Papermaking defibrator

A thermal mill and grinding head technology, used in mechanical equipment, engine components, engine sealing, etc., can solve problems such as easy damage and poor sealing effect of grinding shafts, and achieve the effects of simple installation, improved efficiency, and reduced steam leakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

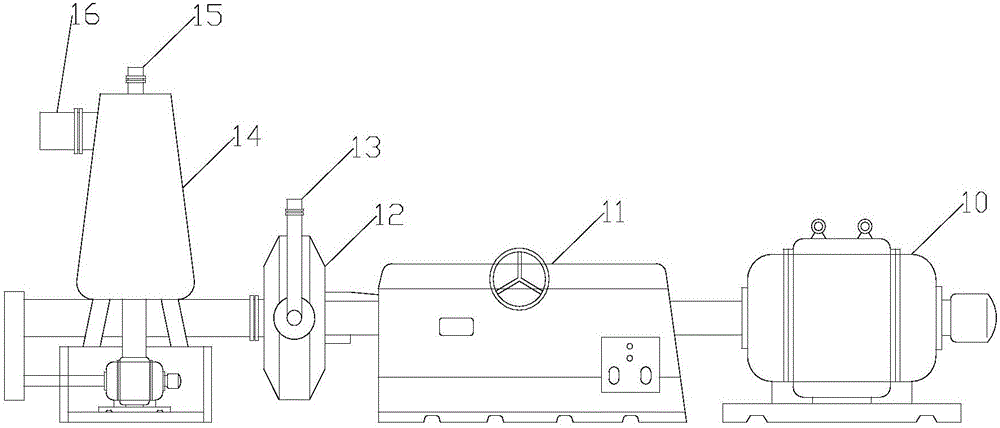

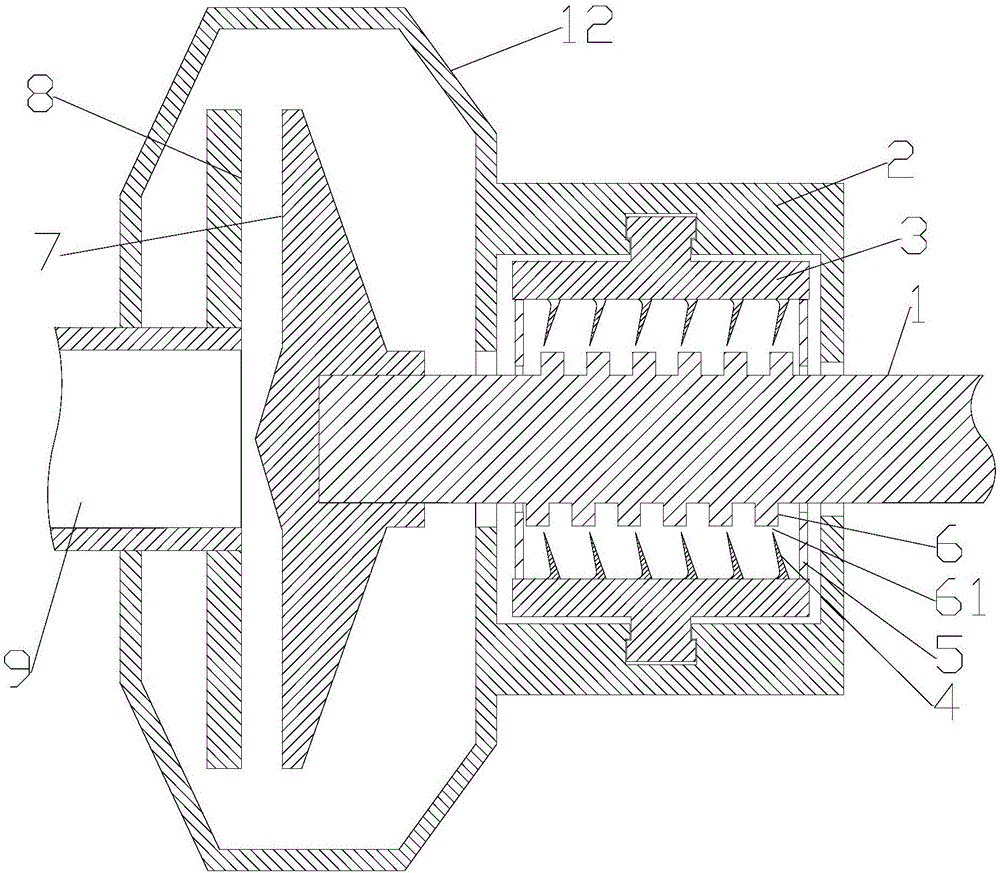

[0026] see figure 1 , figure 2 , a kind of papermaking heat mill, comprises motor 10, control part 11, grinding device 12, discharging device 13, preheating cooking device 14, steam pipe 15, feeder 16; The cooking device, the feeder is a screw feeder, and the preheating cooking device uses high-temperature and high-pressure steam to cook the material, and the cooked material enters the grinding device through the feeding pipe 9, and the motor supplies the grinding device with The power and control part detects the operation status of the paper-making heat refiner, and adjusts and controls it. The material is crushed, torn and cut off by the grinding device, and the ground wood pulp is discharged from the discharge device; if the seal is not ideal, it will affect the preheating and cooking equipment. The internal steam pressure and high temperature and high pressure steam leakage will affect the working state of the grinding shaft bearing and cause the vibration of the grindi...

