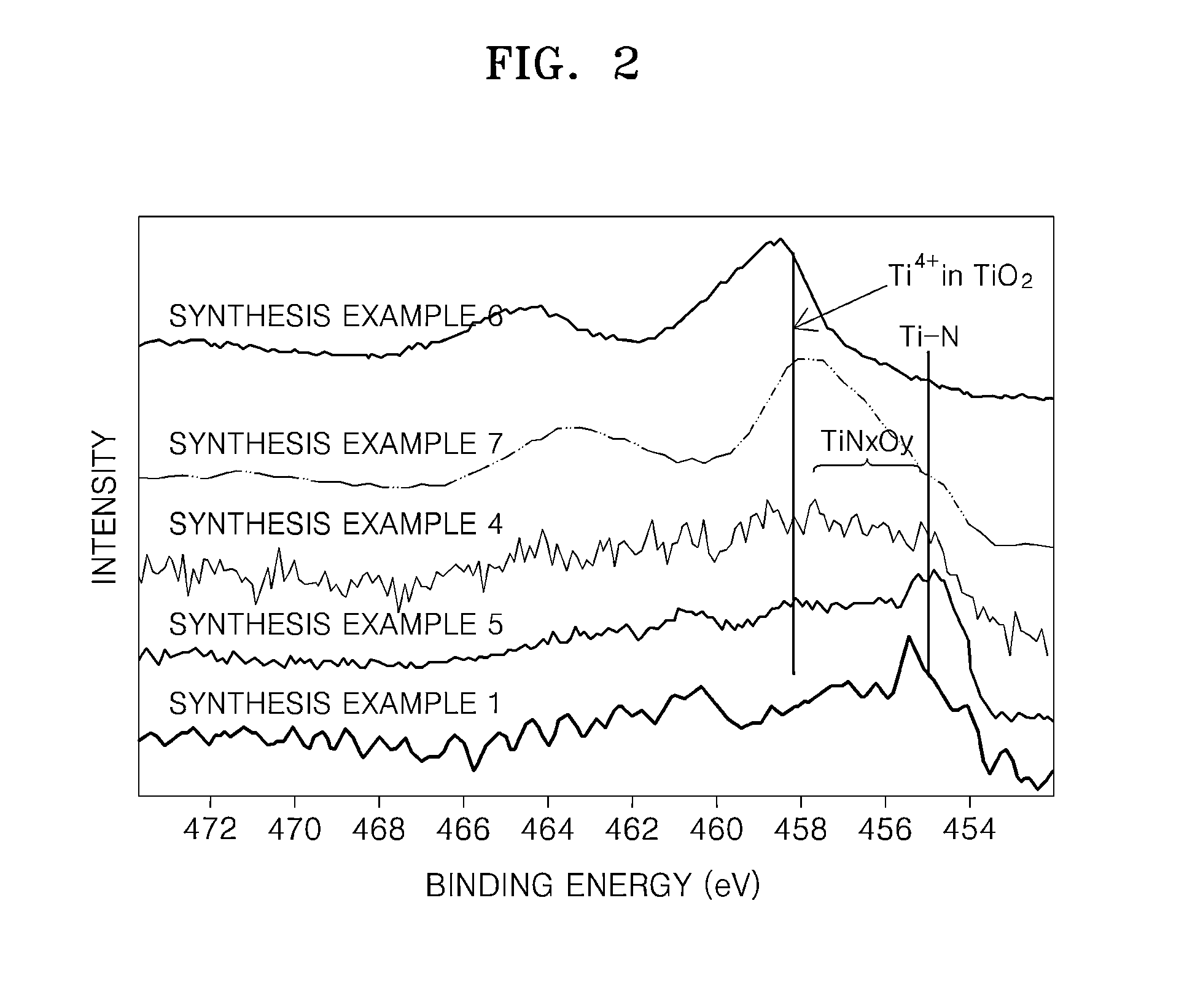

Anode active material for lithium rechargeable battery, method of preparing the same, and lithium battery including the anode active material

ActiveUS20130143119A1Improve initial efficiencyExcellent lifespan characteristicNon-metal conductorsFinal product manufactureNitrideMaterials science

Owner:SAMSUNG ELECTRONICS CO LTD

Negative active material for a rechargeable lithium battery, a method of preparing the same, and a rechargeable lithium battery comprising the same

ActiveUS8394532B2Improve featuresImprove initial efficiencyElectrode manufacturing processesNegative electrodesMetalMaterials science

Negative active materials for rechargeable lithium batteries, methods of manufacturing the negative active materials, and rechargeable lithium batteries including the negative active materials are provided. One negative active material includes an active metal core and a crack inhibiting layer formed on the core. The crack inhibiting layer includes a carbon-based material.

Owner:SAMSUNG SDI CO LTD

Positive active material, method of preparing the same, and lithium battery including the positive active material

ActiveUS20140106222A1Enhanced Efficiency StabilityImprove high temperature stabilitySilver accumulatorsFinal product manufacturePhysical chemistryLithium battery

Owner:SAMSUNG SDI CO LTD

Positive electrode for nonaqueous electrolyte secondary battery, and production method thereof

InactiveUS20080193846A1Good effectWasted spaceFinal product manufactureActive material electrodesManganese oxideCobalt

A positive electrode for a nonaqueous electrolyte secondary battery using a positive electrode active material mixture according to an embodiment of the invention includes a positive electrode active material capable of intercalating and deintercalating a lithium ion, a conductive agent and a binder, in which the positive electrode active material is produced by coating cobalt-based lithium composite oxide represented by a general formula: LiaCo1-sM1sO2 with lithium nickel cobalt manganese oxide represented by a general formula: LibNitCouMnvO2, the ratio r1 / r2 of the average particle diameter r1 of the cobalt-based lithium composite oxide and the average particle diameter r2 of the lithium nickel cobalt manganese oxide is 2≦r1 / r2≦50, and the average particle diameter r2 of the lithium nickel cobalt manganese oxide is 0.5 μm≦r2≦20 μm. By containing such a constitution, a positive electrode for a nonaqueous electrolyte secondary battery in which even when the charging discharging is repeated at a high potential of 4.5 V based on lithium, not only is the retention characteristics in a charged state excellent, but also the enhancing the capacity and the energy density of the battery can be achieved; and a production method thereof, can be provided.

