Device for recycling silicon wafer cleaning wastewater

A silicon wafer cleaning and wastewater technology, which is applied to cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc., can solve the problems of less than 10% wastewater reuse rate, increase the manufacturing cost of cleaning machines, etc., and achieve savings. The effect of equipment cost, production cost saving and wastewater discharge reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

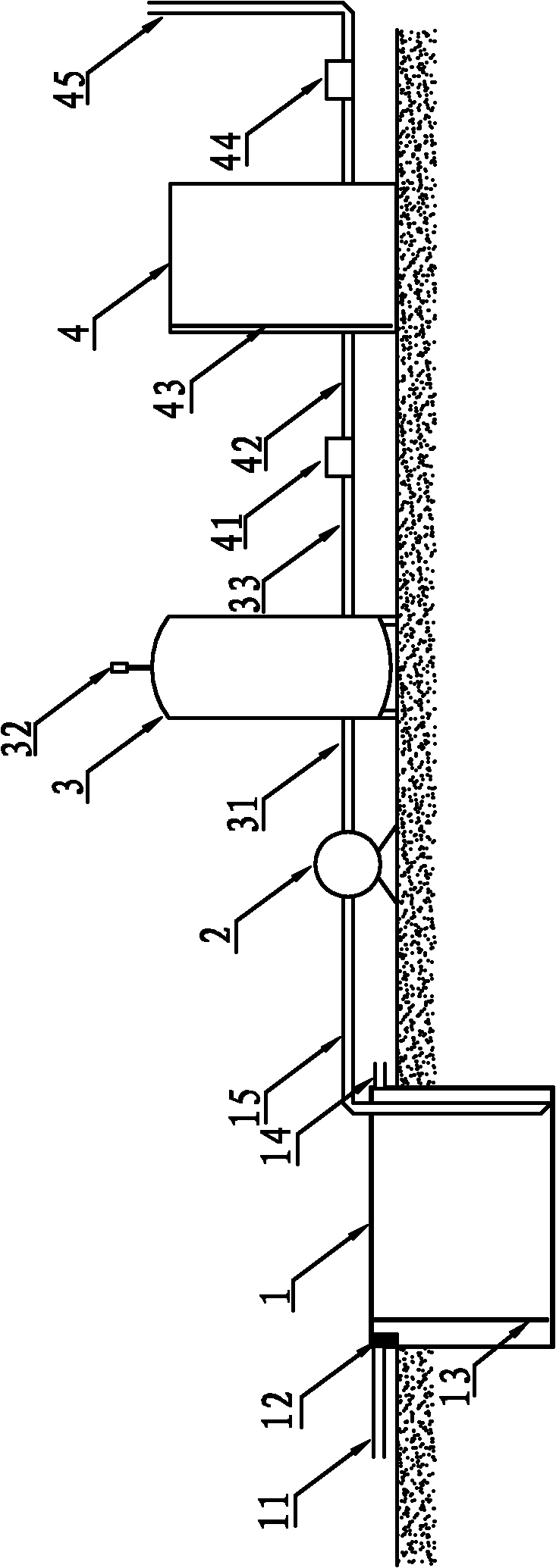

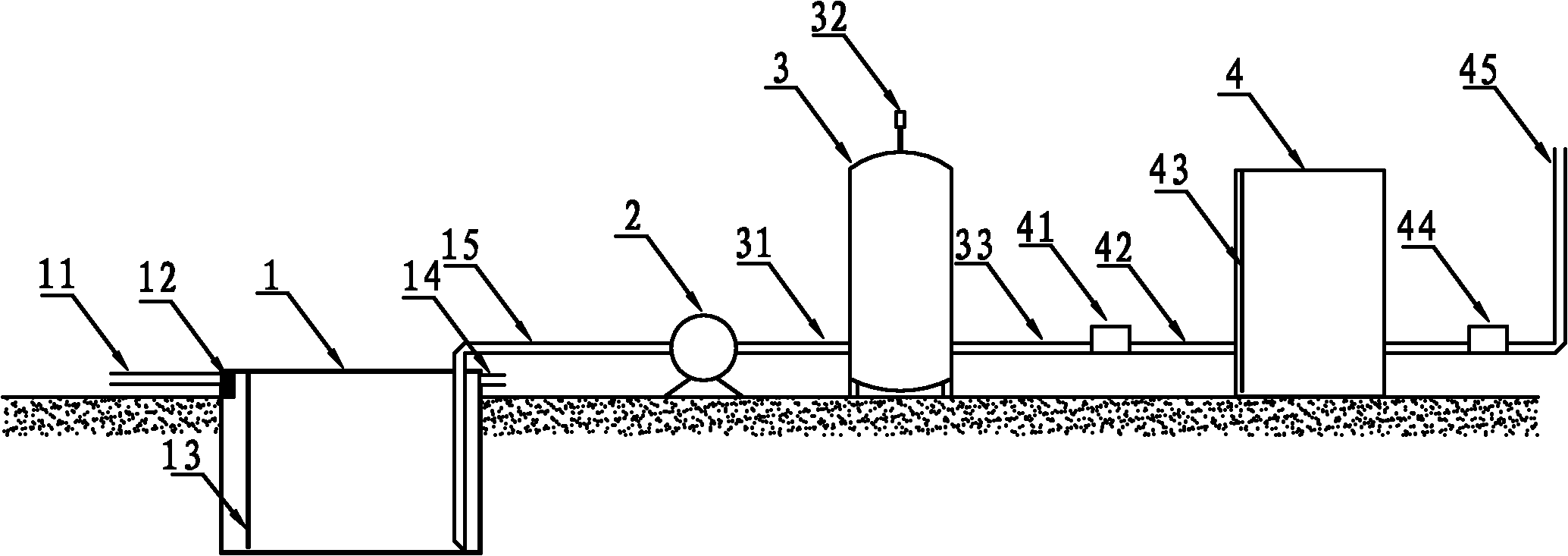

[0011] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0012] figure 1 Among them, including the reuse water storage tank 1, the reuse water inlet pipe 11, the filter screen 12, the first liquid level sensor 13, the overflow port 14, the suction pipe 15, the booster pump 2, the pressure water tank 3, the pressure water tank inlet Water pipe 31, pressure sensor 32, pressure water tank outlet pipe 33, degumming machine water storage tank 4, first solenoid valve 41, recycled water replenishment pipe 42, second liquid level sensor 43, second solenoid valve 44, tap water replenishment pipe 45, etc. .

[0013] Such as figure 1 As shown, the present invention is a silicon wafer cleaning waste water recycling device, including a reuse water storage tank 1, a booster pump 2, a pressure water tank 3 and a degumming machine storage tank 4.

[0014] The reuse water storage tank 1 is lower than the ground...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com