Straw raw material clean co-production technology and efficient hot-pressing device

A raw material and high-efficiency technology, applied in fiber raw materials, fiber raw material processing, organic chemistry, etc., can solve the problems of increasing energy consumption and heat loss of straw cooking, reducing production efficiency of hydrolyzates, and polluting the environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] specific implementation

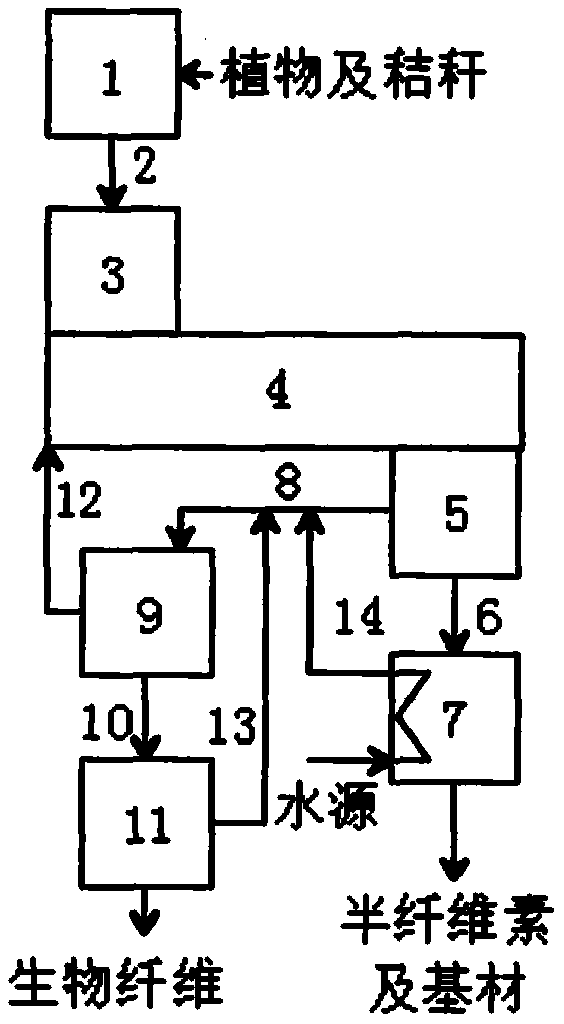

[0022] Attached below figure 1 A further analysis is made on the clean co-production technology of straw materialization and the high-efficiency hot-pressing device of the present invention.

[0023] Such as figure 1 As shown, the clean combined production technology of straw raw materials and the high-efficiency hot-pressing device of the present invention mainly prepare raw materials 1 from straws, raw material conveyors 2, raw material compression input machines 3, raw material cooking and hydrolysis containers 4, heat preservation and pressure unloading High temperature and high pressure solid-liquid separator 5, liquid phase conveyor 6, liquid phase waste heat and pressure utilization and production device 7, solid phase stirring and conveyor 8, high temperature and high pressure heat mill 9, heat mill steam purification heat supply device 10, Consists of a heat preservation and pressure-holding conveyor 11 for hot grinding materials, a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com