Owner:SANYO ELECTRIC CO LTD

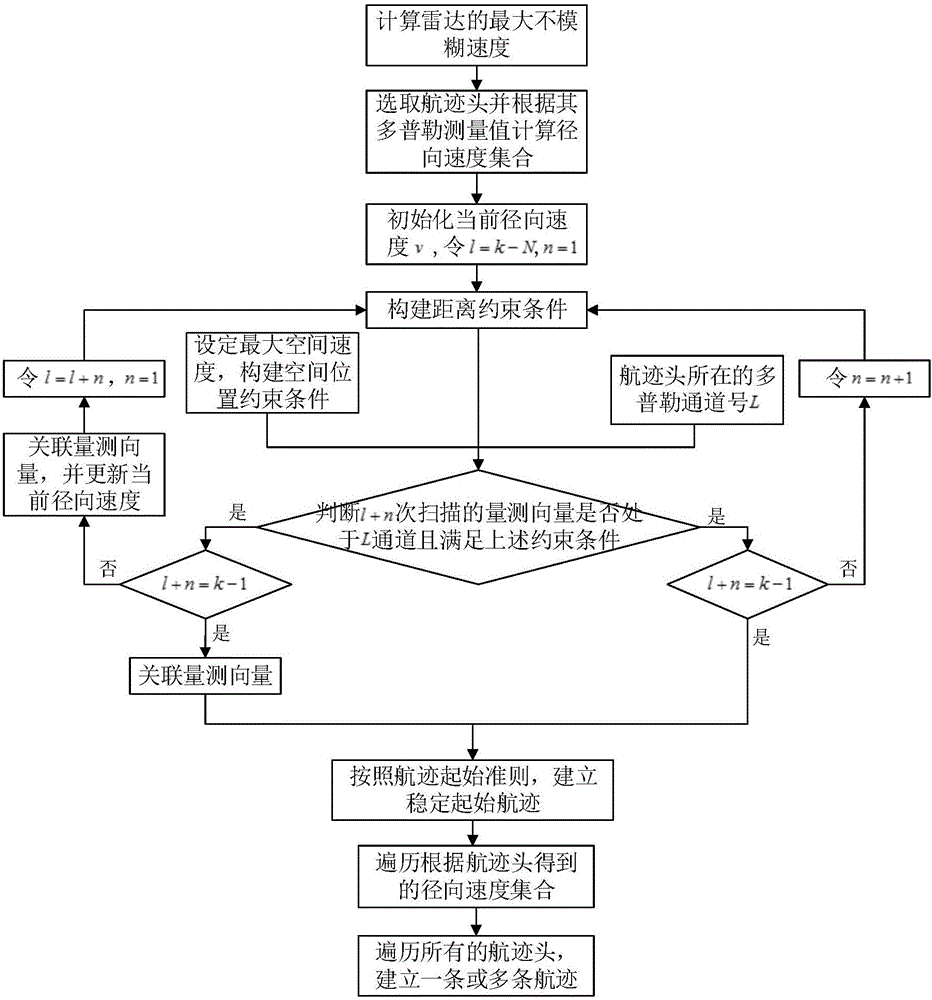

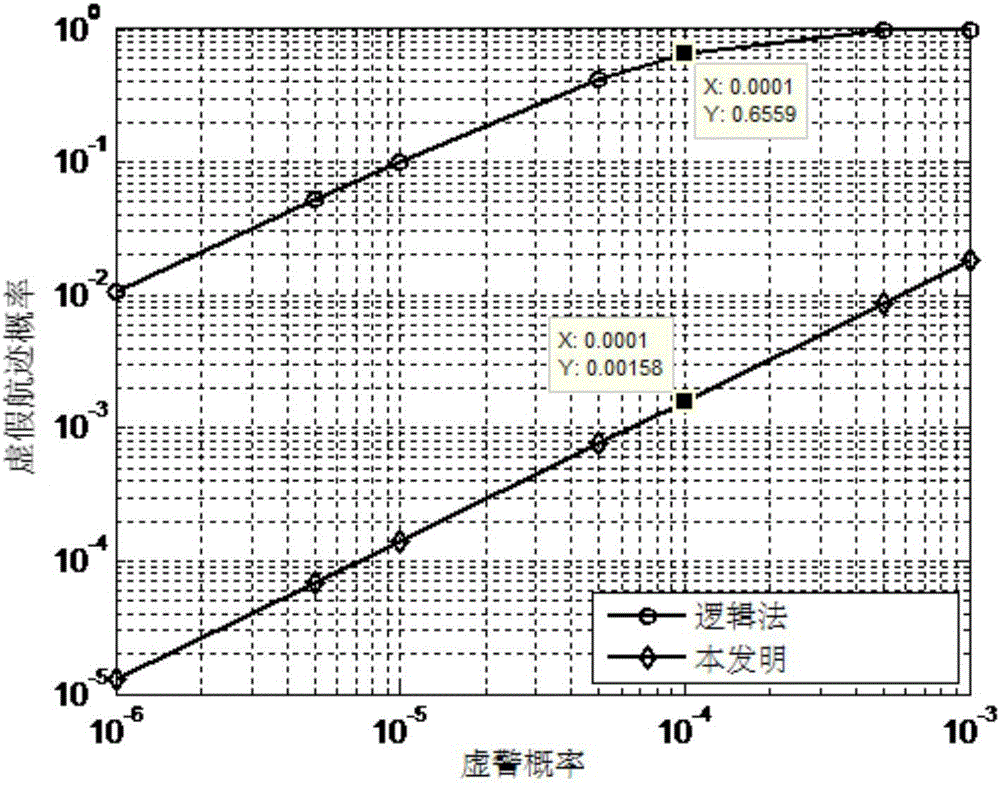

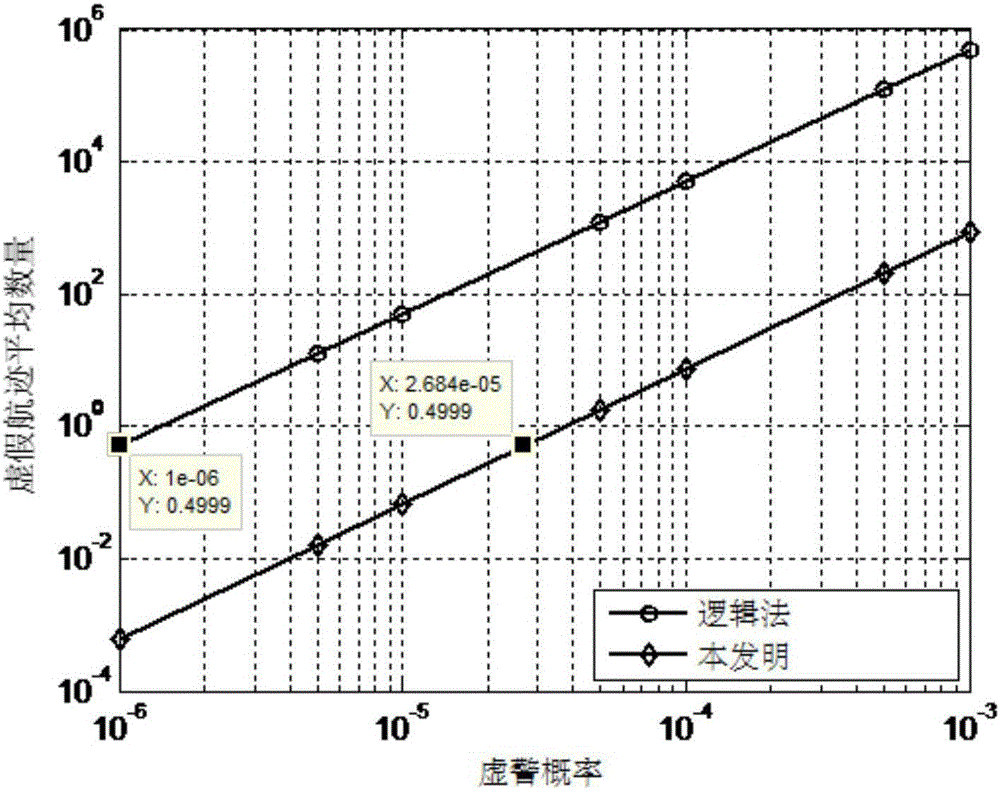

Radar track initiation method based on location information and Doppler information

ActiveCN106405537AAccurate removalIncrease the probability of startingRadio wave reradiation/reflectionRadarDistance constraints

The invention puts forward a radar track initiation method based on location information and Doppler information in order to solve the technical problem that the existing sequential processing technical method is of low track initiation efficiency. The method is implemented by the steps as follows: calculating the maximum unambiguous velocity; selecting a track head from measurement vectors scanned at the kth time, and calculating a radial velocity set; building a distance constraint accord to the radial velocity; building a space constraint according to the maximum velocity; during (k+1)th scanning, associating measurement vectors which are on the same Doppler channel with the track head and meet the two constraints; using effective measurement vectors to update the distance constraint, and continuing the association operation; building a stable track according to the track initiation criterion; and traversing the measurement vectors scanned at the kth time and a corresponding radial velocity set. The method of the invention is of high track initiation efficiency, and can be used in target tracking.

Owner:XIDIAN UNIV

Negative electrode active material for non-aqueous electrolyte secondary cell, negative electrode for non-aqueous electrolyte secondary cell, non-aqueous electrolyte secondary cell, and method for manufacturing negative electrode active material particles

ActiveCN107636868ALarge capacityImprove initial efficiencyNegative electrodesSilicon oxidesCarbon coatingElectrical battery

The present invention provides a negative electrode active material for a non-aqueous electrolyte secondary cell having negative electrode active material particles, the negative electrode active material particles having a silicon compound (SiOx; where 0.5 <= x <= 1.6) containing a Li compound, wherein the negative electrode active material for a non-aqueous electrolyte secondary cell is characterized in that: the silicon compound has a carbon coating formed at least partially thereon; the negative electrode active material particles include a coating comprising a compound having a boron-fluorine bond and / or a compound having a phosphorus-fluorine bond on at least a part of the surface of the silicon compound, the carbon coating, or both; and the negative electrode active material particles contain elemental boron or elemental phosphorus in a range of 10 mass ppm to 10,000 mass ppm in relation to the total amount of the negative electrode active material particles. A negative electrode active material for a non-aqueous electrolyte secondary cell with which it is possible to increase cell capacity and improve cycle characteristics and initial cell efficiency is thereby provided.

