Method for maintaining freshness of materials of system for producing reconstituted tobaccos by paper-making process

A technology for reconstituted tobacco leaves and production systems, which is applied in the fields of tobacco, tobacco preparation, food science, etc., and can solve the problems of sensory quality of finished reconstituted tobacco leaves, no production system anticorrosion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

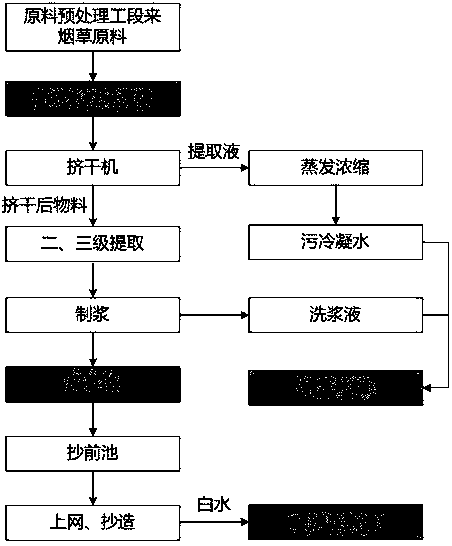

[0027] A method for maintaining the freshness of materials in a papermaking reconstituted tobacco leaf production system, such as figure 1 shown, including the following steps:

[0028] (1) The tobacco stem raw materials used for the production of reconstituted tobacco leaves by the papermaking method enter the stem washing process after the raw material pretreatment section, and are treated in hot water at 50°C for 5 minutes, and the solid and liquid are separated. The powder is mixed in a high-consistency hydraulic pulper to complete the primary water extraction; the primary water extraction concentration is 15% (that is, the solid content is 15wt%, the same below), the temperature is 70 ° C, and the time is 20min; At the same time of extraction, the primary extract was sterilized online under the condition of 700W by microwave sterilizer for 5 minutes in the high-concentration hydraulic pulper;

[0029] (2) The material after the first-level extraction that step (1) obtains ...

Embodiment 2

[0038] A method for maintaining the freshness of materials in a papermaking reconstituted tobacco leaf production system, such as figure 1 shown, including the following steps:

[0039] (1) The tobacco stem raw materials used in the production of reconstituted tobacco leaves by the papermaking method enter the stem washing process after the raw material pretreatment section, and are treated in hot water at 60°C for 3 minutes, and the solid and liquid are separated. The powder is mixed in a high-concentration hydraulic pulper to complete the primary water extraction; the primary water extraction concentration is 15% (that is, the solid content is 15wt%, the same below), the temperature is 70 ° C, and the time is 25min; At the same time of extraction, in the high-concentration hydraulic pulper, the primary extract was sterilized online for 5 minutes with a microwave sterilizer 700W;

[0040] (2) The material after the primary extraction obtained in step (1) is subjected to soli...