Embodiment 2

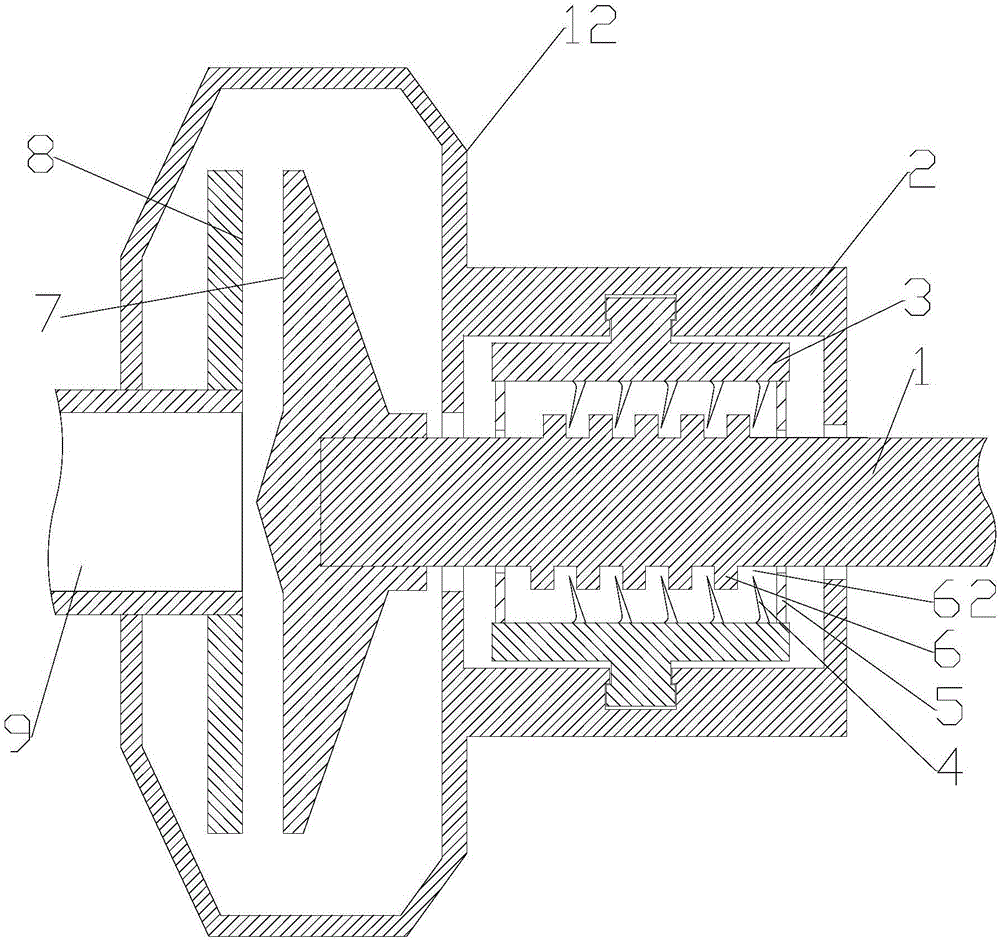

[0034] see figure 1 , image 3, The sealing mechanism in this embodiment is an improvement on the basis of Embodiment 1. The technical content disclosed in Embodiment 1 will not be described repeatedly, and the content disclosed in Embodiment 1 also belongs to the content disclosed in this embodiment.

[0035] see image 3 , the threaded teeth are wound on the grinding shaft; inside the seal ring, a plurality of annular seal gears are arranged at intervals along its axial direction; the outer tooth edges of each annular seal gear They all correspond to the positions of the tooth bottoms of the thread teeth, and a rotation gap 62 is provided between the outer tooth edges and the tooth bottoms. When the steam passes through the gap, because the channel area becomes smaller, the flow velocity becomes faster and the pressure decreases under the effect of throttling. In the subsequent steam chamber, due to the expansion of the space, a strong eddy current is formed, the speed is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com