Bulk-phase super-hydrophobic nanofiber membrane for membrane distillation and preparation method of bulk-phase super-hydrophobic nanofiber membrane

A nanofiber membrane and nanofiber technology, applied in the field of bulk superhydrophobic nanofiber membranes for membrane distillation and its preparation, can solve the problem of small porosity, low permeation flux, and difficulty in long-term stable operation of microporous hydrophobic membranes. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

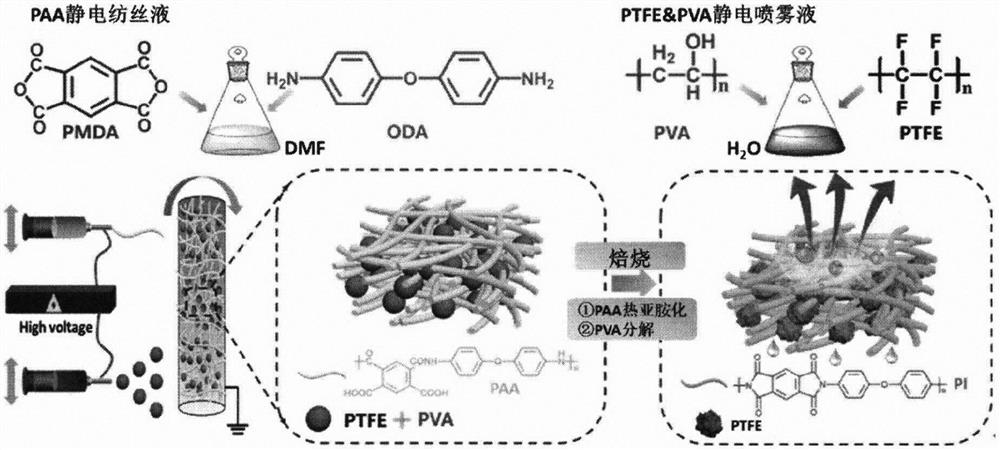

[0025] (1) Electrospinning solution preparation: PMDA and ODA with a molar ratio of 1:1 were dissolved in DMF, and a PAA electrospinning solution with a concentration range of 28 wt% was prepared by mechanical or magnetic stirring.

[0026] (2) Preparation of electrostatic spray liquid: blend the PTFE aqueous emulsion with a mass fraction of 60 wt% and a PVA aqueous solution with a mass fraction of 10 wt% at a mass ratio of 15:1, add 3 g of deionized water, and prepare by mechanical or magnetic stirring. PTFE & PVA electrostatic spray solution.

