Preparation method of antiseptic composited wood

A technology of recombining wood and preservatives, which is applied in the field of wood manufacturing, can solve the problems of reducing wood material and service life, and achieve the effects of improving anti-corrosion performance, facilitating penetration and adsorption, and easy penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

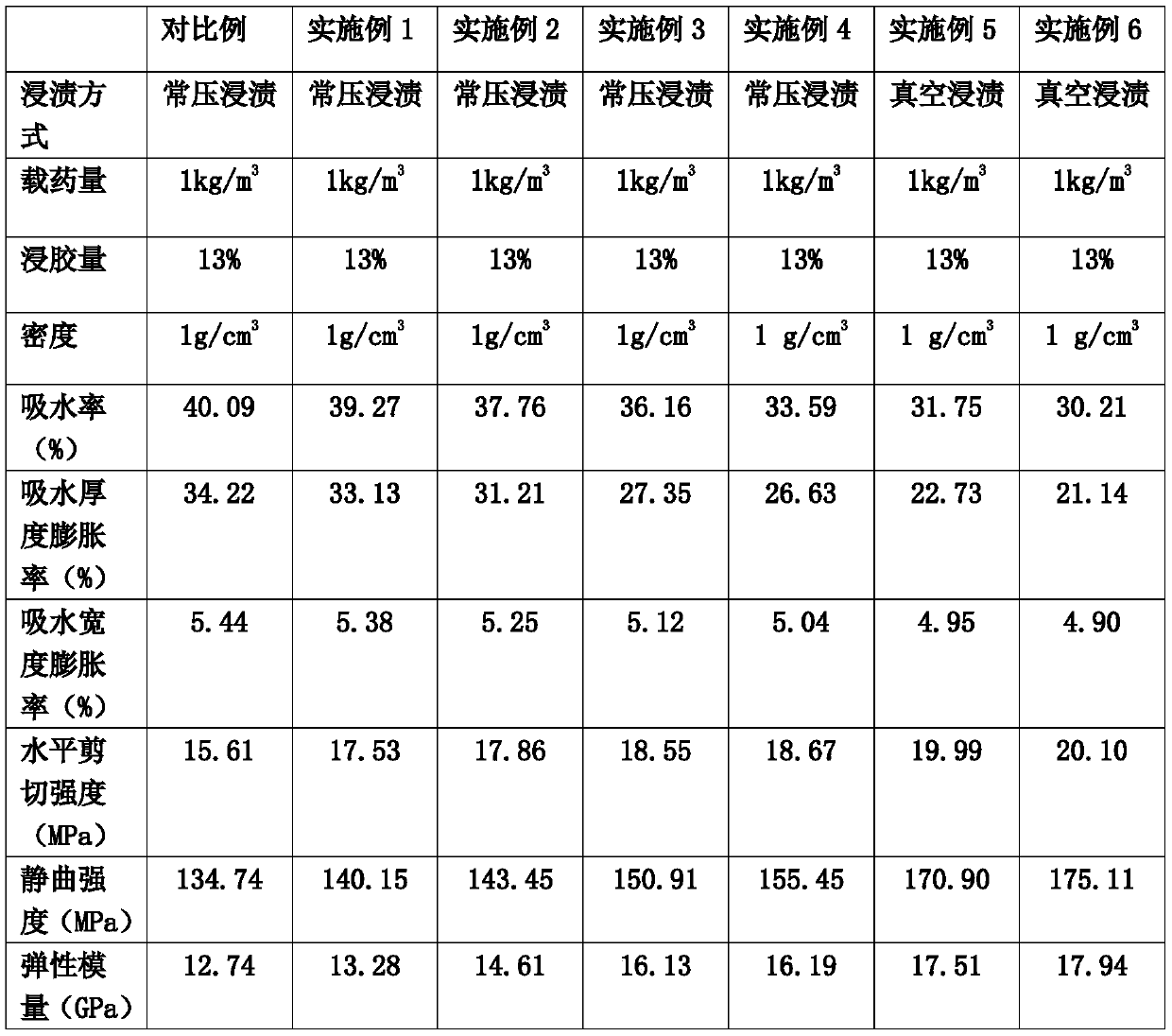

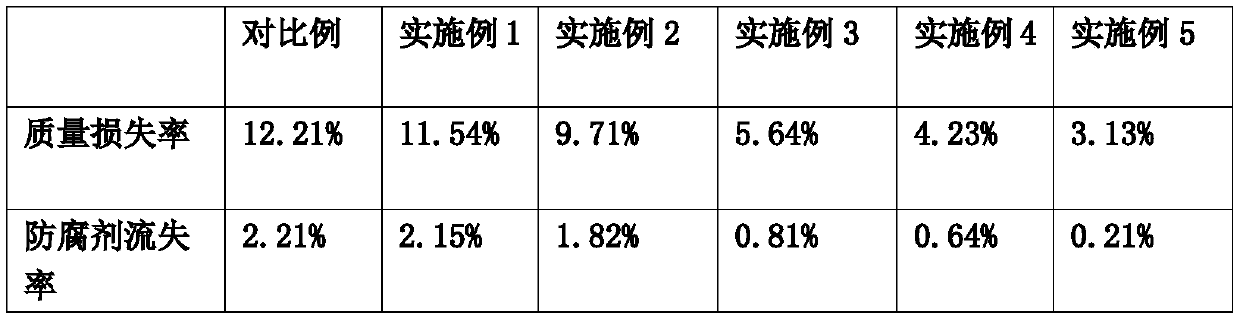

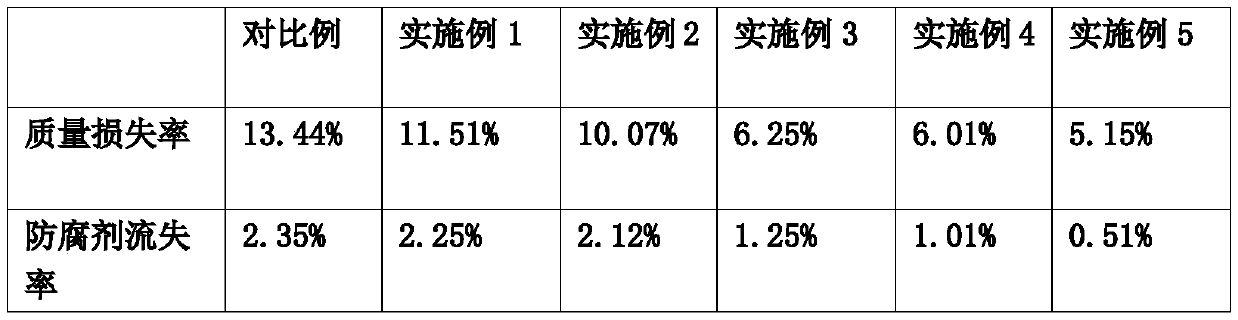

Examples

Embodiment 1

[0030] Embodiment 1: a kind of preparation method of anticorrosion recombined wood is carried out according to the following steps:

[0031] a. Wood (fast-growing poplar (P. × canadensis Moench): collected from Wen'an County, Hebei Province, 20 years old, diameter at breast height 25-35cm, air-dry density 0.33g / cm2 with rotary cutter 3 ) into veneers with a thickness of 7mm, and cut them, and then use a deflagging machine to decompose the veneers into long, cross-linked and network-like wood bundles that maintain the original arrangement of fibers, and dry to a moisture content of 9 %;

[0032] b. Immerse the wooden bundles in a copper azole preservative with a concentration of 0.25% to a drug loading of 1kg / m 3 , air-dried to a moisture content of 8% after impregnation;

[0033] c. Put the air-dried wood bundles into phenolic resin adhesive (solid content 48.06%, viscosity 72mPa·s (30°C)) for dipping, the dipping amount is 13% of the wood bundle mass fraction, after dipping...

Embodiment 2

[0035] Embodiment 2: a kind of preparation method of anticorrosion recombined wood is carried out according to the following steps:

