LCP (Liquid Crystal Polymer) film as well as preparation method and application thereof

A film and film bubble technology, applied in the field of LCP film and its preparation, can solve the problems of anisotropy of mechanical properties, poor film thickness uniformity, poor film bubble stability, etc., to solve the problems of poor film thickness uniformity, high surface quality, good isotropic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with specific embodiments. The following examples will help those skilled in the art to further understand the present invention, but do not limit the present invention in any form.

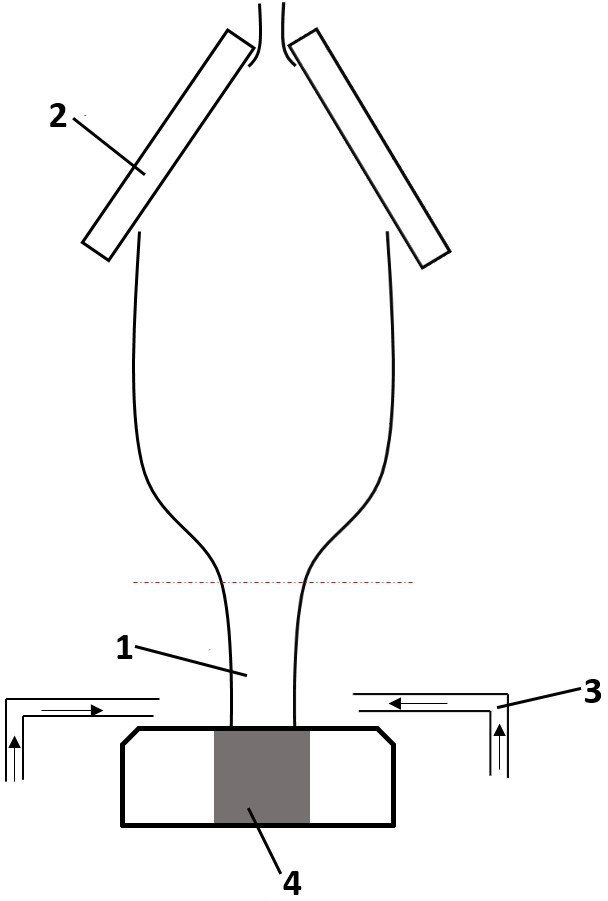

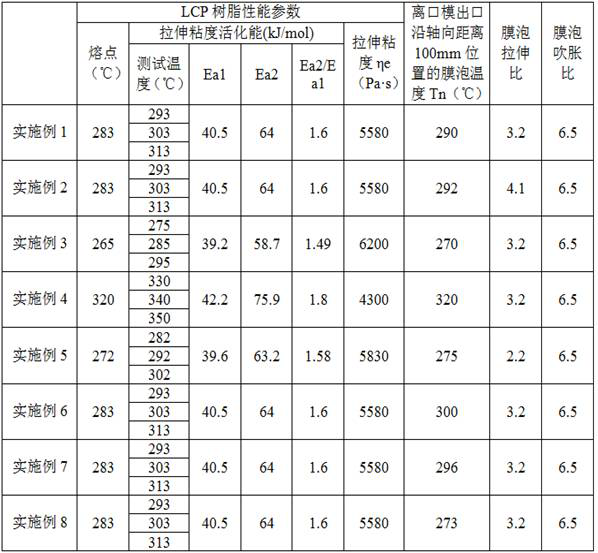

[0028] The preparation method of the LCP thin film of the embodiment of the present invention and comparative example: adopt as figure 1 In the equipment shown, the LCP resin is melted and plasticized by the extruder, extruded through the die 4 to form a bubble 1, and a gas medium is introduced into the bubble to inflate the bubble, cooled and shaped by the air ring 3, and the bubble reaches the human body. The letter plate 2 is flattened and flattened, and pulled out by a guide roller for winding and forming to obtain an LCP film. The physical parameters and LCP film blow molding conditions of the LCP resin used in each embodiment and comparative example are shown in Table 1 / Table 3.

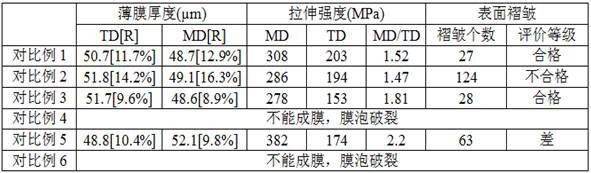

[0029] In the examples and comp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongational viscosity | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com