Preparation system of compound type bamboo fiberboards and preparation method of compound type bamboo fiberboards

A preparation system and bamboo fiber technology, applied in flat products, manufacturing tools, mechanical equipment, etc., can solve the problems of high production consumption and power consumption, high cost, low production efficiency, etc., and achieve high production rate and good product quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

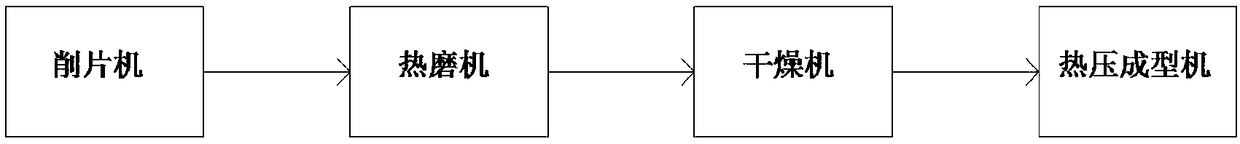

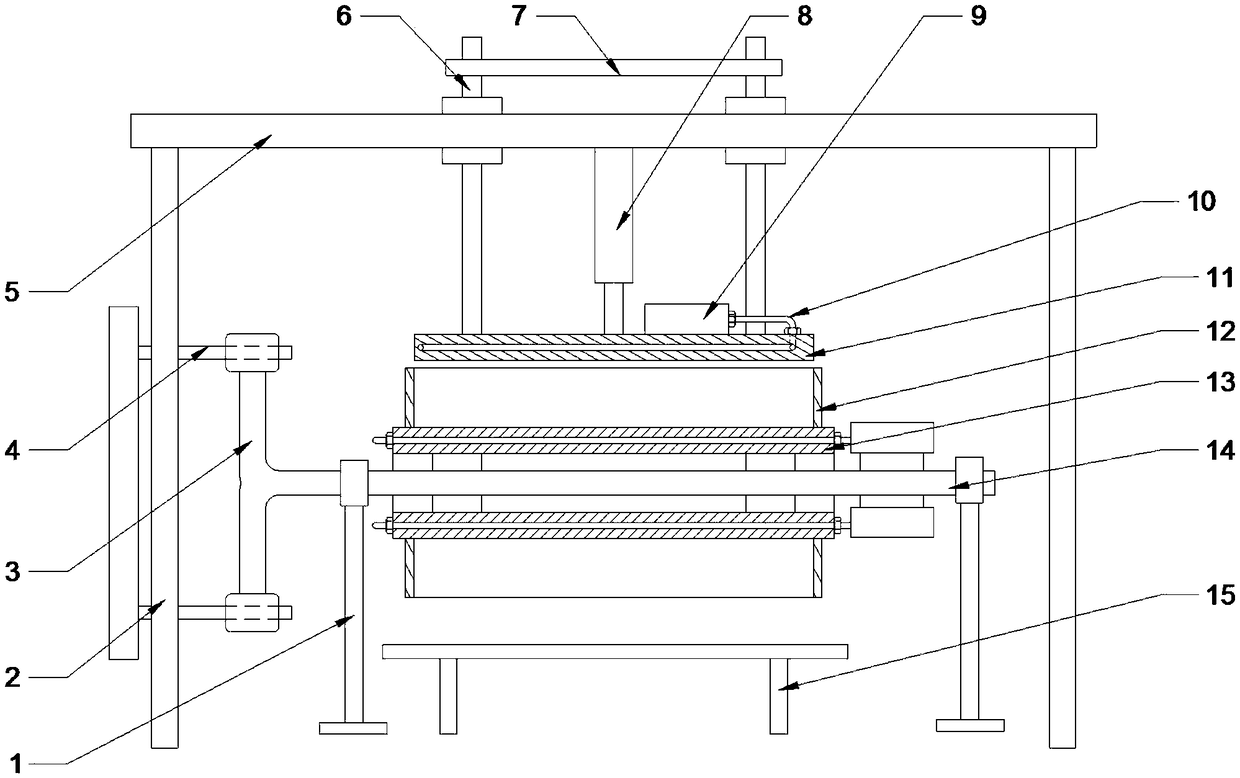

[0031] see Figure 1~2 , a composite bamboo fiber board preparation system, including a chipper, a thermal grinder, a dryer, a hot press forming machine, a hot press forming machine including a hydraulic rod 8, a hot pressing mold 12, a heat transfer oil heating device 9, and a heat transfer oil conduit 10. Pressing plate 11, top plate 13, the thermocompression molding machine also includes a shaft support 1, a rotating shaft 14 is also installed on the shaft support 1, and the top plate 13 is arranged on the rotating shaft 14 in a circular array around the axis of the rotating shaft 14. Press mold 12, hot press mold 12 is a rectangular box without top cover and bottom cover, its bottom opening and top plate 13 facing away from the one side of rotating shaft 14 butt joint, hydraulic rod 8 is installed on the crossbeam 5, and crossbeam 5 is installed on On the support column 2, the head of the hydraulic rod 8 telescopic rod is connected with the pressure plate 11, the pressure ...

Embodiment 2

[0034] see Figure 1~2 , a composite bamboo fiber board preparation system, including a chipper, a thermal grinder, a dryer, a hot press forming machine, a hot press forming machine including a hydraulic rod 8, a hot pressing mold 12, a heat transfer oil heating device 9, and a heat transfer oil conduit 10. Pressing plate 11, top plate 13, the thermocompression molding machine also includes a shaft support 1, a rotating shaft 14 is also installed on the shaft support 1, and the top plate 13 is arranged on the rotating shaft 14 in a circular array around the axis of the rotating shaft 14. Press mold 12, hot press mold 12 is a rectangular box without top cover and bottom cover, its bottom opening and top plate 13 facing away from the one side of rotating shaft 14 butt joint, hydraulic rod 8 is installed on the crossbeam 5, and crossbeam 5 is installed on On the support column 2, the head of the hydraulic rod 8 telescopic rod is connected with the pressure plate 11, the pressure ...

Embodiment 3

[0038] see Figure 1~2 , a composite bamboo fiber board preparation system, including a chipper, a thermal grinder, a dryer, a hot press forming machine, a hot press forming machine including a hydraulic rod 8, a hot pressing mold 12, a heat transfer oil heating device 9, and a heat transfer oil conduit 10. Pressing plate 11, top plate 13, the thermocompression molding machine also includes a shaft support 1, a rotating shaft 14 is also installed on the shaft support 1, and the top plate 13 is arranged on the rotating shaft 14 in a circular array around the axis of the rotating shaft 14. Press mold 12, hot press mold 12 is a rectangular box without top cover and bottom cover, its bottom opening and top plate 13 facing away from the one side of rotating shaft 14 butt joint, hydraulic rod 8 is installed on the crossbeam 5, and crossbeam 5 is installed on On the support column 2, the head of the hydraulic rod 8 telescopic rod is connected with the pressure plate 11, the pressure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com