Oxidation prevention process used for lithium ion battery copper foil

A lithium-ion battery and anti-oxidation technology, which is applied in the coating process of metal materials, etc., can solve the problems of difficult control, many transition rolls, and poor wettability of copper foil surface, so as to reduce production water and save production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

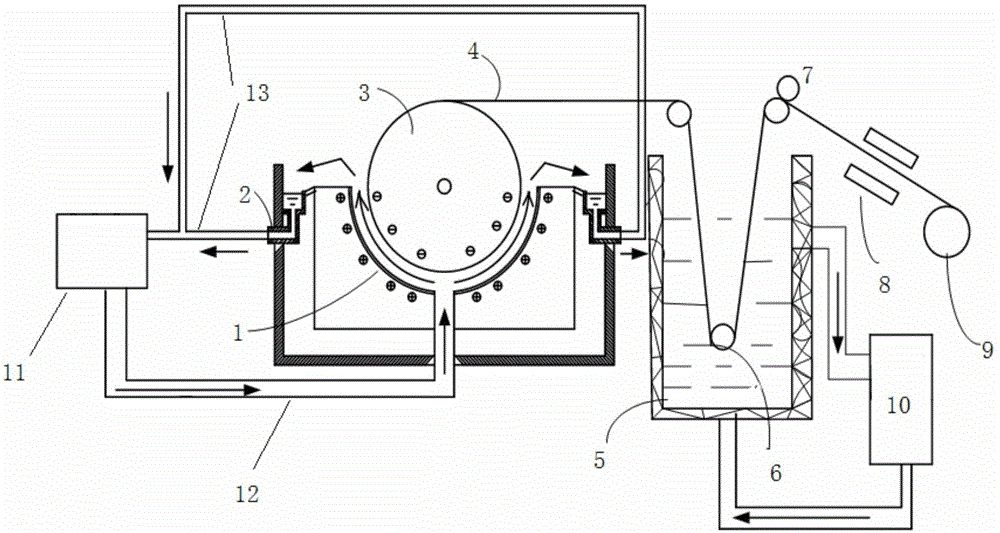

[0026] refer to figure 1 , through the lithium battery foil integrated machine, the lithium battery foil semi-finished copper foil produced according to the patent (patent number: CN201110230192.1) process formula of "Preparation of Double-sided Photoelectrolytic Copper Foil for Special Lithium Batteries" is pulled through the anti-oxidation tank and prepared The anti-oxidation passivation solution is used to chemically coat the anti-oxidation layer, and then it is squeezed dry and directly enters the oven for drying and winding.

[0027] In anti-oxidation solution, benzotriazole 150g / m 3 , chromic anhydride 200g / m 3 , cerium phosphate 1.0g / m 3 , Vinyltriethoxysilane 1.0g / m 3 , ethanol 20L / m 3 , the temperature is 40°C, and the pH value is adjusted to 6.5 with sodium hydroxide.

[0028] This anti-oxidation solution is introduced into the anti-oxidation tank in the lithium battery foil integrated machine equipment, and will be produced according to the patent (patent numbe...

Embodiment 2

[0031] Carry out anti-oxidation treatment of copper foil with reference to the preparation method of Example 1, the anti-oxidation solution of each unit is made up of the raw material with following ratio: benzotriazole 150g / m 3 , chromic anhydride 500g / m 3 , lanthanum phosphate 1.5g / m 3 , phenyltriethoxysilane 1.0g / m 3 , ethanol 20L / m 3 , the temperature is 40°C, and the pH value is adjusted to 6.5 with sodium hydroxide.

[0032] The rough surface of the lithium battery copper foil prepared in this example is mirror-like like the smooth surface, and the surface is smooth and wrinkle-free. After testing, the wettability of the lithium battery copper foil is ≥40×10 -3 N / m (characterized by surface tension parameters), mass resistivity 0.160Ω·g / m 2 , The anti-oxidation film is uniform, does not change color and does not have any oxidation points under the condition of 140°C, 15min oven, and the copper foil slightly changes color under the condition of 160°C, 10min oven.

[00...

Embodiment 3

[0035] Carry out anti-oxidation treatment of copper foil with reference to the preparation method of Example 1, the anti-oxidation solution of each unit is made up of the raw material with following ratio: benzotriazole 150g / m 3 , chromic anhydride 500g / m 3 , yttrium phosphate 1.2g / m 3 , γ-glycidyl propyl-trimethoxysilane 1.0g / m 3 , ethanol 20L / m 3 , the temperature is 40°C, and the pH value is adjusted to 6.5 with sodium hydroxide.

[0036] The rough surface of the lithium battery copper foil prepared in this example is mirror-like like the smooth surface, and the surface is smooth and wrinkle-free. After testing, the wettability of the lithium battery copper foil is ≥40×10-3N / m (characterized by surface tension parameters) , the mass resistivity is 0.162Ω·g / m 2 , The anti-oxidation film is uniform, does not change color and does not have any oxidation points under the condition of 140°C, 15min oven, and the copper foil slightly changes color under the condition of 160°C,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wettability | aaaaa | aaaaa |

| wettability | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com