Method for treating waste gas from dimethylamine recovery by synthetic leather dimethyl formamide

A technology of dimethylformamide and dimethylamine, which is applied in the separation/purification of carboxylic acid amides, climate sustainability, sustainable manufacturing/processing, etc., can solve the problem of damaging surrounding air quality, affecting human health and polluting the environment and other issues, to achieve the effect of ensuring human health, significant social and economic benefits, and protecting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

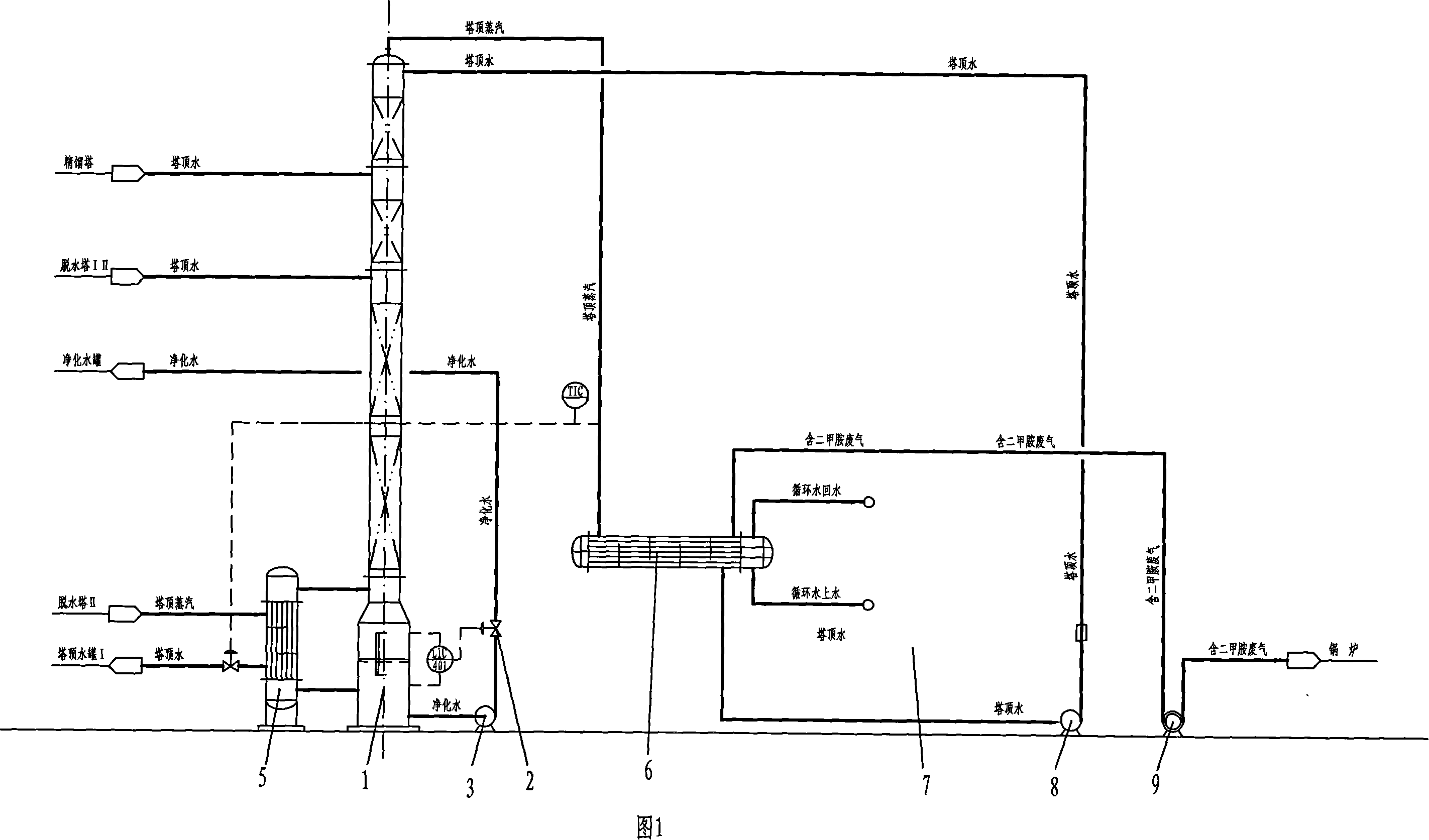

[0012] The present invention will be described in detail below in conjunction with accompanying drawing: As shown in the accompanying drawing, the present invention mainly comprises: preheating, deamination, drainage etc. constitute DMF recovery tower top water deamination process, wherein dehydration tower I, dehydration tower II tower top Water dimethylamine concentration is lower (about 200ppm), enters the middle section of deamination tower 1; A high-efficiency screen packing is installed in the amine tower 1, and the dimethylamine in the tower top water is taken away by the rising steam in the deamination tower 1. The purified water after removal of dimethylamine is collected in the tank of the deamination tower 1, controlled by the liquid level regulator 2, discharged by the deamination tower drainage pump 3, and sent to the purified water storage tank 4 for recycling in wet production.

[0013] The reboiler 5 of the deamination tower is heated by the steam at the top of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com