[0036] a. Wood (fast-growing poplar (P. × canadensis Moench): collected from Wen'an County, Hebei Province, 20 years old, diameter at breast height 25-35cm, air-dry density 0.33g / cm2 with rotary cutter 3 ) into veneers with a thickness of 6 mm, and cut them, and then use a deflagging machine to decompose the veneers into long, interlinked and network-like wood bundles that maintain the original arrangement of fibers, and dry to a moisture content of 8 %;

[0037] b. Immerse the wood bundles in a copper azole preservative with a concentration of 0.28% to a drug loading of 1kg / m 3 , air-dried to a moisture content of 7% after impregnation;

[0038] c. Put the air-dried wood bundles into phenolic resin adhesive (solid content 48.06%, viscosity 72mPa·s (30°C)) for dipping, the dipping amount is 13% of the wood bundle mass fraction, after dipping ...

Embodiment 3

[0040] Embodiment 3: a kind of preparation method of anticorrosion recombined wood is carried out according to the following steps:

[0041] a. Wood (fast-growing poplar (P. × canadensis Moench): collected from Wen'an County, Hebei Province, 20 years old, diameter at breast height 25-35cm, air-dry density 0.33g / cm2 with rotary cutter 3 ) into veneers with a thickness of 5 mm, and cut them, and then use a deflagging machine to decompose the veneers into long, interlinked and network-like wood bundles that maintain the original arrangement of fibers, and dry to a moisture content of 7 %;

[0042] b. According to 21 parts of copper acetate, 55 parts of monoethanolamine, 10 parts of ammonia, 0.4 part of alcohol, 0.4 part of propiconazole, 5 parts of xylene, 3 parts of alkyl aryl polyoxyethylene ether, 40 parts of water are prepared according to conventional method to obtain copper azole preservative (the preparation of copper azole preservative is also can be used first Dissol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com