Phosphate radical ion recycling method for activated carbon washes with method of phosphoric acid

A phosphate ion and recovery method technology, which is applied in the field of phosphate ion recovery from phosphoric acid method activated carbon washing wastewater, can solve the problems of high transportation and treatment costs, low solid content of calcium phosphate mixture, etc., achieves low production cost and is easy to promote industrialization , easy-to-achieve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

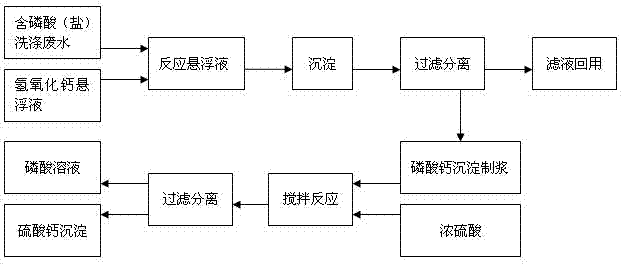

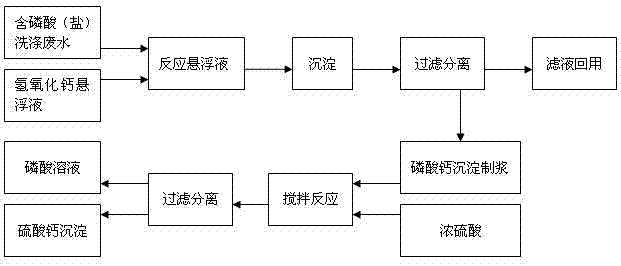

Method used

Image

Examples

Embodiment 1

[0020] Use 20% calcium hydroxide emulsion to react with production wastewater containing phosphoric acid 2000g / ml, the reaction pH is 9.5, the calcium phosphate sludge after reaction precipitation is filtered, and the filtrate is used as the washing of phosphoric acid activated carbon, and the formed solid content is 30% The calcium phosphate filter cake is made into a slurry, and calcium phosphate (dry basis) and 98% concentrated sulfuric acid are added dropwise at a mass ratio of 0.8:1. After the reaction is complete, filter and separate, the reclaimed phosphoric acid filtrate has a phosphoric acid content of 8%, and the recovery rate of phosphoric acid is 95%.

Embodiment 2

[0022] Use 20% calcium hydroxide emulsion to react with phosphoric acid 1000g / ml production wastewater, the reaction pH9, the calcium phosphate sludge after the reaction precipitation is filtered to form calcium phosphate filter cake, and the filtrate is used as the washing of phosphoric acid activated carbon to form 40 % calcium phosphate filter cake to make a slurry, calcium phosphate (dry basis) and 98% concentrated sulfuric acid are added dropwise at a mass ratio of 1.2:1. After the reaction is complete, filter and separate, the phosphoric acid filtrate phosphoric acid content of recovery is 14%, and the recovery rate of phosphoric acid is 93%.

Embodiment 3

[0024] Use 20% calcium hydroxide emulsion to react with production wastewater containing phosphoric acid 6000g / ml, the reaction pH is 10, the calcium phosphate sludge after reaction precipitation is filtered to form calcium phosphate filter cake, and the filtrate is used as the washing of phosphoric acid activated carbon to form 35 % calcium phosphate filter cake to make a slurry, calcium phosphate (dry basis) and 98% concentrated sulfuric acid are added dropwise at a mass ratio of 1:1. After the reaction is complete, filter and separate, the reclaimed phosphoric acid filtrate has a phosphoric acid content of 10%, and the recovery rate of phosphoric acid is 93%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com