Negative electrode material for lithium-ion batteries and use therefor

A technology for lithium-ion batteries and negative electrode materials, applied in battery electrodes, positive electrodes, secondary batteries, etc., can solve the problems of inability to obtain capacity, increase in internal resistance, large expansion rate and shrinkage rate, etc., and achieve excellent charge-discharge cycle characteristics , Excellent initial efficiency and large discharge capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

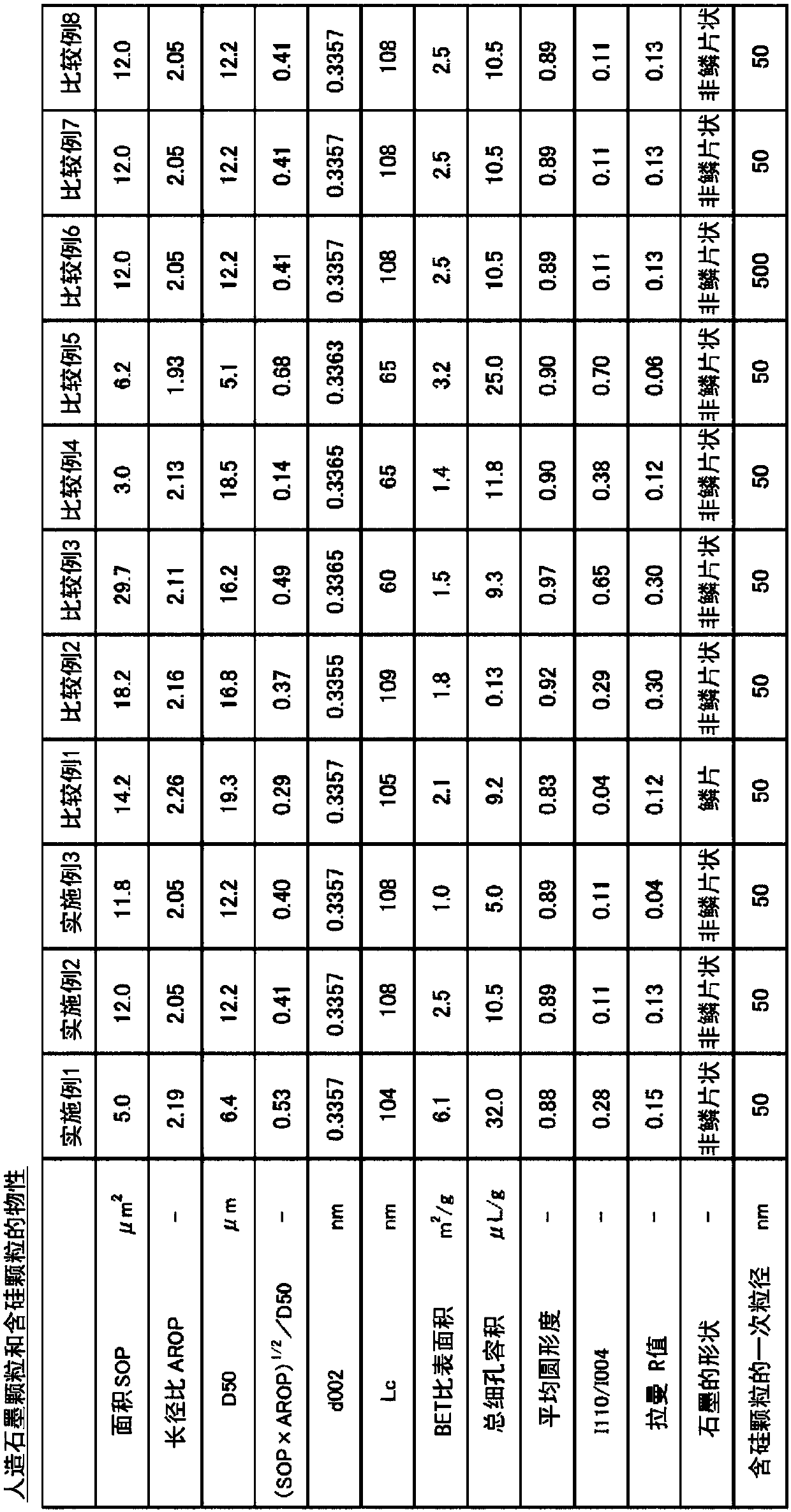

Embodiment 1

[0209] Crude oil produced in Liaoning Province, China (API28, wax content 17% by mass, sulfur content 0.66% by mass) was distilled at atmospheric pressure, and the heavy fraction was distilled at 510°C under normal pressure using a sufficient amount of Y-type zeolite catalyst. Bed catalytic cracking. The solid components such as the catalyst are centrifuged until the obtained oil becomes clear to obtain a clarified oil. The oil is fed to a small delayed coking process. The drum inlet temperature is 505°C, and the internal pressure of the drum is maintained at 600kPa (6kgf / cm 2 ) After 10 hours, carry out water cooling to obtain black block. The obtained black mass was pulverized with a hammer so that the maximum size was about 5 cm, and then dried in a kiln at 200°C. Let this be coke 1.

