Negative electrode active material for lithium ion secondary battery, and method for producing same

一种负极活性物质、二次电池的技术,应用在电极制造、二次电池、活性物质电极等方向,能够解决没有达到、难以破裂等问题,达到高初期效率、优异循环特性、抑制电解液与硅的反应的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

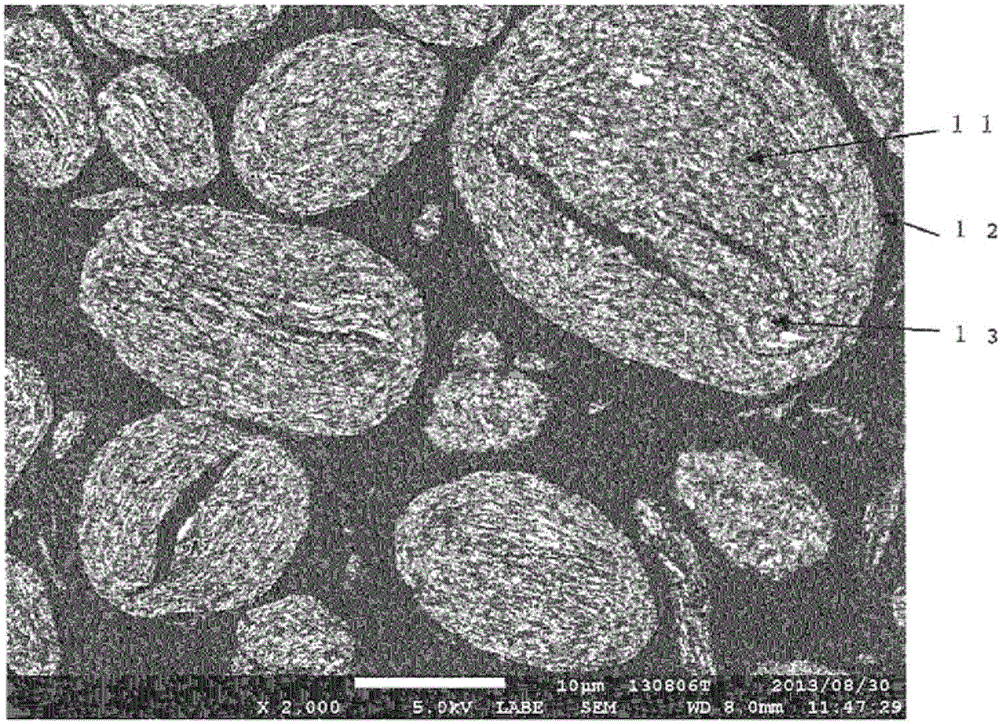

[0163] Chemical grade metal Si (purity 3N) with an average particle diameter (D50) of 7 μm was mixed with 25% by weight of ethanol, and pulverized for 6 hours in a finely pulverized wet bead mill using zirconia beads with a diameter of 0.3 mm to obtain The average particle size (D50) is 0.3μm, and the BET specific surface area when dry is 60m 2 / g of ultrafine Si slurry.

[0164] Natural graphite with a particle size of 0.5 mm (width in the (200) plane direction) and a thickness of 0.02 mm was immersed in a liquid containing 1% by weight of sodium nitrate and 7% by weight of potassium permanganate in concentrated sulfuric acid for 24 hours, Thereafter, it was washed with water and dried to obtain acid-treated graphite. Put the acid-treated graphite into a vibrating powder feeder, and pass through a mullite tube with a length of 1 m and an inner diameter of 11 mm heated to 850 ° C by an electric heater with nitrogen gas at a flow rate of 10 L / min, and release it into the atmos...

