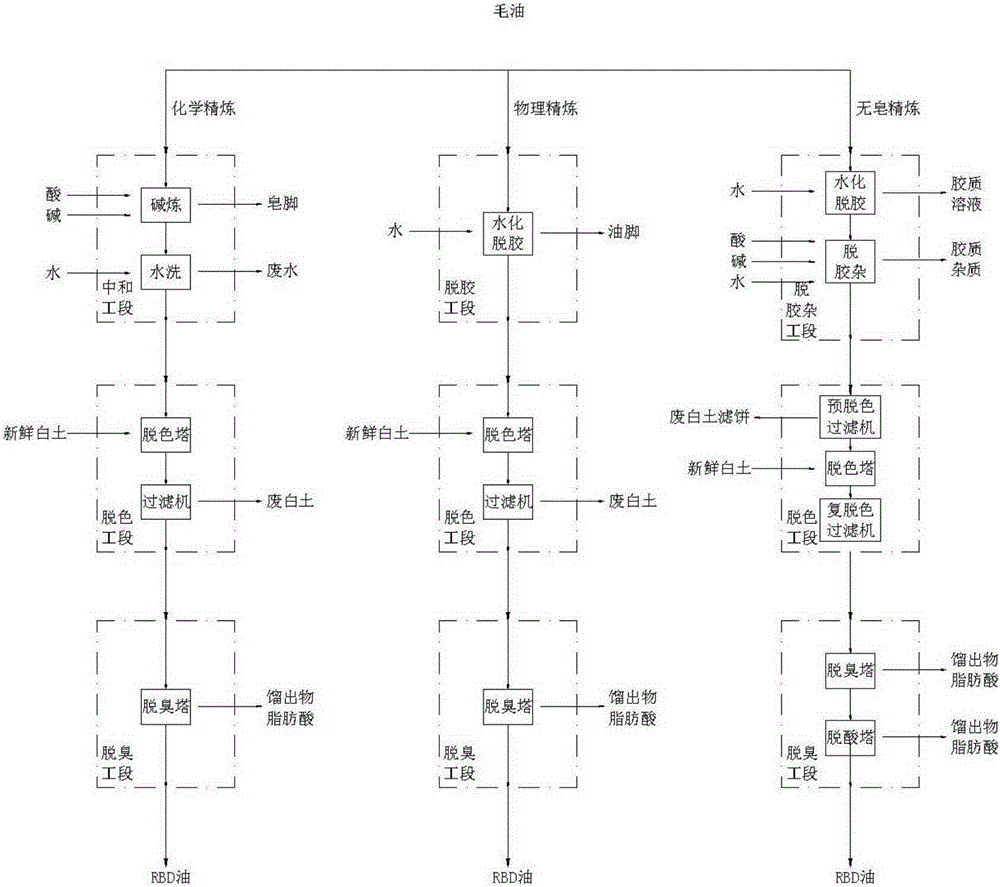

Edible plant oil non-soap refining method

A technology of edible vegetable oil and crude oil, which is applied in the direction of fat oil/fat refining and fat production, etc. It can solve the problems of no economical and reliable dephosphorization process, metal ion color reversion, and incomplete dephosphorization, so as to achieve excellent refining effect and improve Yield, the effect of reducing investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Raw materials: Crude soybean oil extracted from Zhizhiyuan Oil Factory in Nansha, Guangdong, acid value 1.69mgKOH / g, phosphorus content 319ppm, color red 7.0 / yellow 60.

[0041] Miscellaneous degumming process:

[0042] The crude soybean oil extracted at room temperature (impurity 99.5%; Add alkali and hot water (85 ℃), add alkali amount to add citric acid content 0.3~0.8 times, with No soap stock is produced; add hot water with an amount twice the weight of phospholipids, after adding water, pass through a plate heat exchanger for heat exchange and cooling, and the water-oil mixture cooled to 30°C enters the flocculation reaction tank. The flocculation reaction tank is equipped with a stirrer with a rotation speed of 35 rpm, and the residence time of the flocculation reaction is 90 minutes. It is pumped out through the discharge pump of the flocculation reaction tank, the reaction mixture is exchanged with the mixture entering the flocculation reaction tank through a ...

Embodiment 2

[0053] Raw material: Crude corn oil leached from Shandong Sanxing Corn Industry Technology Co., Ltd., acid value 4.65mgKOH / g, phosphorus content 306ppm, color red 6.5 / yellow 65.

[0054] Miscellaneous degumming process:

[0055] Extract crude corn oil (containing impurities 99.2%; add alkali and hot water (90 ° C), the amount of alkali added is 0.5 to 0.9 times the content of phosphoric acid added, so as not to produce The soap foot shall prevail; add hot water with an amount of 1.5 times the weight of phospholipids, after adding water, pass through a plate heat exchanger for heat exchange and cooling, and the water-oil mixture cooled to 33°C enters the flocculation reaction tank. The flocculation reaction tank is equipped with a stirrer with a rotation speed of 40 rpm, and the residence time of the flocculation reaction is 75 minutes. It is pumped out through the discharge pump of the flocculation reaction tank, and the reaction mixture is exchanged with the mixture entering...

Embodiment 3

[0066] Raw materials: wool cottonseed oil pressed by Shandong Baizheng Biotechnology Co., Ltd., acid value 1.37mgKOH / g, phosphorus content 237ppm, color red 5.5 / yellow 30.

[0067] Miscellaneous degumming process:

[0068]Pressed wool cottonseed oil (impurity 99.6%; Add alkali and hot water (83 ° C), and the amount of alkali added was 0.6 to 0.9 times the phosphoric acid content, so as not to produce soap The foot shall prevail; add hot water with an amount of 1.7 times the weight of phospholipids, after adding water, heat exchange and cooling through a plate heat exchanger, and the water-oil mixture cooled to 35°C enters the flocculation reaction tank. The flocculation reaction tank is equipped with a stirrer with a rotation speed of 45 rpm, and the residence time of the flocculation reaction is 60 minutes. It is pumped out through the discharge pump of the flocculation reaction tank, the reaction mixture is exchanged with the mixture entering the flocculation reaction tank...

PUM

| Property | Measurement | Unit |

|---|---|---|

| smoke point | aaaaa | aaaaa |

| smoke point | aaaaa | aaaaa |

| smoke point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com