[0210] This coke 1 was pulverized with a Bantam mill manufactured by Hosokawa Micron Corporation, and thereafter, the coarse powder was cut using a sieve having a hole diameter of 45 μm. ...

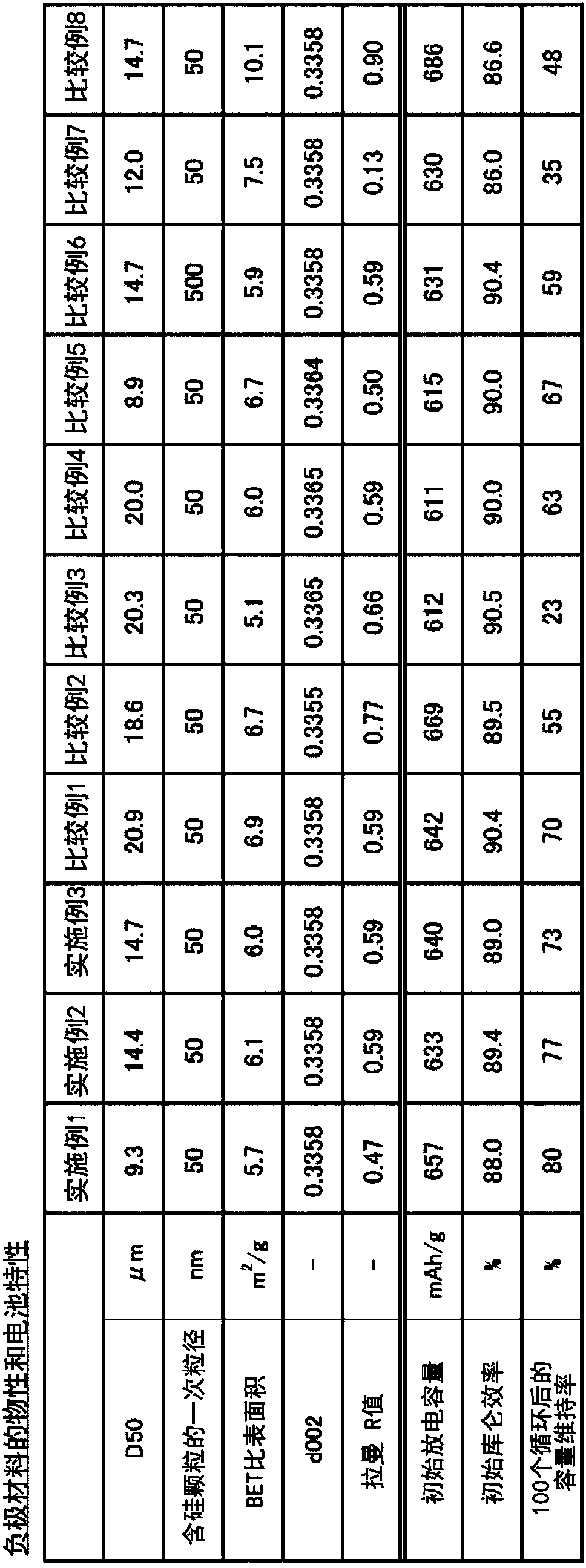

Embodiment 2

[0217] The coke 1 described in Example 1 was pulverized with a Bantam mill manufactured by Hosokawa Micron Corporation, and then the coarse powder was cut using a sieve with a hole diameter of 45 μm. The pulverized coke 1 was further pulverized with a jet mill manufactured by SEISHIN ENTERPRISEC Co., Ltd. Next, airflow classification was performed with a turbo classifier TC-15N manufactured by Nisshin Engineering, to obtain powdered coke 2 (D50=12.0 μm) substantially free of particles with a particle diameter of 1.0 μm or less.

[0218] The powdered coke 2 was filled in a graphite crucible, and heat-treated in an Acheson furnace for one week so that the highest temperature reached about 3300° C., to obtain non-flaky artificial graphite particles (B2). At this time, the graphite crucible is provided with a plurality of ventilation holes. Table 1 shows various physical properties of the obtained non-flaky artificial graphite particles (B2). D50 is 12.2μm, BET specific surface ...

Embodiment 3

[0222] The powdered coke 2 described in Example 2 was filled into a graphite crucible, and heat-treated for one week so that the maximum temperature in the Acheson furnace became about 3300° C., to obtain non-flaky artificial graphite particles (B3) . Table 1 shows various physical properties of the obtained non-flaky artificial graphite particles (B3). D50 is 12.2μm, BET specific surface area is 1.0m 2 / g, d002 is 0.3357nm, Lc is 108nm, total pore volume is 5.0μL / g, average circularity is 0.89, orientation I 110 / I 004 is 0.11.

[0223] Thereafter, a composite material (3) was obtained in the same manner as in Example 1, except that the artificial graphite particles (B3) were used instead of the artificial graphite particles (B1) in Example 1.

[0224] Table 2 shows the results of evaluating the powder physical properties and battery characteristics of this composite material (3).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com