Embodiment 2

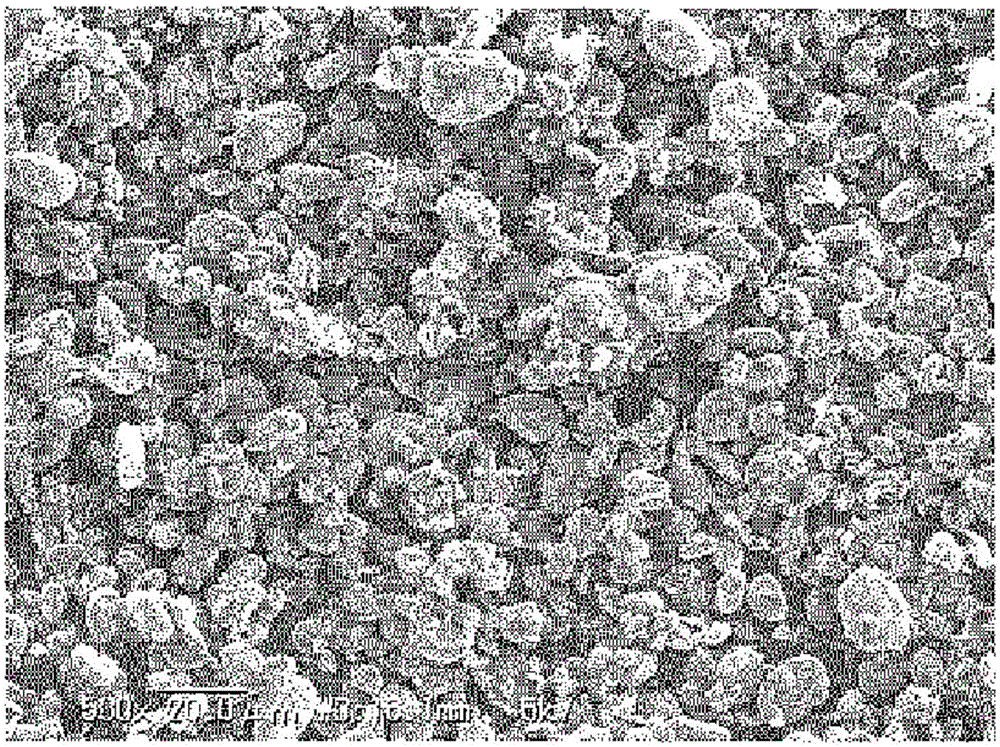

[0180] 36g of ultrafine particle Si slurry, 18g of expanded graphite, 7.5g of cresol-type phenolic resin (weight-average molecular weight (Mw)=490) and 2.4L of ethanol were put into a stirring container, and were carried out for 15 minutes of sonication. Thereafter, the mixed solution was transferred to a rotary evaporator, heated to 50° C. in a warm bath while rotating, and evacuated with an aspirator to remove the solvent. Thereafter, it was expanded into a rod shape in the ventilation pipe, and was dried for 2 hours while exhausting, passed through a sieve with a mesh size of 2 mm, and was further dried for 2 days to obtain 32 g of mixed dried product (untamped density 66 g / L).

[0181] The dried mixture was passed through a 3-roll mill twice, and granulated and compacted with a particle size of 2 mm and an untamped density of 340 g / L.

[0182] Next, the granulated / compacted product was put into a new pulverizer, and pulverized at 21,000 rpm for 900 seconds while water-coo...

Embodiment 3

[0196] Chemical grade metal Si (purity 3N) with an average particle diameter (D50) of 7 μm was mixed with ethanol at 21% by weight, and pulverized for 6 hours in a finely pulverized wet bead mill using zirconia beads with a diameter of 0.3 mm. Obtain an average particle size (D50) of 0.3 μm and a BET specific surface area of 100 m when dry 2 / g of ultrafine Si slurry.

[0197] Put the acid-treated natural graphite with a particle size of 0.3 mm (the width of the (200) plane direction) and a thickness of 10 μm into a vibrating powder feeder, and heat it to 850 ° C with an electric heater as nitrogen gas flows at a flow rate of 12 L / min. A mullite tube with a length of 1m and an inner diameter of 11mm is released into the atmosphere from the end surface, sulfurous acid and other gases are discharged from the upper part, and expanded graphite is collected in a stainless steel container at the lower part. The width of the expanded graphite in the (200) plane direction is 0.3mm,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com