Owner:SHIN ETSU CHEM CO LTD

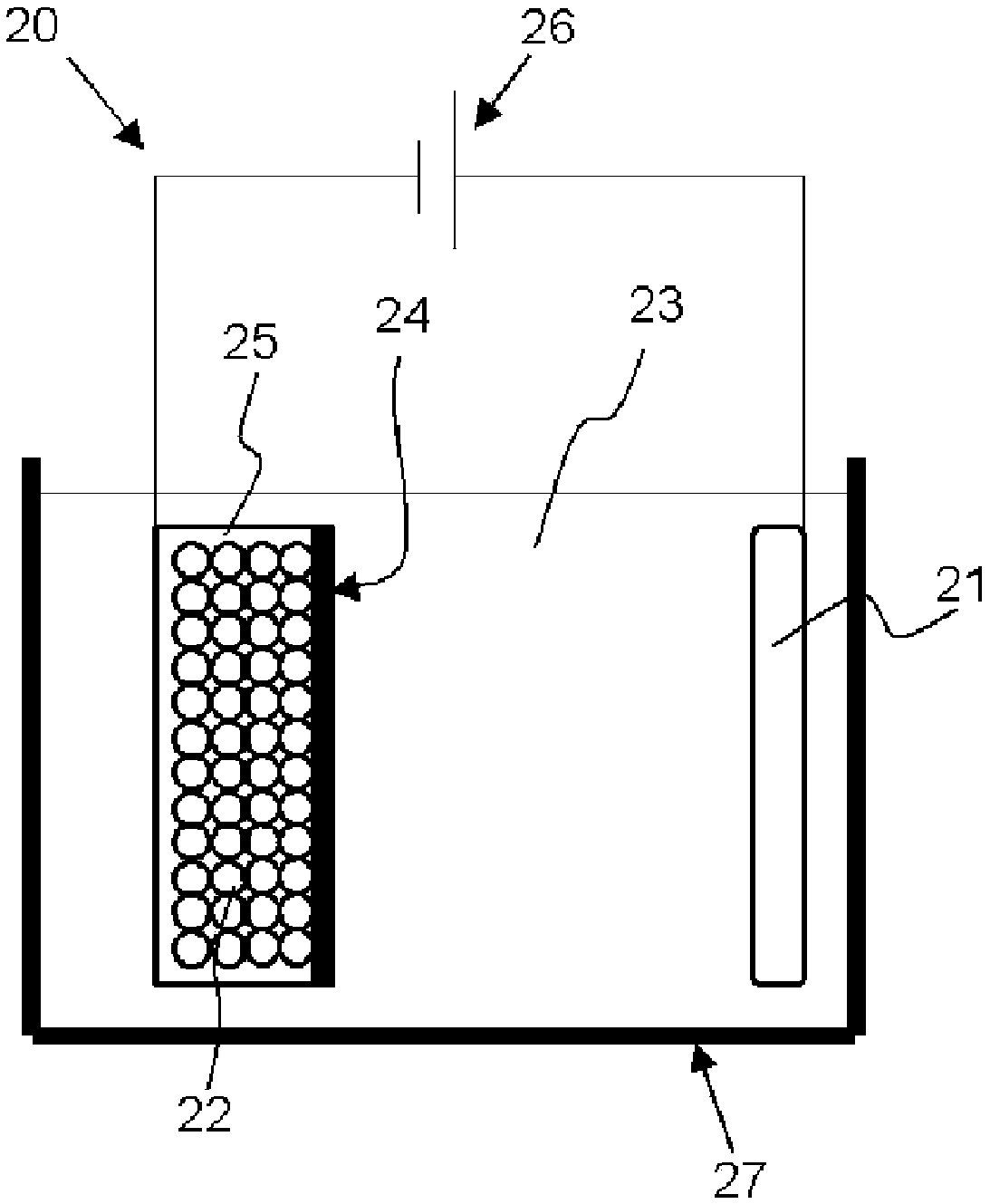

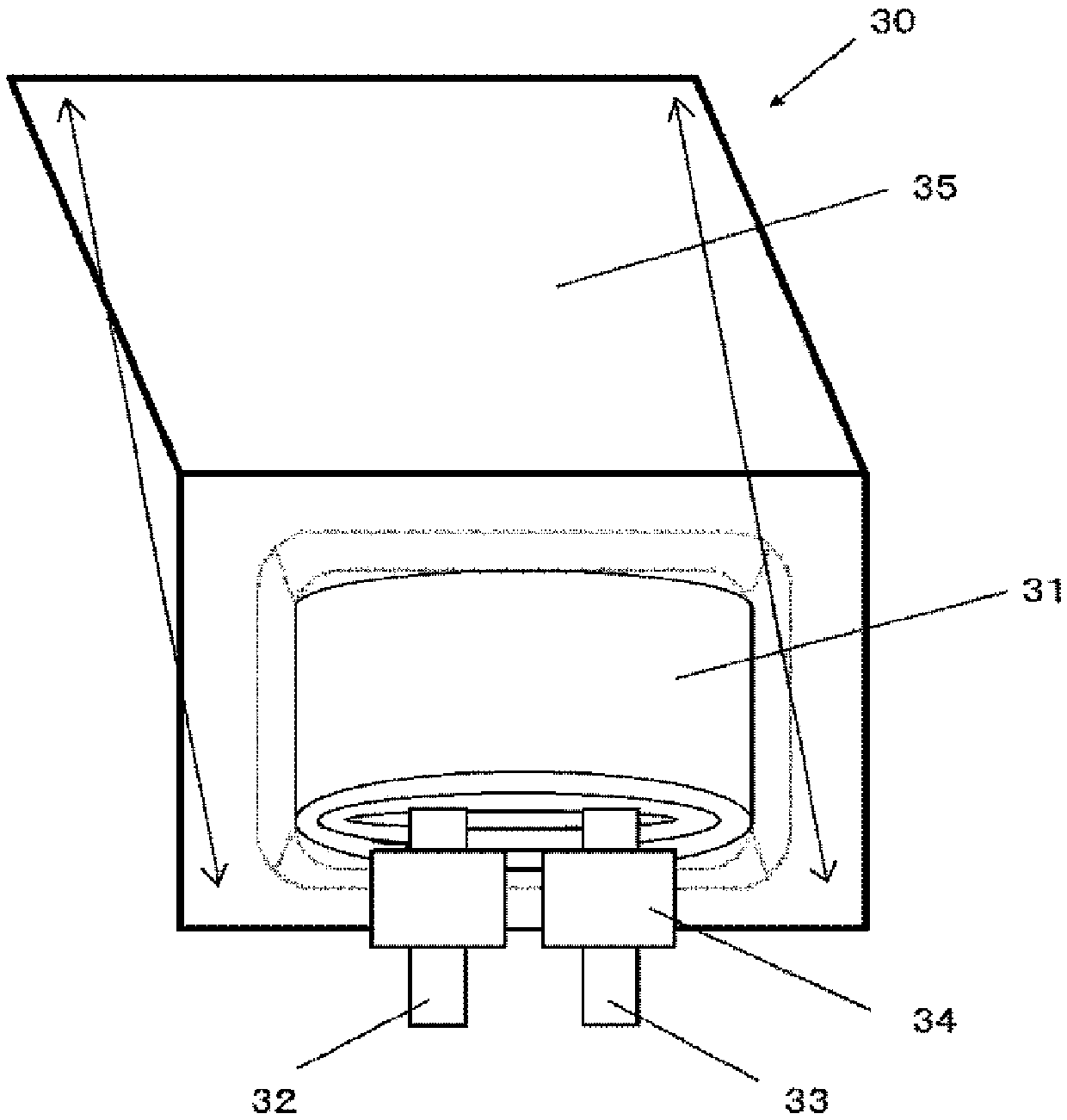

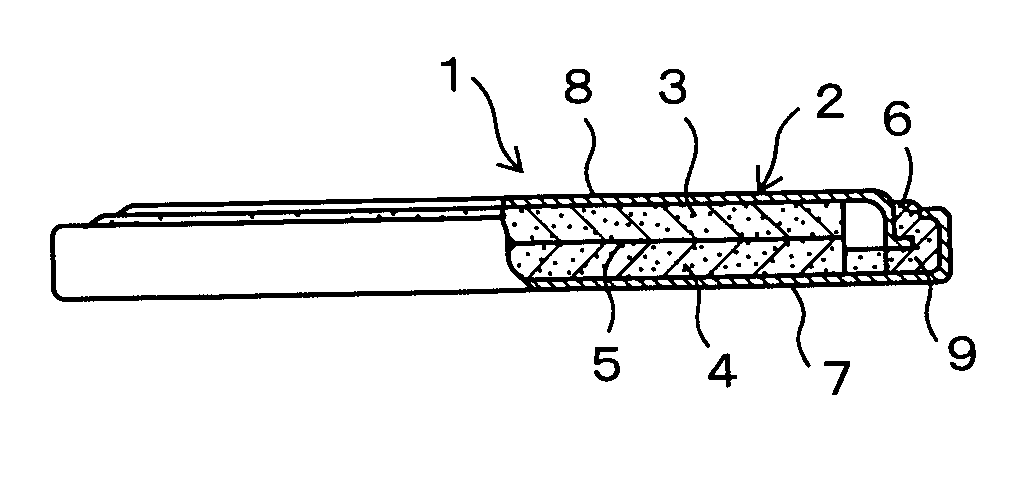

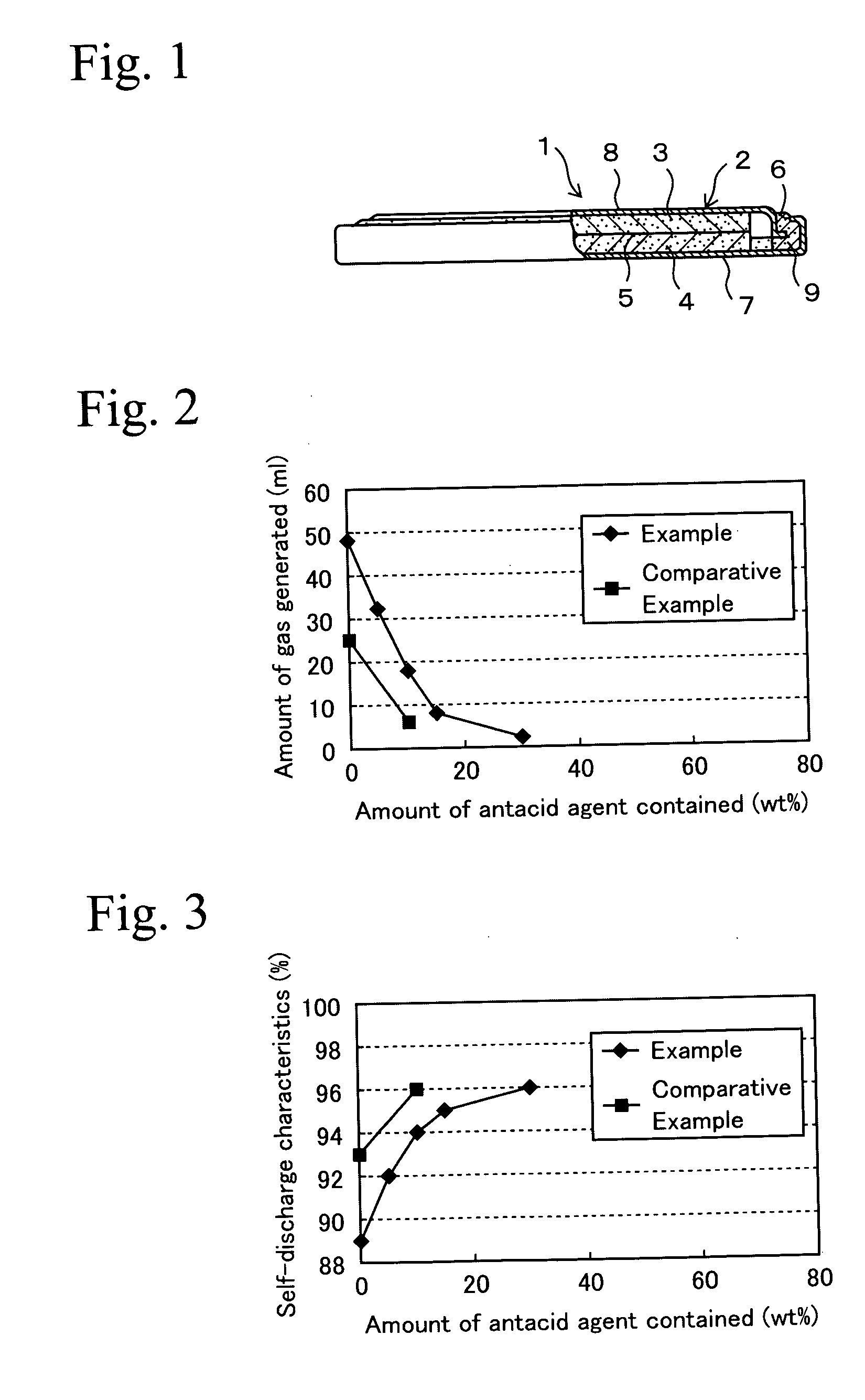

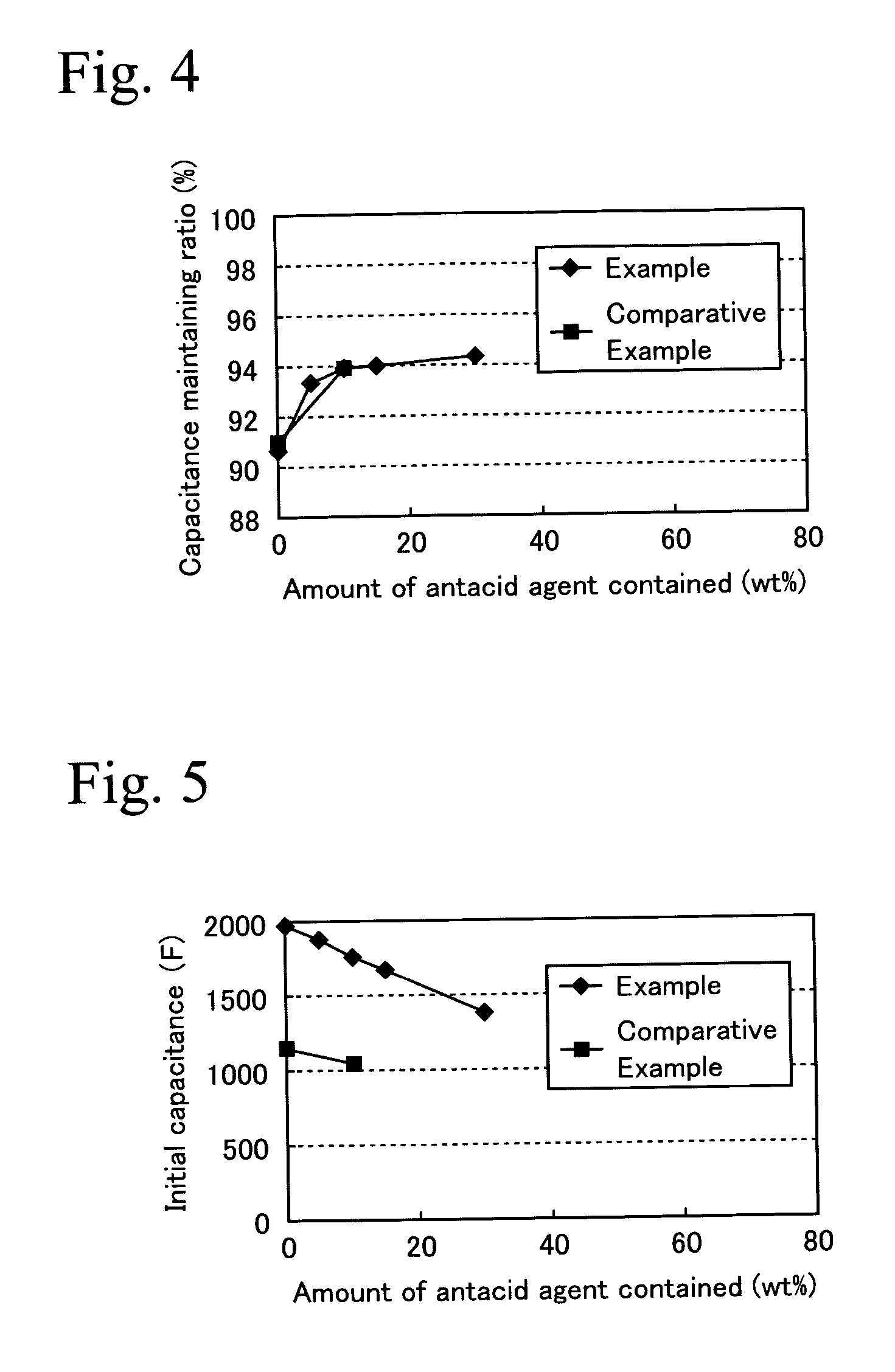

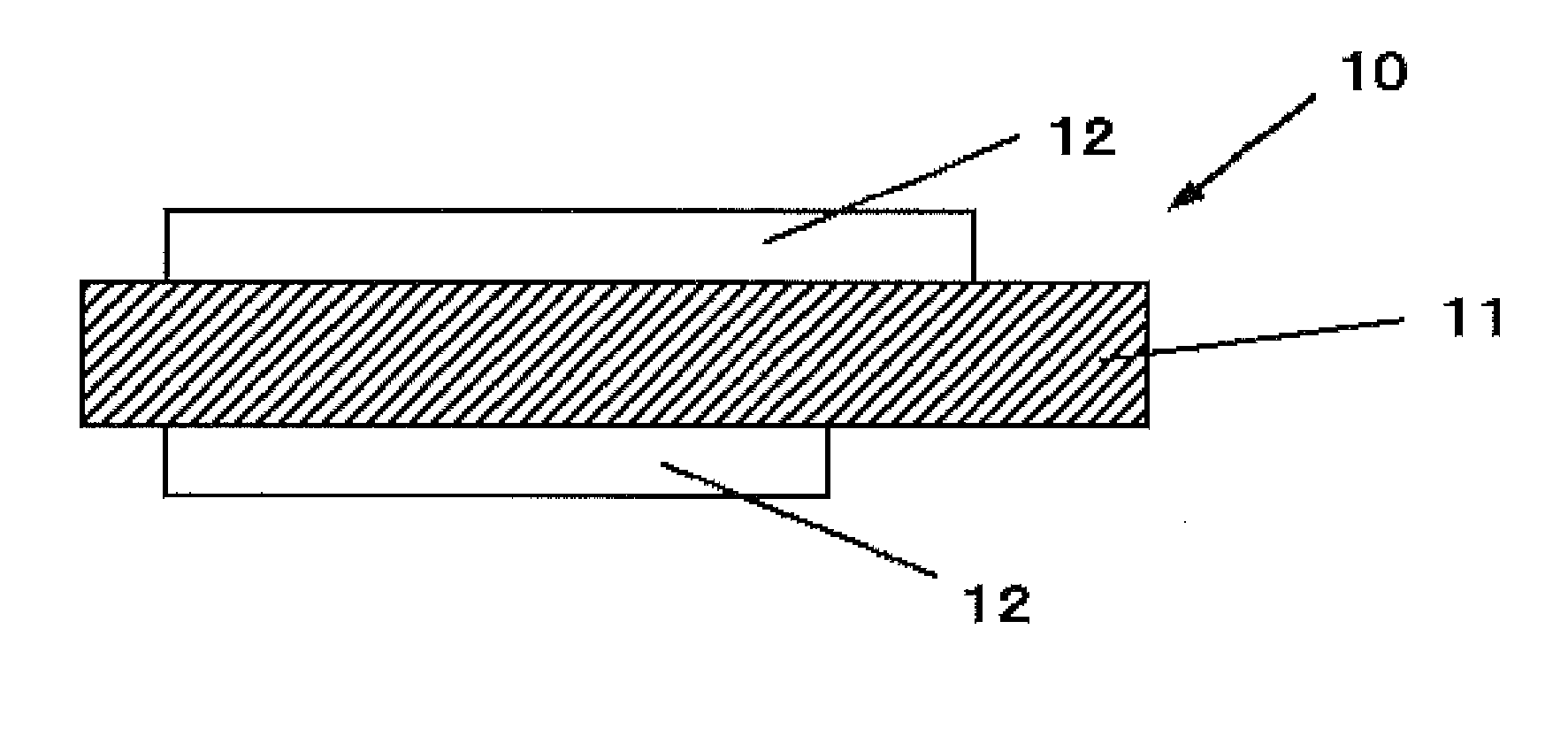

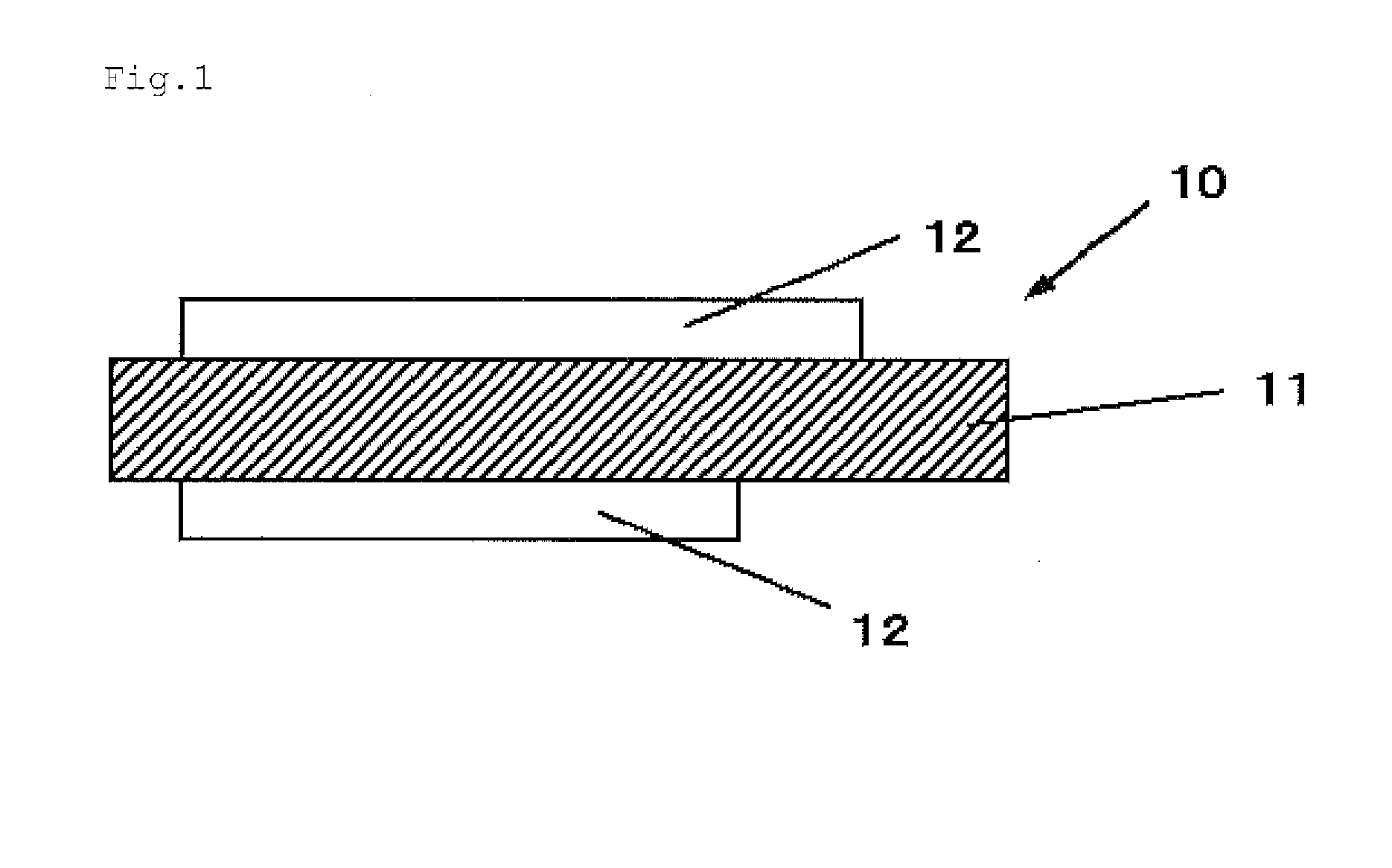

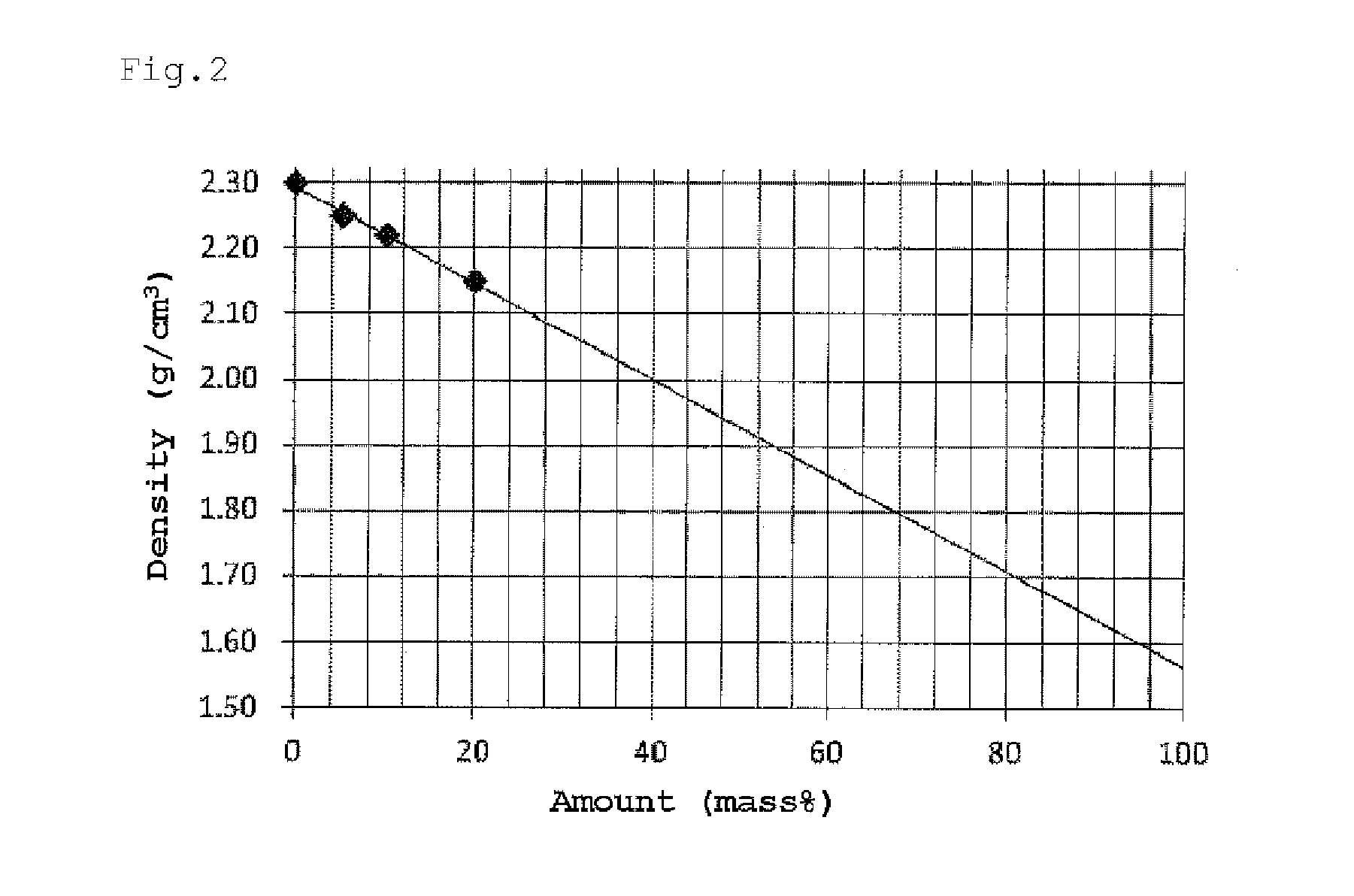

Electric double layer capacitor

InactiveUS20060209493A1Increase energy densityImprove initial efficiencyHybrid capacitor electrolytesLiquid electrolytic capacitorsWater basedActivated carbon

An electric double layer capacitor in which gas generation due to decomposition of a solvent of an electrolyte solution in the capacitor is reduced and performance maintaining ratio is superior, is provided by a method which is different from a method of adding additives to the electrolyte solution. The electric double layer capacitor has activated carbon polarizing electrodes and a non-water-based solvent, and a positive electrode of the activated carbon polarizing electrodes contains an antacid agent.

