Manufacturing method of high-moisture-proof and high-density fiber board

A technology of high-density fiberboard and manufacturing method, which is applied in the direction of manufacturing tools, flat products, and pretreatment of molding materials, etc., can solve the problems of intense polycondensation reaction, difficult to control the reaction, and reduced bonding strength, so as to achieve a reasonable degree of polymerization. Ease of operation and improved waterproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

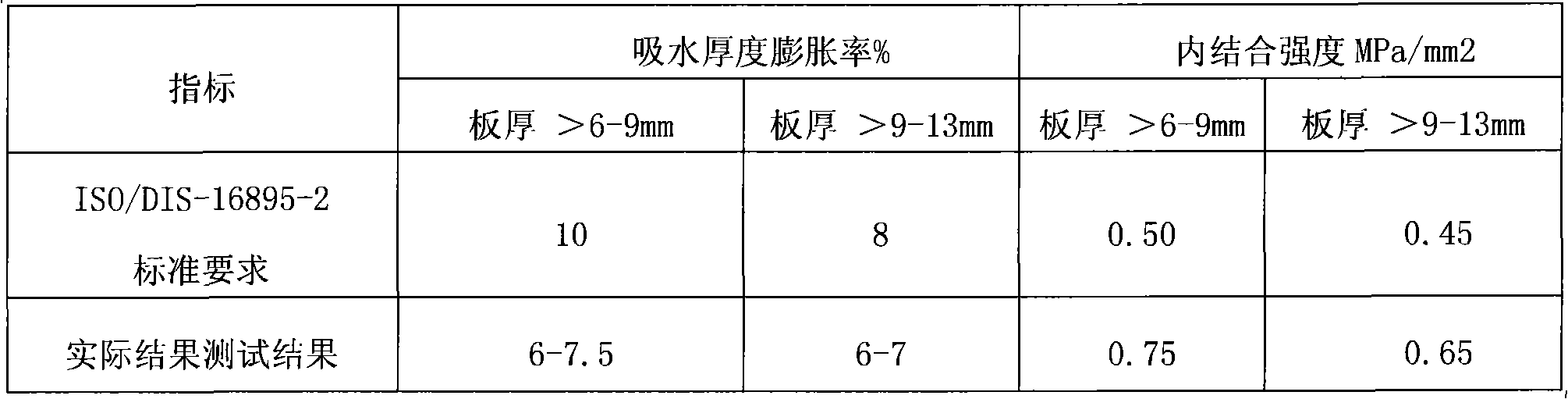

Embodiment 1

[0017] The production method of the high moisture-proof high-density fiberboard firstly produces melamine-formaldehyde resin and urea-formaldehyde resin respectively:

[0018] (1) Manufacturing method of moisture-proof melamine formaldehyde resin

[0019] Use 30% sodium hydroxide in the reaction kettle to adjust the formaldehyde solution to PH = 8.5, add melamine to the formaldehyde solution according to the molar ratio of formaldehyde and melamine as 2:1, and carry out polycondensation reaction at 80-90°C, polymerization reaction The time is about 1.5 hours, until the reaction viscosity is 40-55 centipoise (25°C), the temperature is lowered to 35°C, and stored under the condition of PH=8.5.

[0020] (2) Urea-formaldehyde resin production method:

[0021] Use 30% sodium hydroxide in the reaction kettle to adjust the formaldehyde solution to PH = 7.5, according to the above-mentioned total molar ratio of formaldehyde / urea = 1:1, add urea in stages, first carry out the addition...

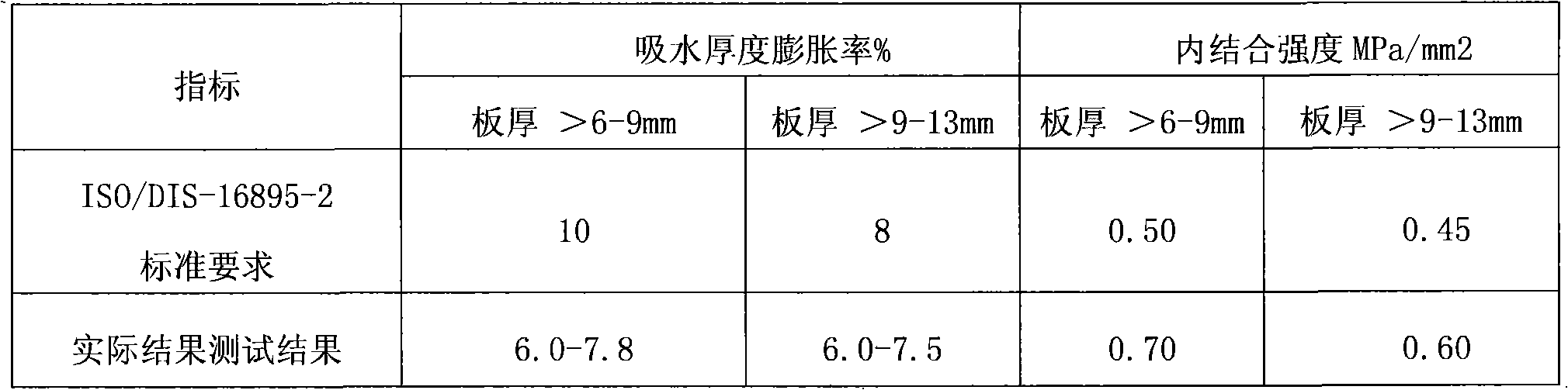

Embodiment 2

[0030] The production method of the high moisture-proof high-density fiberboard firstly produces melamine-formaldehyde resin and urea-formaldehyde resin respectively:

[0031] (1) Manufacturing method of moisture-proof melamine formaldehyde resin

[0032] Use 30% sodium hydroxide in the reaction kettle to adjust the formaldehyde solution to PH=9.0, add melamine to the formaldehyde solution according to the molar ratio of formaldehyde and melamine as 1.8:1, and carry out polycondensation reaction at 80-90°C, polymerization reaction The time is about 2.0 hours, until the reaction viscosity is 40-55 centipoise (25°C), the temperature is lowered to 35°C, and stored under the condition of PH=9.0.

[0033] (2) Urea-formaldehyde resin production method:

[0034] Use 30% sodium hydroxide in the reaction kettle to adjust the formaldehyde solution to PH = 7.5, according to the above-mentioned total molar ratio of formaldehyde / urea = 1:1, add urea in stages, first carry out the addition...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Plate thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com