Formwork cloth for buildings and method for preparing formwork cloth

A technology for template cloth and construction, which is applied to building elements, non-woven fabrics, textiles and paper making, etc. It can solve the problems of lack of implementation operability of patents, difficult to clean the surface of template cloth, complicated preparation process, etc., so as to improve the appearance. Effect of quality, easy demoulding, enhanced strength and surface smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] A method for preparing template cloth for construction, comprising:

[0052] Step 101, the fiber raw material is prepared through the preparation process of feeding cotton by weighing, secondary opening, cotton feeding by air pressure box, carding air-laid, acupuncture reinforcement, slitting and winding, and the fiber raw material is PP fine denier fibers, PP coarse denier fibers and PP / PE low-melting bicomponent fibers, wherein the PP fine denier fibers and the PP coarse denier fibers have a fineness of 3-11D and a length of 51-65mm, The PP / PE low melting point bicomponent fiber has a fineness of 1.5-3D and a length of 38-51mm. The PP fine denier fiber, the PP coarse denier fiber and the PP / PE low melting point bicomponent fiber are three The mixing ratio of the latter is 30-40:40-60:10-20.

[0053] Step 102, preparing a film foaming solution.

[0054] Step 103, unwinding the base fabric and transporting it to the coating machine, sending the coating film foaming li...

Embodiment 2

[0059] Step 201, the fiber raw material is prepared through the preparation process of weighing and feeding cotton, secondary opening, feeding cotton by air pressure box, carding air-laid, acupuncture reinforcement, slitting and winding, and the fiber raw material is PP fine denier fibers, PP coarse denier fibers and PP / PE low-melting bicomponent fibers, wherein the PP fine denier fibers and the PP coarse denier fibers have a fineness of 3-11D and a length of 51-65mm, The PP / PE low melting point bicomponent fiber has a fineness of 1.5-3D and a length of 38-51mm. The PP fine denier fiber, the PP coarse denier fiber and the PP / PE low melting point bicomponent fiber are three The mixing ratio of the latter is 30-40:40-60:10-20.

[0060] As a further improvement of the present invention, in the process of weighing and feeding cotton, the rotation speed of the batter is 165-190r / min, and the speed of the brad nail cord is 6.9-14.4m / min.

[0061] In the secondary opening process, t...

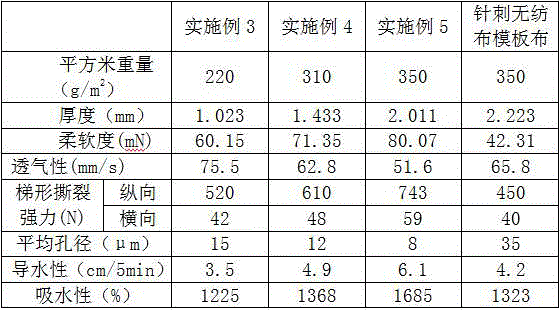

Embodiment 3

[0078] 1) Preparation of base cloth

[0079] The fineness of PP fine denier fiber is 3D and the length is 51mm, the fineness of PP coarse denier fiber is 9D and the length is 65mm, the fineness of PP / PE low melting point bicomponent fiber is 1.5D and the length is 38mm, and the fineness of PP fine denier fiber is 9D and the length is 65mm. The mixing ratio of denier, coarse denier and PP / PE is 30:60:10, and the surface oil content of PP fine denier fiber, PP coarse denier fiber and PP / PE low-melting bicomponent fiber is 0.85%;

[0080] The main preparation process parameters are as follows: in the process of weighing and feeding cotton, the rotation speed of the beater is 165r / min, and the speed of the corner nail cord is 6.9m / min; , the beater speed of the sawtooth drum cotton opener is 650r / min; in the cotton feeding process of the air pressure cotton box, the speed of the beater is controlled to be between 350r / min and the speed of the cotton output roller is 14r / min. The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com