Owner:HONDA MOTOR CO LTD

Negative electrode active material for non-aqueous electrolyte secondary battery, negative electrode for non-aqueous electrolyte secondary battery, non-aqueous electrolyte secondary battery, and method of producing negative electrode material for a non-aqueous electrolyte secondary battery

ActiveUS20160254537A1Excellent capacity retention rateImprove initial efficiencyLi-accumulatorsNon-aqueous electrolyte accumulator electrodesCarbon coatedNon aqueous electrolytes

A negative electrode active material for a non-aqueous electrolyte secondary battery, including negative electrode active material particles containing a silicon compound expressed by SiOx where 0.5≦x≦1.6, the negative electrode active material particles at least partially coated with a carbon coating, the carbon coating exhibiting a specific surface area ranging from 5 m2 / g to 1000 m2 / g, the specific surface area being measured by a multipoint BET method after the carbon coating is separated from the negative electrode active material particles, the carbon coating exhibiting a compression resistivity ranging from 1.0×10−3 Ω·cm to 1.0 Ω·cm when the carbon coating is compressed so as to have a density of 1.0 g / cm3, the compression resistivity being measured after the carbon coating is separated from the negative electrode active material particles. This negative electrode active material can increase the battery capacity and improve the cycle performance and battery initial efficiency.

Owner:SHIN ETSU CHEM IND CO LTD

Negative active material for a rechargeable lithium battery, a method of preparing the same, and a rechargeable lithium battery comprising the same

InactiveUS20130189585A1Improve featuresImprove initial efficiencyElectrode manufacturing processesNegative electrodesMaterials scienceMetal

Negative active materials for rechargeable lithium batteries, methods of manufacturing the negative active materials, and rechargeable lithium batteries including the negative active materials are provided. One negative active material includes an active metal core and a crack inhibiting layer formed on the core. The crack inhibiting layer includes a carbon-based material.

Owner:SAMSUNG SDI CO LTD

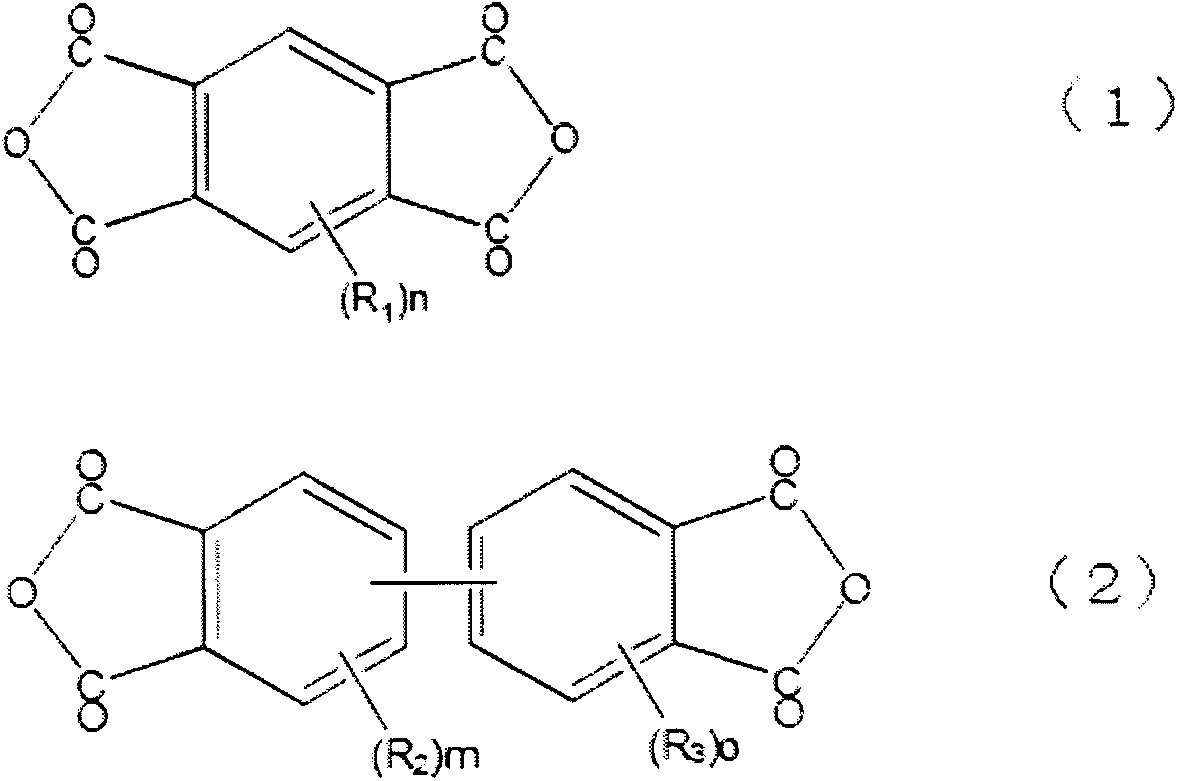

Binder for electrodes of lithium ion batteries, paste for negative electrodes of lithium ion batteries, and method for producing negative electrode of lithium ion battery