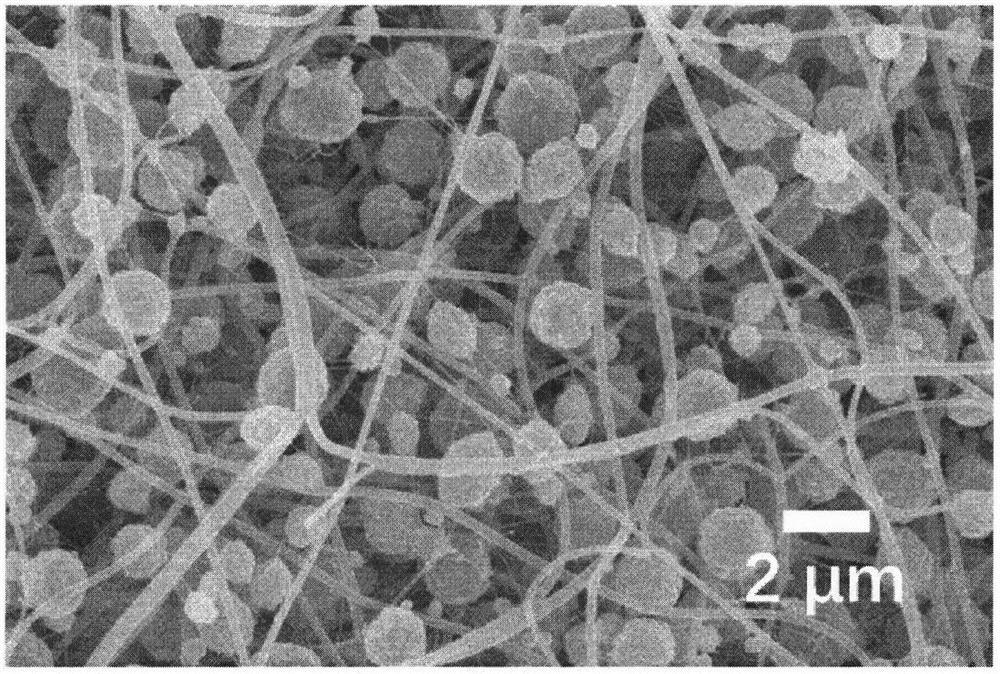

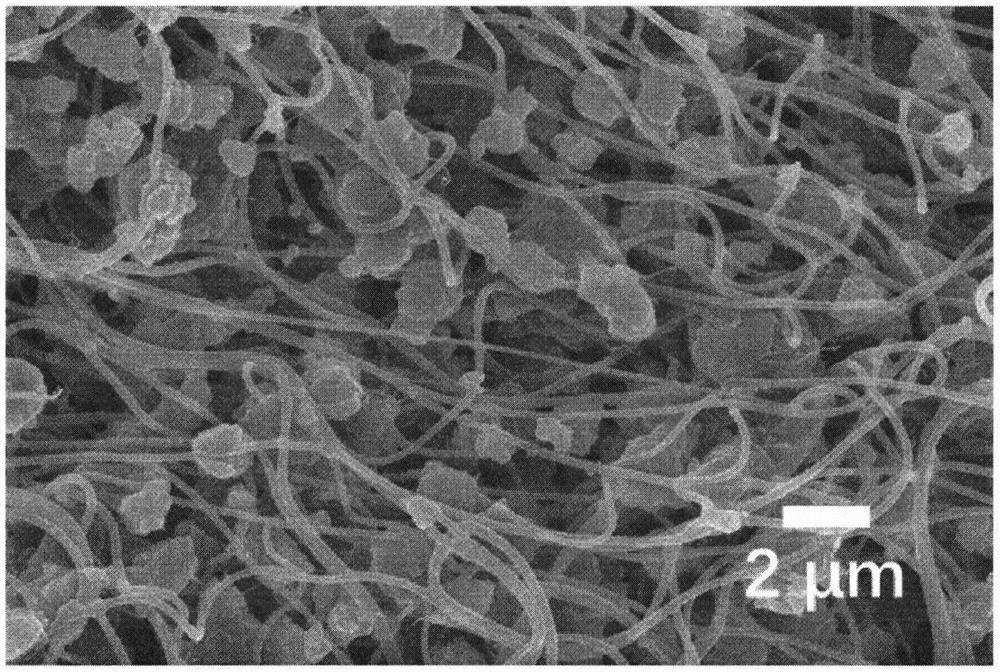

[0027](3) Synchronous electrospinning-electrostatic spraying process: transfer the above two prepared solutions to different syringes, and control the amount of PTFE&PVA electrostatic spraying solution and PAA electrospinning solution by changing the number of syringes filled with different solutions. The volume ratio is 2 / 1, and it is spun under spinning parameters (liquid supply rate 1.0ml / h, voltage 30kV, receiving distance 18cm, s...

Embodiment 2

[0037] (1) Electrospinning solution preparation: PMDA and ODA with a molar ratio of 1:1 were dissolved in DMF, and a PAA electrospinning solution with a concentration range of 26 wt% was prepared by mechanical or magnetic stirring.

[0038] (2) Preparation of electrostatic spray liquid: blend the PTFE aqueous emulsion with a mass fraction of 60 wt% and a PVA aqueous solution with a mass fraction of 10 wt% at a mass ratio of 12:1, add 2 g of deionized water, and prepare by mechanical or magnetic stirring. PTFE & PVA electrostatic spray solution.

[0039] (3) Synchronous electrospinning-electrostatic spraying process: transfer the above two prepared solutions to different syringes, and control the amount of PTFE&PVA electrostatic spraying solution and PAA electrospinning solution by changing the number of syringes filled with different solutions. The volume ratio is 1 / 1, and it is spun under spinning parameters (liquid supply rate 1.2ml / h, voltage 35kV, receiving distance 20cm, ...

Embodiment 3

[0044] (1) Electrospinning solution preparation: PMDA and ODA with a molar ratio of 1:1 were dissolved in DMF, and a PAA electrospinning solution with a concentration range of 24 wt% was prepared by mechanical or magnetic stirring.

[0045] (2) Preparation of electrostatic spray liquid: blend the PTFE aqueous emulsion with a mass fraction of 60 wt% and a PVA aqueous solution with a mass fraction of 10 wt% in a mass ratio of 18:1, add 5 g of deionized water, and prepare by mechanical or magnetic stirring. PTFE & PVA electrostatic spray solution.

[0046] (3) Synchronous electrospinning-electrostatic spraying process: transfer the above two prepared solutions to different syringes, and control the amount of PTFE&PVA electrostatic spraying solution and PAA electrospinning solution by changing the number of syringes filled with different solutions. The volume ratio is 1 / 2, and it is spun under the spinning parameters (liquid supply rate 0.8ml / h, voltage 30kV, receiving distance 15...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com