Synchronous ditching ridging fertilizing seeder for paddy field

A technology of ridge fertilization and seeding machine, which is applied in the direction of fertilizer and seeding equipment, fertilization device, excavation/covering of ditches and holes, etc. It can solve the problems that chemical fertilizers cannot be covered, fertilization and seeding cannot be performed simultaneously, and they are scattered into the air, so as to improve Effects of fertilizer use efficiency, saving water in rice production, and saving fertilizer usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below in conjunction with the accompanying drawings.

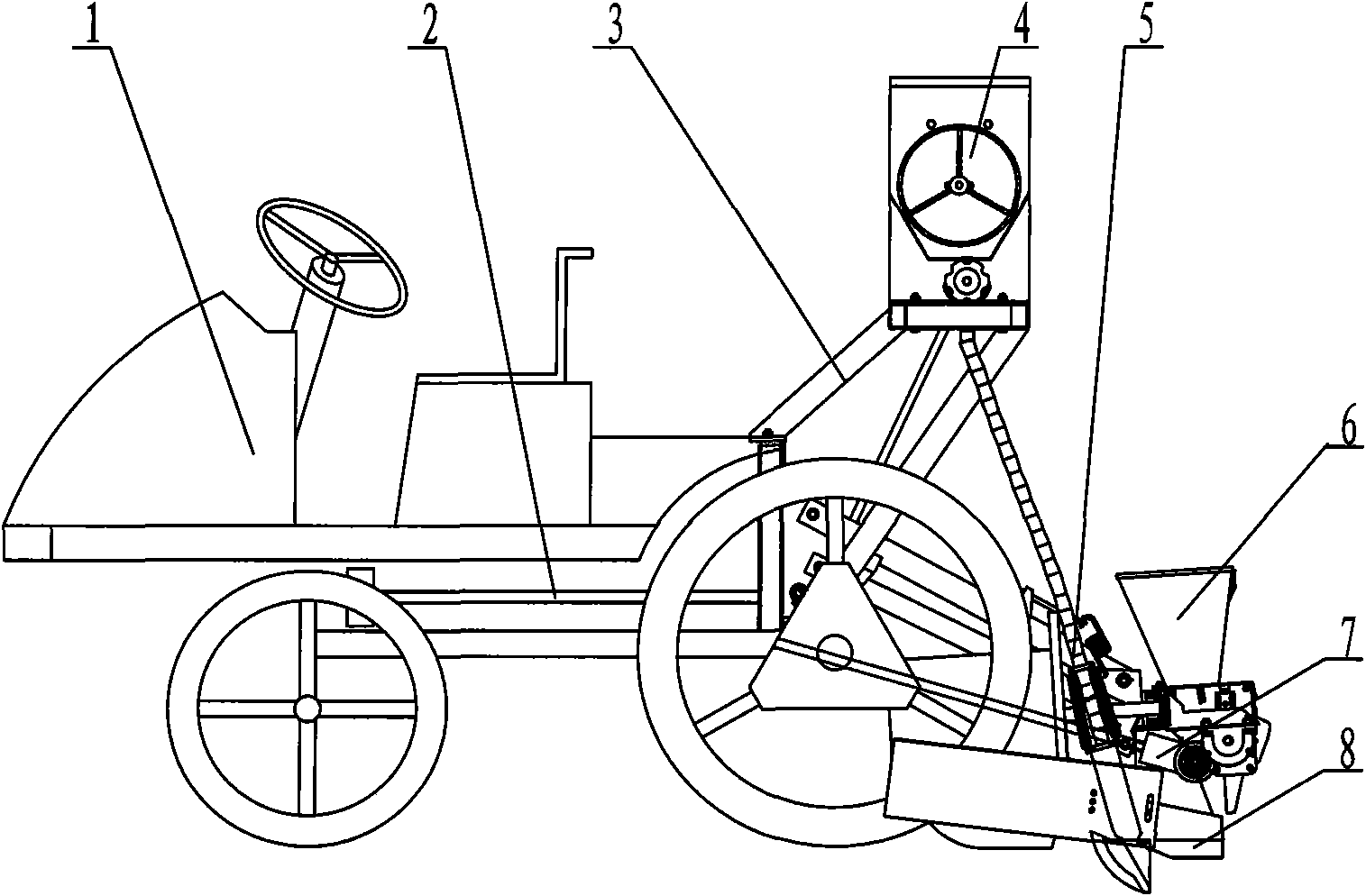

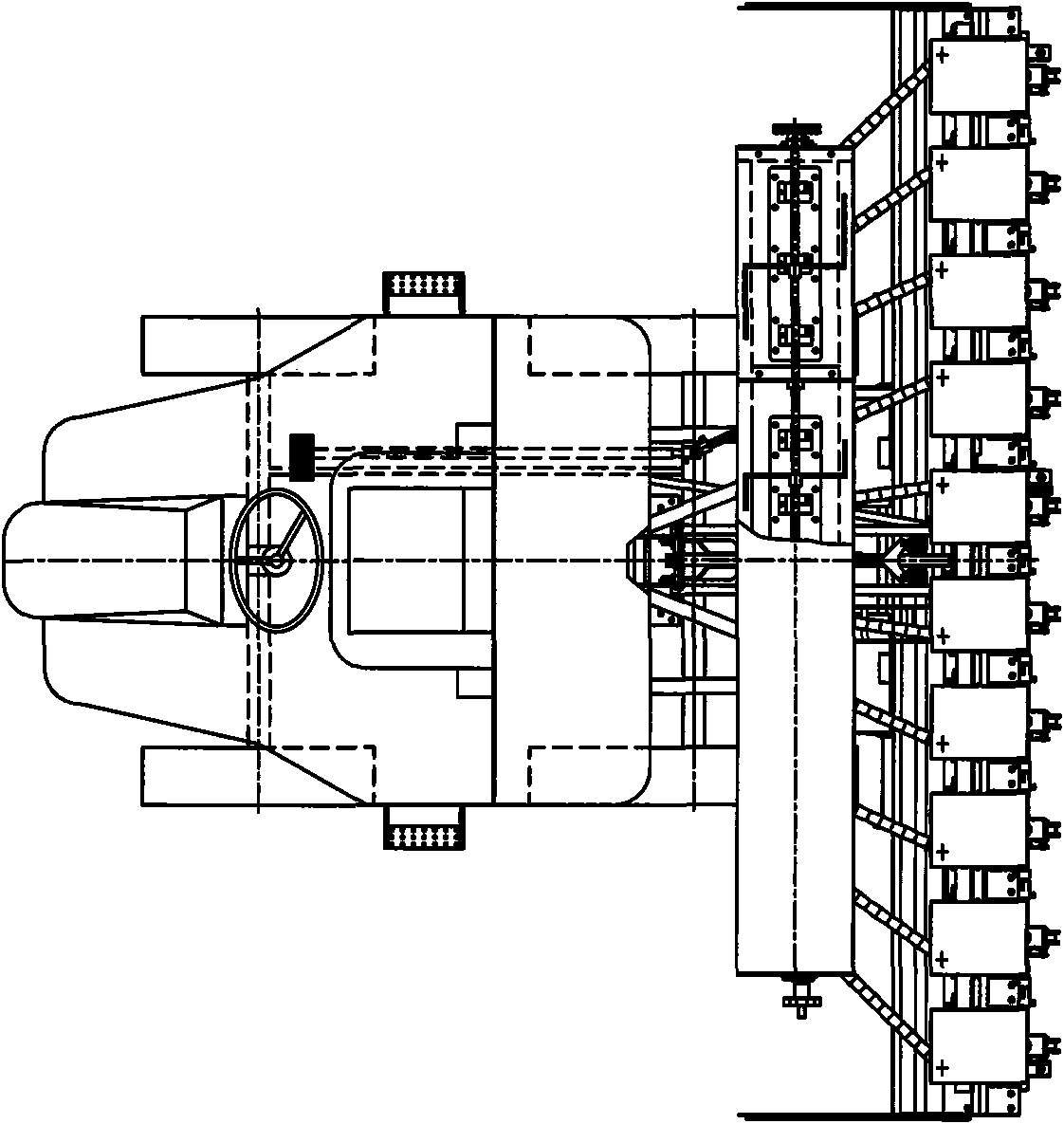

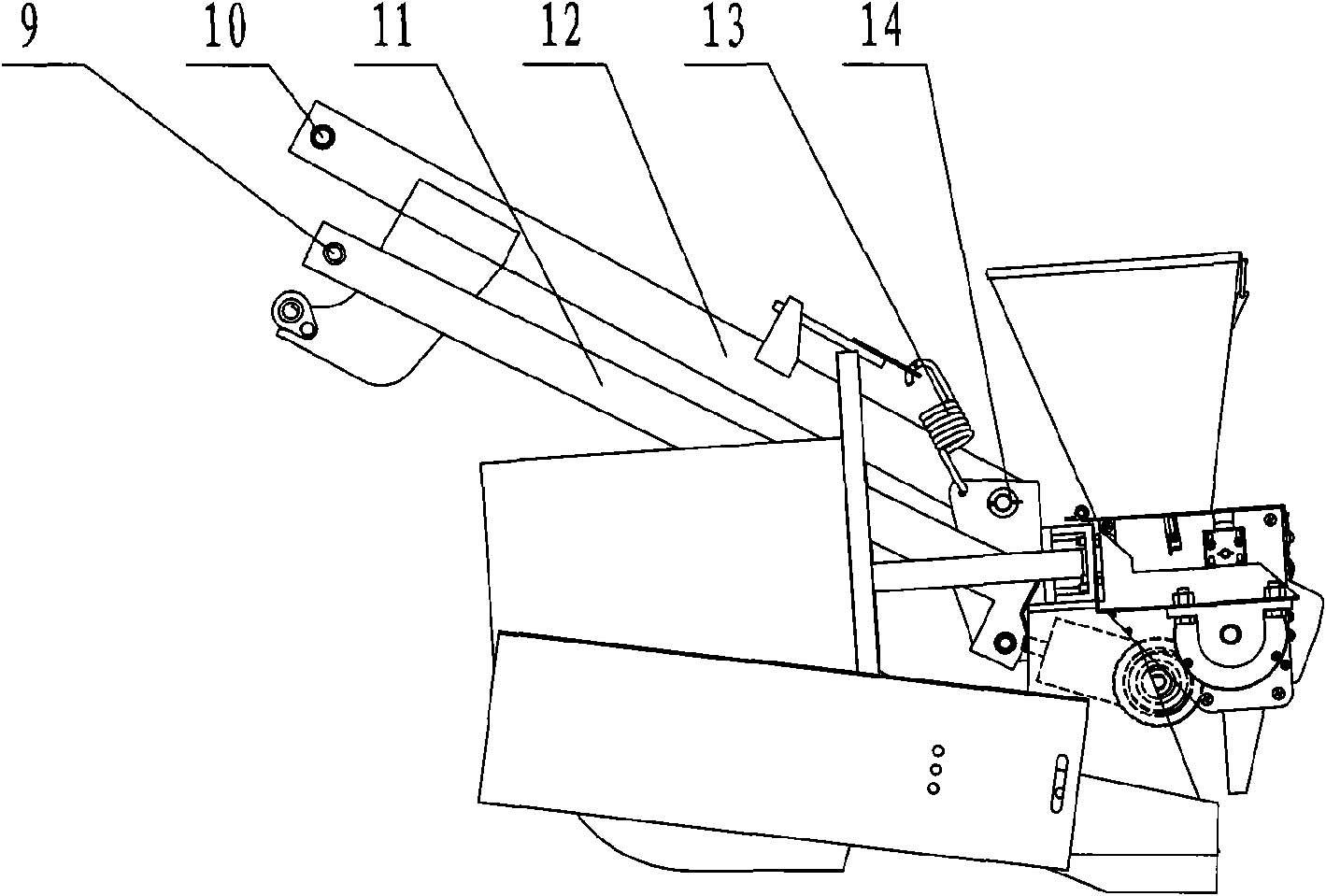

[0032] Such as figure 1 The shown is a paddy field synchronous ditching, ridging, fertilizing and seeding machine that can be used for direct seeding of rice. The head of the ride-on rice transplanter is used as the power machine, including the fertilizer discharge power transmission system 2 installed on the power machine 1, the fertilizer box connecting device 3, Fertilizer discharge system 4, suspension device 5, seeding system 6, seeding power transmission system 7 and ditching device 8. The rear portion of the power machine is equipped with a suspension device 5 and a fertilizer box connection device 3, a seeding system 6 is installed through the suspension device, a fertilizer discharge system 4 is installed through the fertilizer box connection device 3, and a ditching device is installed under the seeding system; The device can lift or lower the seeding syst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com