Dispensing of gloves

a technology for dispensers and gloves, applied in the field of dispensers, can solve the problems of increasing the cost of mechanical complexity and the need, and reducing the number of gloves which can be packed in a given volume. , to achieve the effect of maximising the accessibility of the next glove and simplifying the manufacture and operation of the dispenser

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

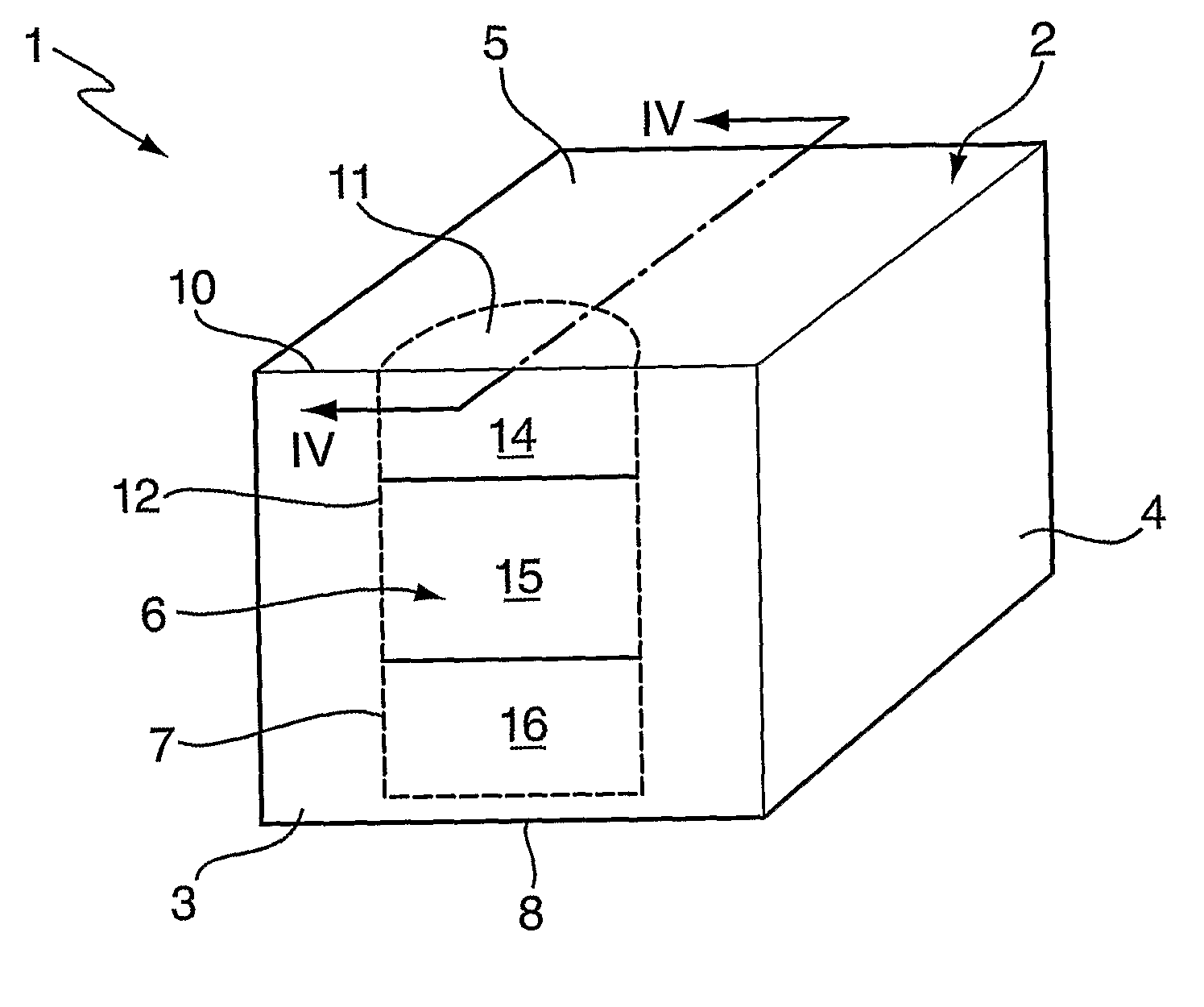

[0048]FIG. 1 shows a dispenser 1 for disposable gloves. The dispenser includes a nearly cubic container 2 which has six faces, three of which are visible in the drawing, including a front face 3, a right side face 4 and a top face 5. The container has a removable portion 6 which extends as a vertical strip 7 across the front face from near a bottom edge 8, to a top edge 10 and on to a semicircular area 11 of the top face 5. The removable portion 6 is temporarily held to adjacent portions of the container at a perforated line 12 in the container material that extends fully around the removable portion. The container is preferably formed of an inexpensive card-like material, for example cardboard.

[0049]The removable portion is subdivided horizontally into three sections 14, 15, 16 by means of a pair of parallel cuts 18, 19 that extend horizontally between opposite vertical sections of the perforated line 12 in the container front face 3. The cuts need not be full cuts through the cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com