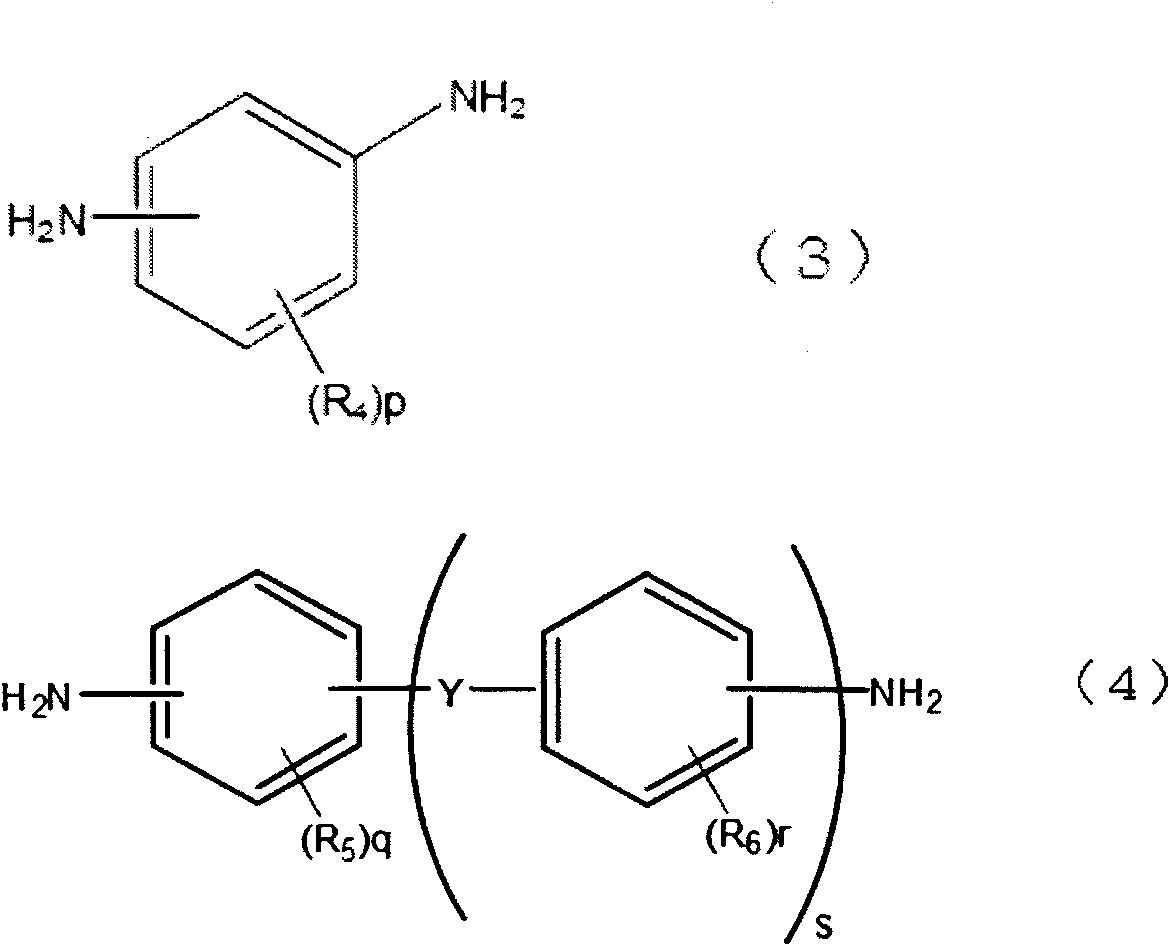

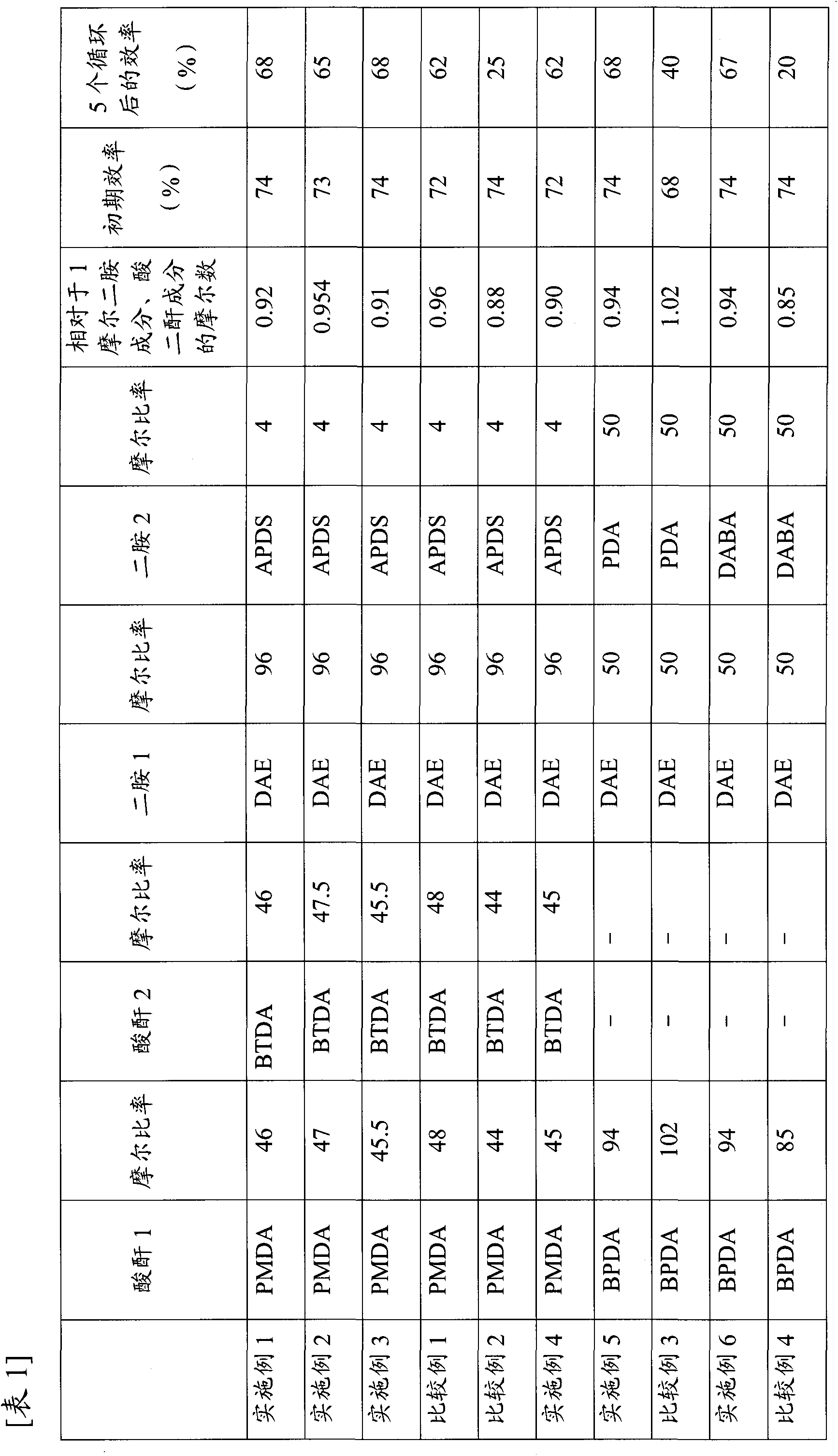

The present invention is directed to a binder for a lithium ion battery electrode, comprising a polyimide precursor having a tetracarboxylic acid residue and a diamine residue and / or a polyimide, the polyimide precursor having a residue of a tetracarboxylic dianhydride selected from those represented by the following general formulas (1) and (2) as the tetracarboxylic acid residue, and a residue of a diamine selected from those represented by the following general formulas (3) and (4) as the diamine residue, the content of the acid residue being from 0.90 to 0.95 moles based on 1 mole of the diamine residue.

Owner:TORAY IND INC

Method For Producing Negative Electrode For Lithium Secondary Battery

InactiveUS20080095930A1Large in theoretical capacityGood suppression characteristicsPrimary cellsElectrode carriers/collectorsLithiumSputtering

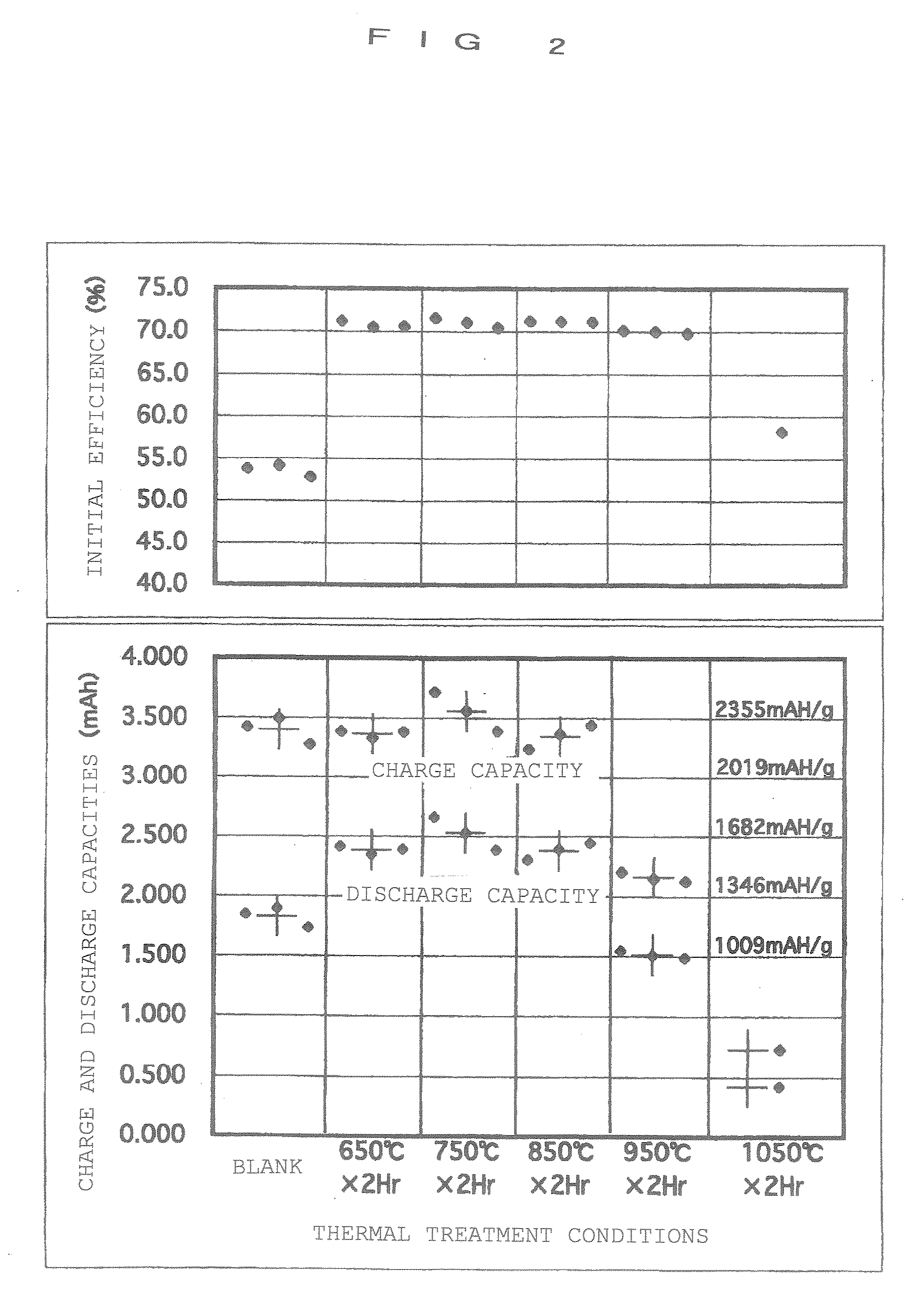

The lowness of the initial efficiency which is a drawback of lithium secondary batteries wherein a SiO negative electrode is used is largely made better without hindering a large initial charge capacity peculiar to the lithium secondary batteries. A fall in the cycle characteristic when the thickness of the SiO layer is made large is prevented. To realize these matters, a thin film of SiO is formed, as a negative electrode active material layer, on the surface of a current collector by vacuum evaporation or sputtering. The film is preferably formed by an ion plating process. The thickness of the SiO thin film is set to 5 μm or more. The surface roughness of the current collector is set to follows: the maximum height roughness Rz=5.0 or more. After the formation of the thin film, the film is thermally treated in a nonoxidative atmosphere.