Embodiment 3

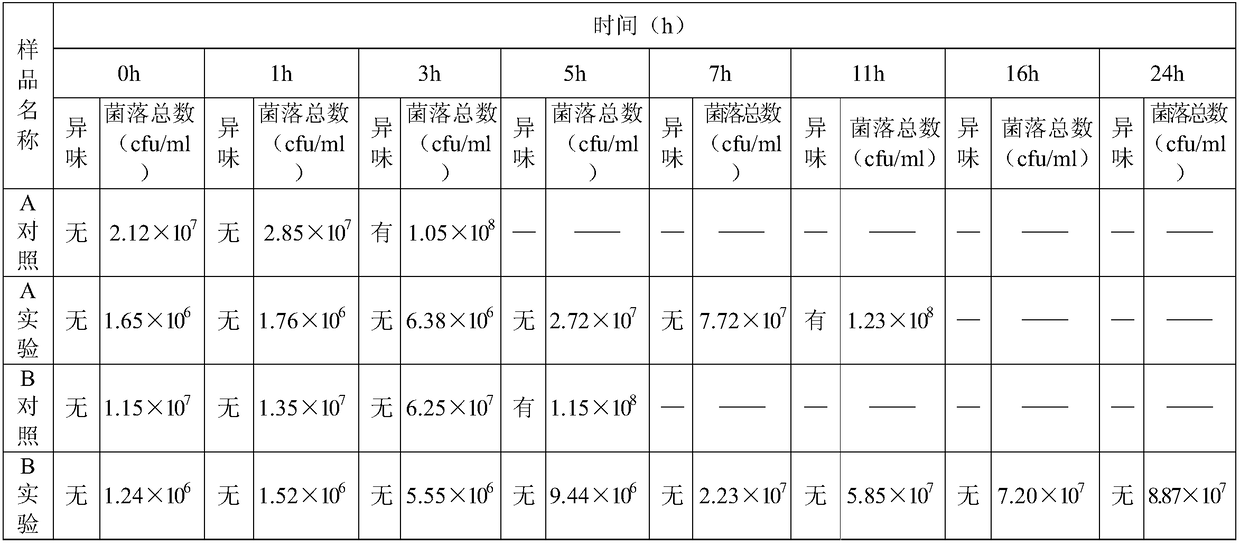

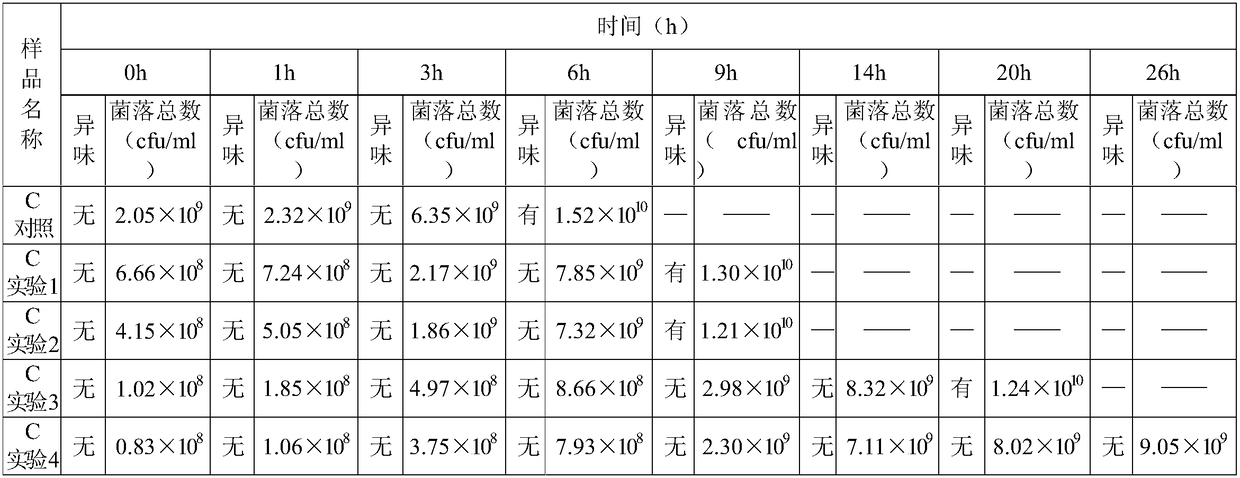

[0050] Take 1000g of the material in the high-consistency hydraulic pulper of the reconstituted tobacco production line of the papermaking method (that is, the primary extraction material, which is a mixture of reconstituted tobacco stems and tobacco powder) and divide it into 4 groups, each group 250g, put it in four 500ml extinguished Bacteria beakers, marked as A control, A experiment, B control, B experiment. Detect the initial total number of colonies in the A control sample, place the A experiment in a laboratory microwave sterilizer at a power of 700W, take it out after 5 minutes of treatment, detect the initial total number of colonies in the A test sample after the treatment, and compare the A control with the microwave The A test samples treated by the sterilizer were uniformly stirred at 30-40°C at room temperature (the stirring rotor was sterilized at high temperature); the B control and B experiments were heated to 70°C in a constant temperature water bath, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com