Automatic circulating water descaling system for hot-rolled rod and wire steel

A technology of automatic circulation and descaling system, which is applied in metal rolling, metal rolling, metal processing equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

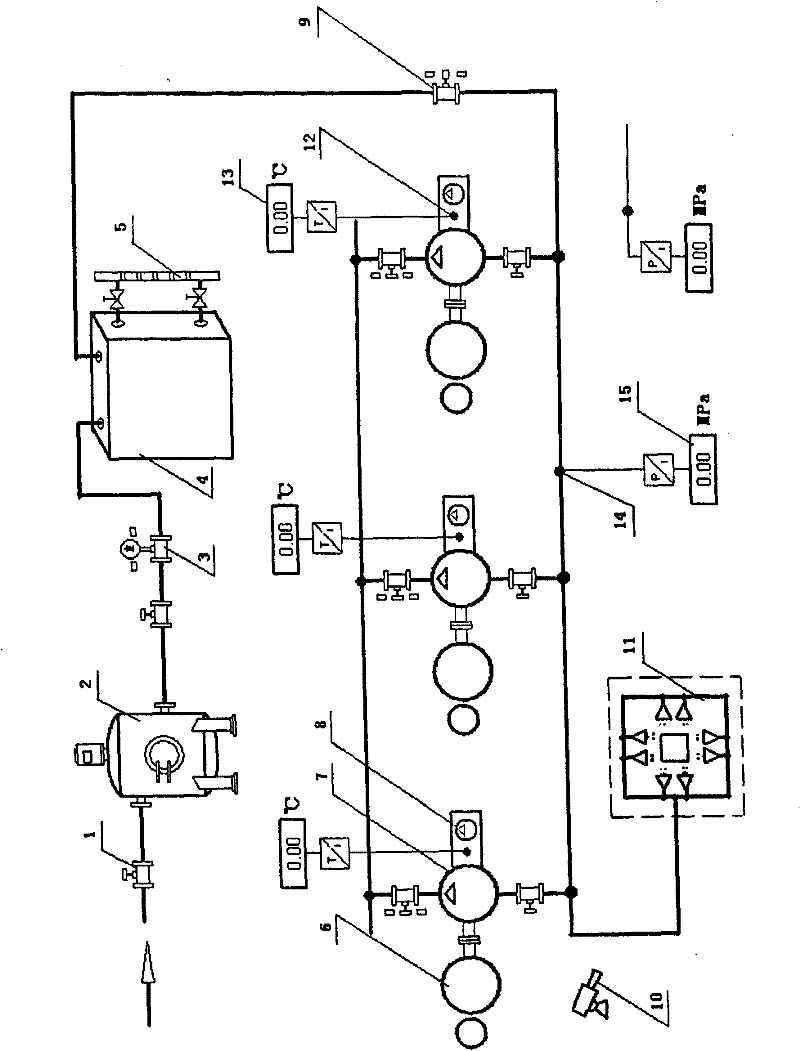

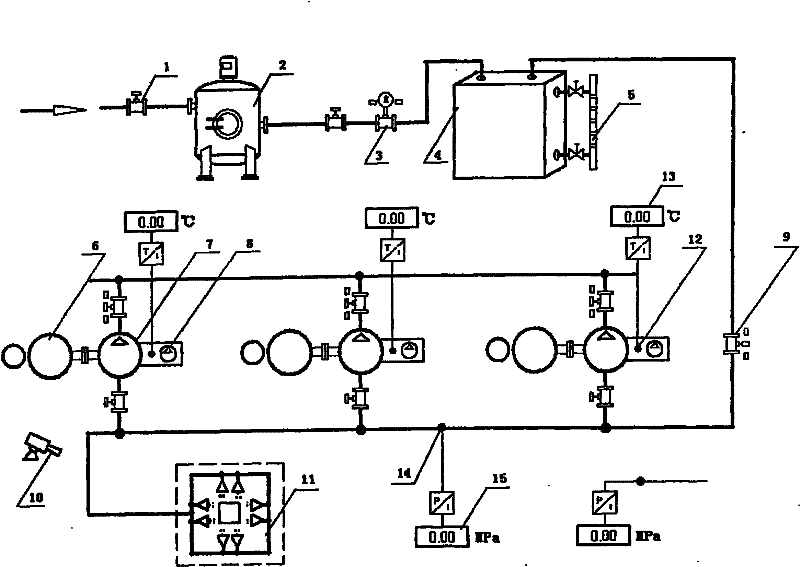

[0008] The structure of the present invention is shown in the accompanying drawings: it is composed of an automatic backwashing water filter, a high-level water tank, a pneumatic jet valve, a plunger pump descaling box and an electric control cabinet. There is an automatic backwashing water filter 2 on the water supply pipeline. An elevated water tank 4 is arranged on the outlet side of the automatic backwashing water filter. An electric water feed valve 3 is arranged on the pipeline between the backwash water filter and the high level water tank. There is a manual butterfly valve 1 on the water supply line of the automatic backwashing water filter. There is a magnetic float liquid level gauge 5 on the high level water tank. A plunger pump 7 is provided on the outlet pipe at the lower part of the elevated water tank. The plunger pump is equipped with a low-voltage variable frequency motor 6 and a self-lubricating gear pump 8 . The plunger pump, low-voltage frequency conver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com