Owner:OSAKA TITANIUM TECHNOLOGIES

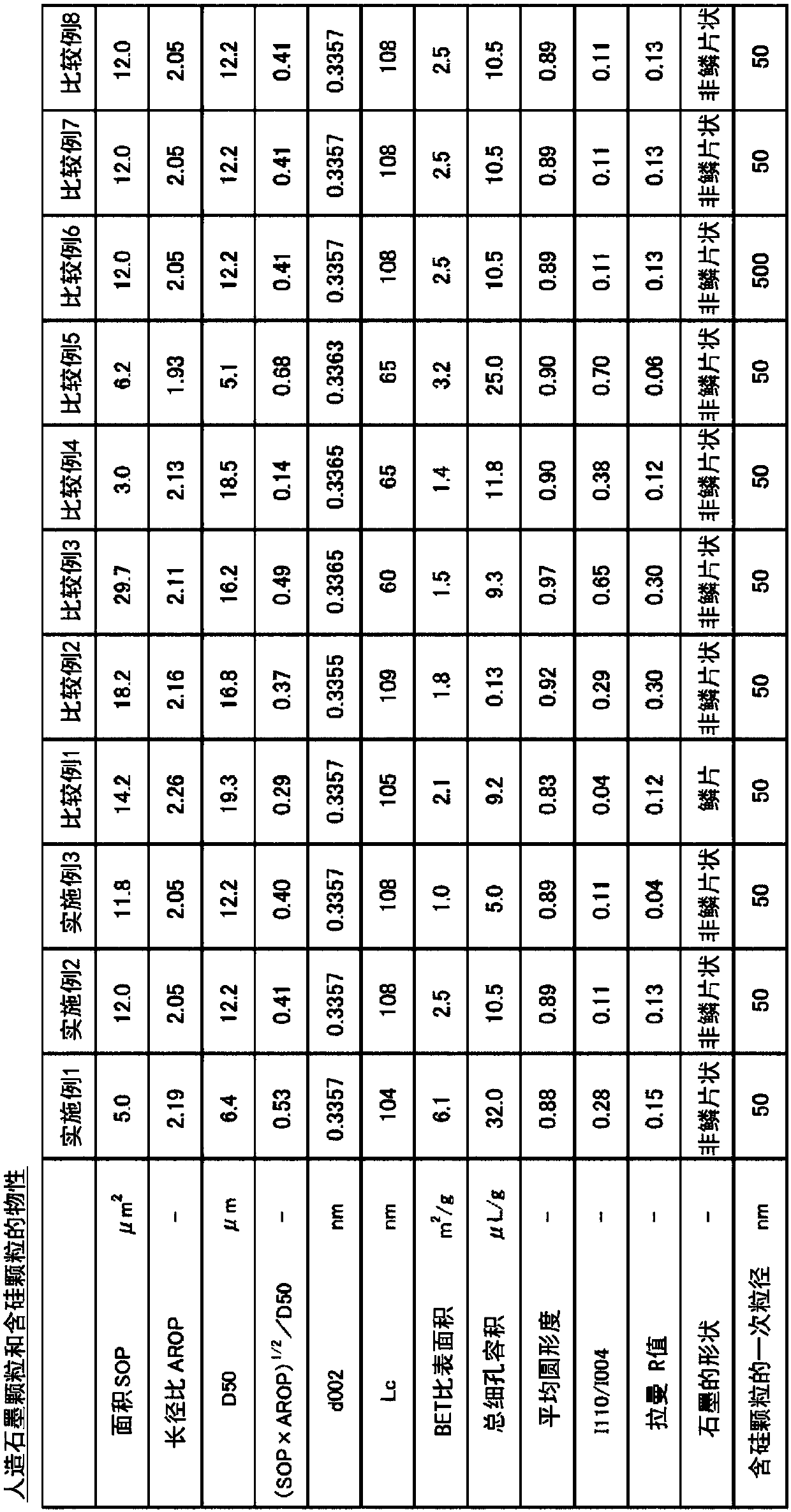

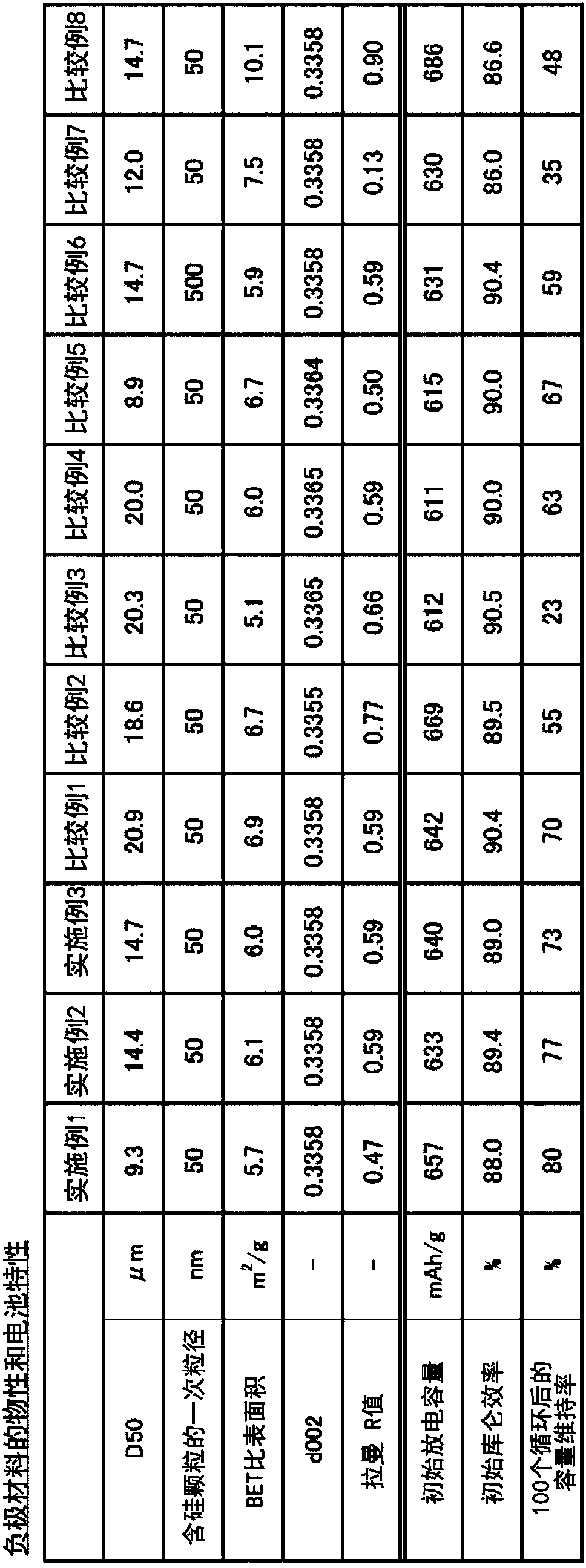

Negative electrode material for lithium-ion batteries and use therefor

ActiveCN107710467AImprove discharge capacityImprove initial efficiencySilicaSiliconUnit massCharge discharge

Owner:株式会社力森诺科 +1

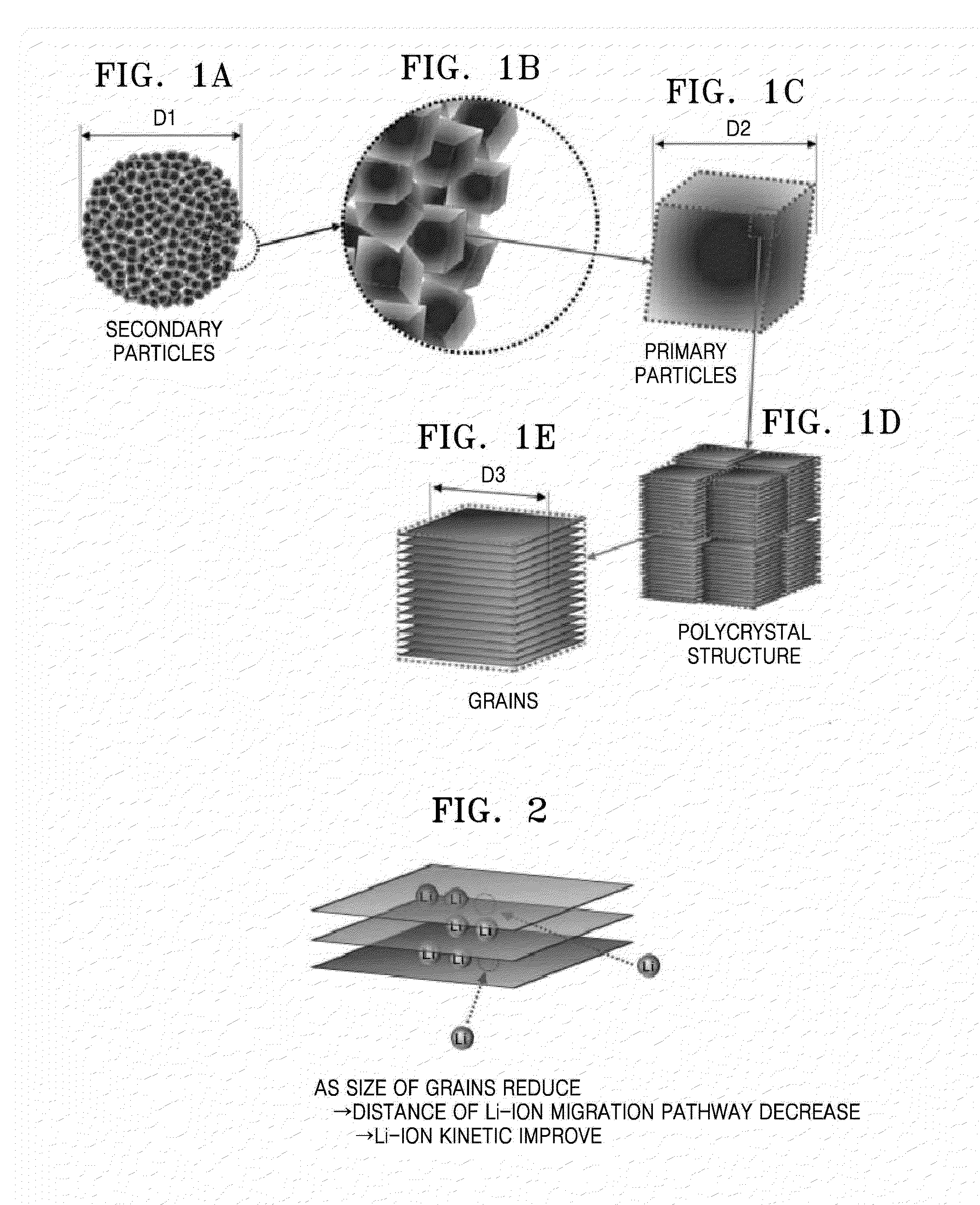

Positive electrode active material, lithium battery containing the same, and method of manufacturing the positive electrode active material

InactiveUS20150243978A1Improve discharge performanceImprove initial efficiencyAlkali metal oxidesPositive electrodesPhysical chemistryLithium battery

A positive electrode active material including a lithium transition metal oxide, wherein when a lithium battery including a positive electrode including the lithium transition metal oxide is analyzed by differential capacity analysis, an irreversible peak is present in a graph of differential capacity versus voltage in a range of about 4.5 volts versus lithium to about 4.8 volts versus lithium during a first charge / discharge cycle.

