Hot stretch forming method for shunt shell

A shunt and thermal stretching technology, which is applied in the field of aero-engine shunt processing, can solve problems such as the difficulty in forming the titanium alloy shunt shell 1, and achieve the effect of reducing material thickness, ensuring processing quality, and good strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

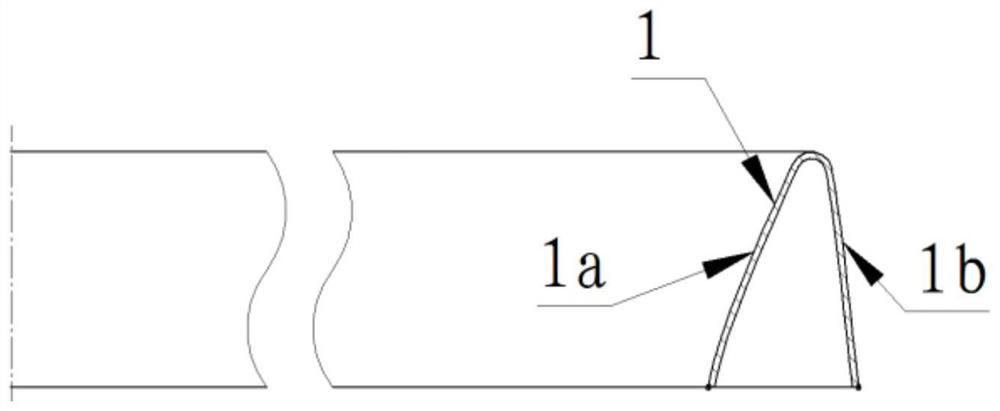

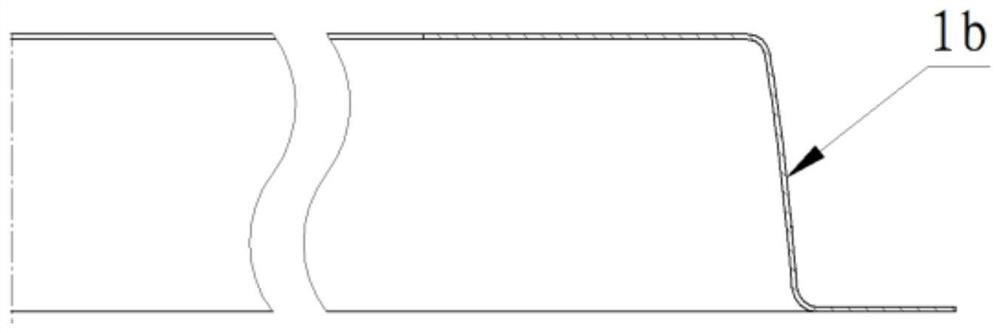

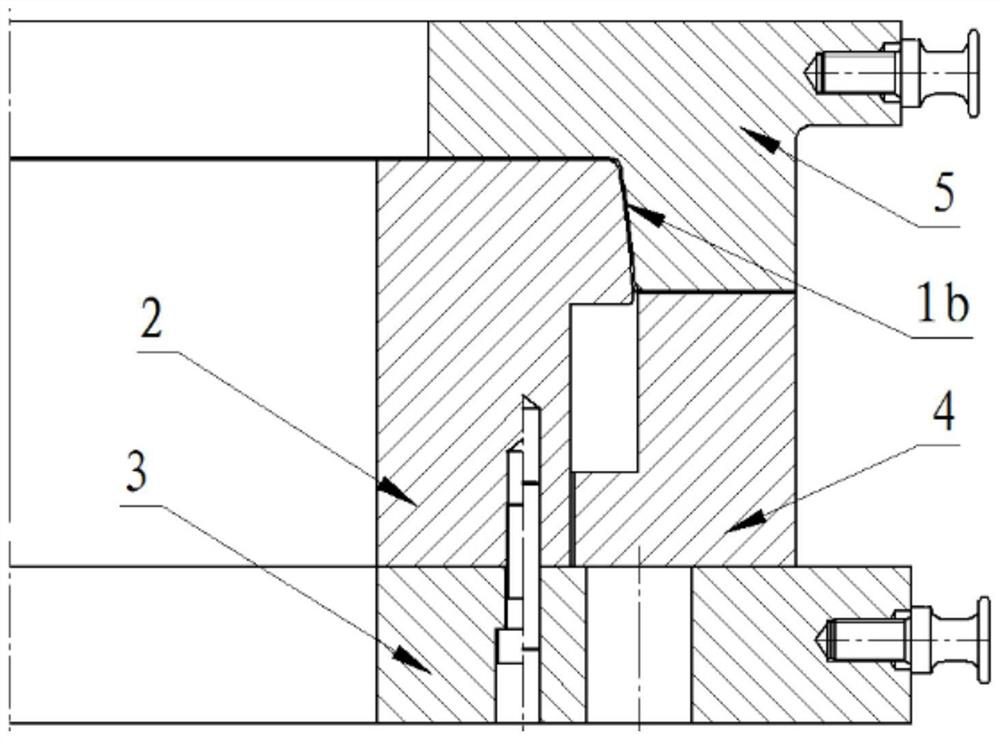

[0027] Such as Figure 1 to Figure 5 As shown, in the hot stretch forming method of a shunt casing according to the present invention, the shunt casing 1 is an annular titanium alloy sheet metal part with a V-shaped cross section, and its wall thickness is t. The shunt casing 1 includes, including an inner ring plate 1a and an outer ring plate 1b, the junction of the outer ring plate 1b and the inner ring plate 1a adopts a smooth transition of a circular arc, and the hot stretch forming method of the diverter shell 1 includes the following steps:

[0028] A. Blanking: use TC1 plate blanking to make circular wool. When in use, calculate the size of the ring-shaped wool according to the expanded size and machining allowance of the shunt housing 1 .

[0029] B. The first thermal stretch forming: under the cooperation of the thermal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com