Innocent treatment method for mercury-containing waste tube

A technology for harmless treatment and lamp tubes, applied in defective lamp tubes/lamp repair/regeneration, lamp tube/lamp material recycling, electronic waste recycling, etc., can solve the third waste gas and wastewater treatment process complexity, sorting Solve the problems of mercury on metal and large amount of waste gas treatment, and achieve the effect of harmless and resource-based disposal, avoiding manual operations, and low-cost environmental protection treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

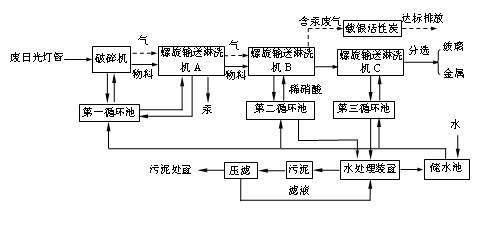

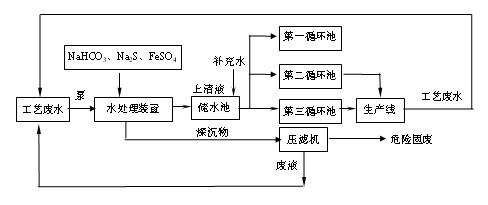

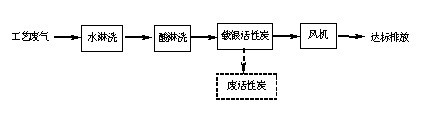

[0024] Example: See the accompanying drawings, the mercury-containing waste lamp tubes are first sent to a crusher submerged in water for crushing, and after crushing, they are discharged and sent to the first upward oblique spiral conveying washing machine that is sealed and connected (both materials and waste gas are closed) A, after water immersion-leaching, wherein the water-insoluble elemental mercury is collected by the bottom collecting mercury bottle 18, and after separating the water, it enters the second-stage upper oblique spiral conveying washing machine B with a sealed connection, and the concentration is 20wt % nitric acid solution immersion-leaching, after separating the acid, enter the third-stage upper oblique spiral conveying rinsing machine C which is sealed and connected, immerse-rinsing with water, separate the water, and then enter the magnetic separation separator to separate the metal lamp head. Mercury-containing waste gas is generated during the treat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com