Owner:SAMSUNG ELECTRONICS CO LTD

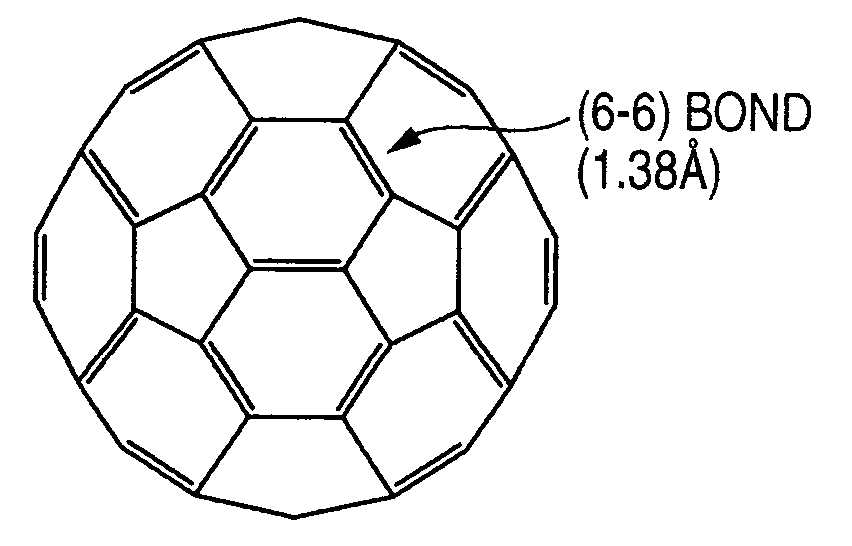

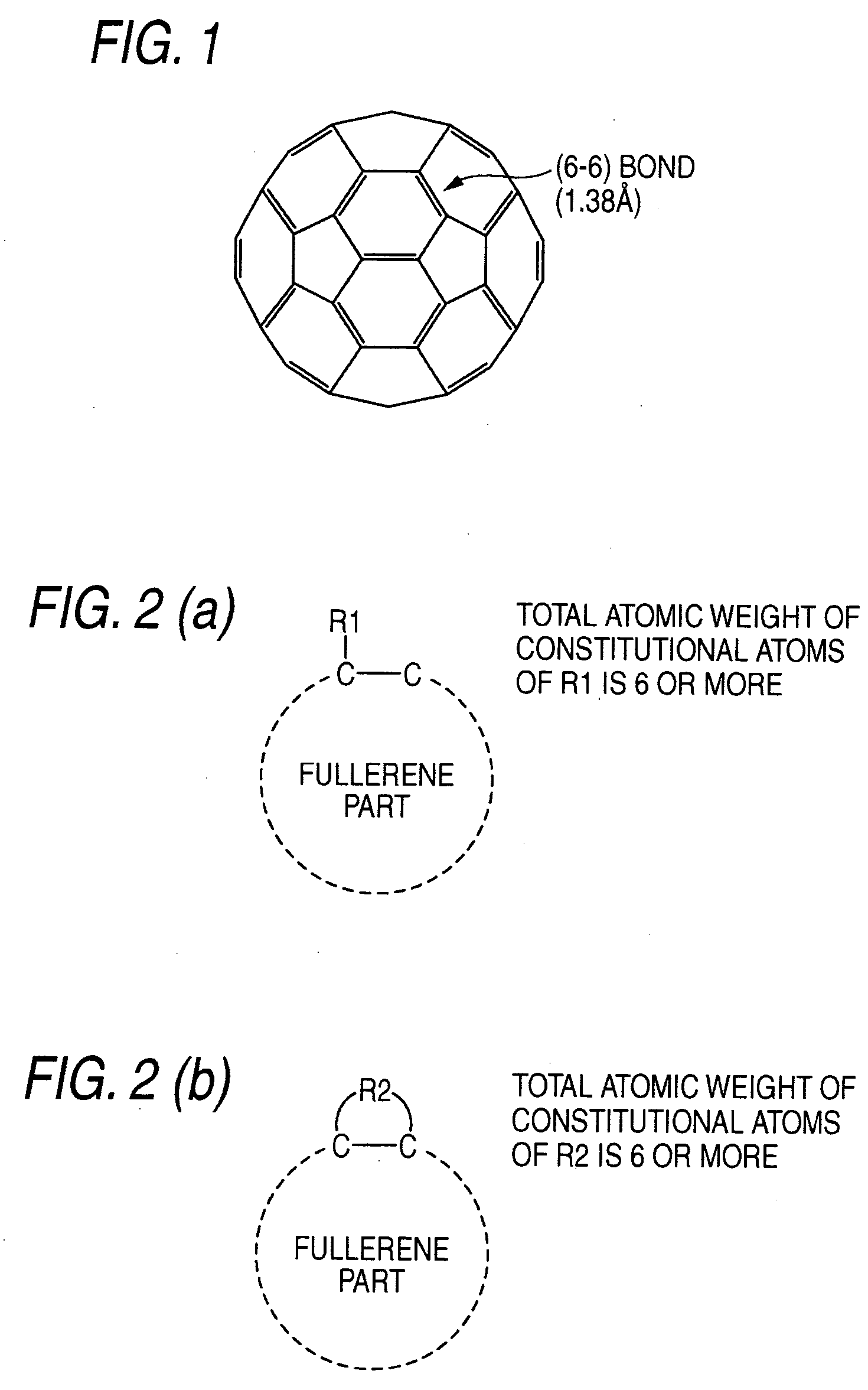

Additive for anode material for lithium secondary battery, anode material for lithium secondary battery, anode and lithium secondary battery using the anode material for lithium secondary battery

InactiveUS20050221184A1Efficient chargingImprove initial efficiencyConductive materialSecondary cellsHalogenSulfur

An object of the invention is to provide such an additive for a lithium secondary battery that improves the battery capacity and the initial efficiency of the lithium secondary battery. In the invention, a fullerene derivative having a group having a formula weight of 6 or more is used as an additive for a lithium secondary battery. A fullerene derivative having a group having a formula weight of 6 or more is contained in an anode material for a lithium secondary battery, an anode for a lithium secondary battery, and a lithium secondary battery using an anode containing the anode material. The group having a formula weight of 6 or more in the fullerene derivative is preferably one selected from the group consisting of an alkali metal atom, a chalcogen atom, a halogen atom, an aliphatic hydrocarbon group, an aromatic hydrocarbon group, a heterocyclic group, a characteristic group containing oxygen, a characteristic group containing sulfur and a characteristic group containing nitrogen.

Owner:MITSUBISHI CHEM CORP

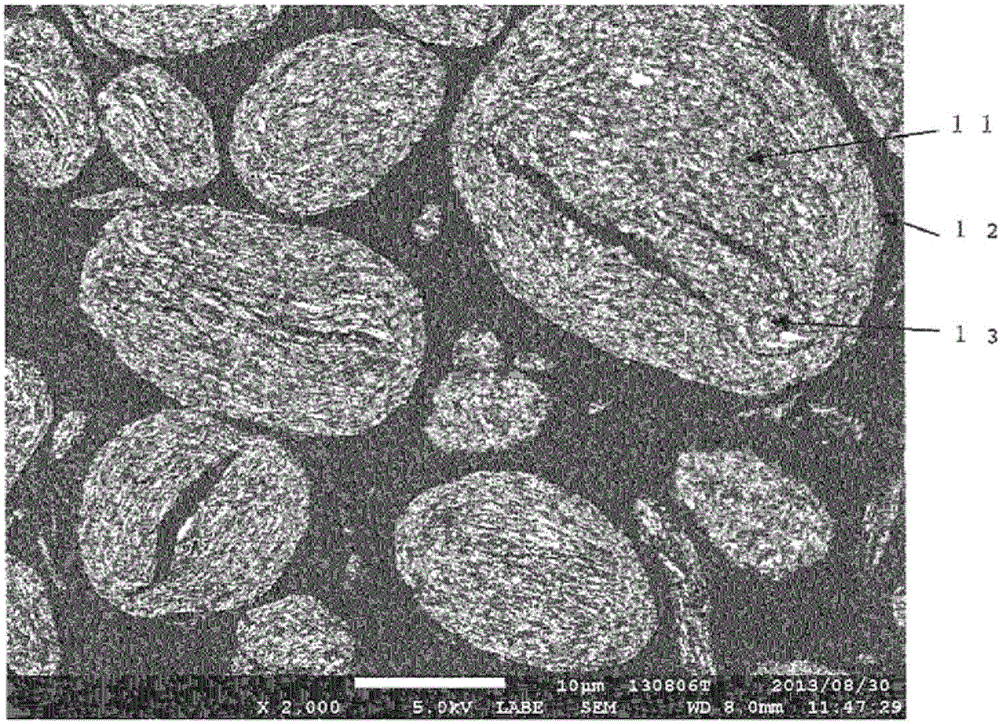

Composite active material for lithium ion secondary batteries and method for producing same

ActiveUS20170084913A1High bulk densityExcellent cycle characteristicsElectrode thermal treatmentFinal product manufactureLithiumGraphite

Provided are: an anode active material for a lithium ion secondary battery with which high initial efficiency and battery capacity can be maintained and excellent cycling characteristics are achieved; and a method for producing such an active material. The anode active material for a lithium ion secondary battery, the active material comprising a Si compound and a carbonaceous material or a carbonaceous material and graphite, is obtained by a method comprising the steps of:mixing a Si compound, a carbon precursor, and, as appropriate, graphite powder;performing granulation / compaction;pulverizing the mixture to form composite particles;firing the composite particles in an inert gas atmosphere; andsubjecting the pulverized and conglobated composite powder or the fired powder to air classification.

Owner:TOSOH CORP

Negative electrode active material for lithium ion secondary battery, and method for producing same

ActiveCN106133956AHigh bulk densityIncrease energy densityElectrode thermal treatmentFinal product manufactureElectrical batteryGraphite

Provided are: a negative electrode active material for a lithium ion secondary battery with which high initial efficiency and battery capacity can be maintained and excellent cycling characteristics achieved; and a method for producing said active material. This negative electrode active material for a lithium ion secondary battery, said active material comprising an Si compound, and a carbon substance or a carbon substance and graphite, is obtained by means of: a step of mixing an Si compound, a carbon precursor, and, in accordance with requirements, a graphite powder; a step of granulation / compaction; a step of pulverizing the mixture to form composite particles; a step of firing the composite particles in an inert gas atmosphere; and a step of subjecting the pulverized and spheroidized composite powder or the fired powder to air classification.

Owner:TOSOH CORP

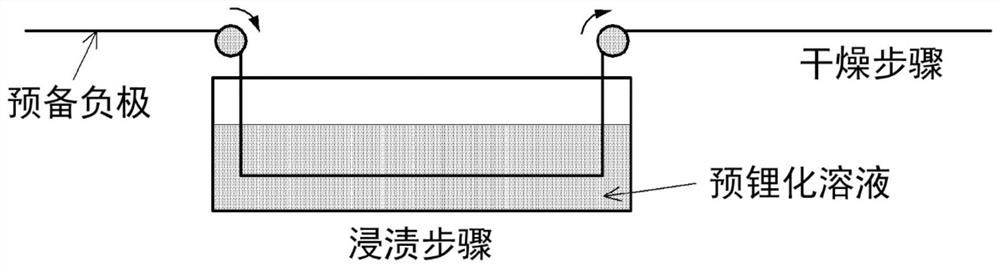

Method for manufacturing negative electrode

ActiveCN111615769AImprove initial efficiencyIncrease capacityElectrochemical processing of electrodesSecondary cellsPhysical chemistryLithium compound

The present invention relates to a method for manufacturing a negative electrode, the method comprising the steps of: immersing a preliminary negative electrode in a pre-lithiation solution containingan organic lithium compound and a pre-lithiation solvent; and taking the preliminary negative electrode out of the pre-lithiation solution, and then removing the pre-lithiation solvent present on thepreliminary negative electrode, wherein the preliminary negative electrode comprises a current collector and a preliminary negative electrode active material layer disposed on the current collector,the preliminary negative electrode active material layer containing a negative electrode active material, and the standard reduction potential of the organic lithium compound is lower than the standard reduction potential of the negative electrode active material.

Owner:LG ENERGY SOLUTION LTD

Carbon material, method for producing carbon material, and non-aqueous secondary battery using carbon material

ActiveCN107112536AIncrease capacityEasy to fillGraphiteElectrode carriers/collectorsLithiumElectrical resistance and conductance

Owner:MITSUBISHI CHEM CORP

Graphite material, method for producing same, carbon material for battery electrodes, and battery

InactiveCN103328378AImprove initial efficiencyIncrease capacityGraphiteCell electrodesCurrent loadHard X-rays

The present invention provides: a graphite material which is suitable as an electrode material for nonaqueous electrolyte secondary batteries; a method for producing the graphite material; a carbon material for battery electrodes; and an excellent secondary battery which has an extremely small irreversible capacity,while maintaining charge / discharge cycle characteristics, large-current load characteristics and discharge capacity at high levels. A graphite material, wherein the oxygen amount (a) (mass%) in the region from the particle surface to 40 nm in the depth direction is within the range of 0.010<= a <= 0.04 as determined by the peak intensity of O1s obtained by HAX-PES measurement using a hard X-ray of 7,940 eV, can be used as a carbon material for battery electrodes that have excellent initial efficiency and small irreversible capacity, while maintaining large-current load characteristics, cycle characteristics and discharge capacity at high levels.

Owner:RESONAC HOLDINGS CORPORATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com