Method for producing mud fermentation pitless fragrant liquor

A technology of Luzhou-flavor liquor and its production method, which is applied in the field of no-mud pit Luzhou-flavor liquor production, which can solve the problems of difficult food safety control, low resource utilization rate, and low production efficiency, so as to promote innovation and development and reduce labor intensity , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

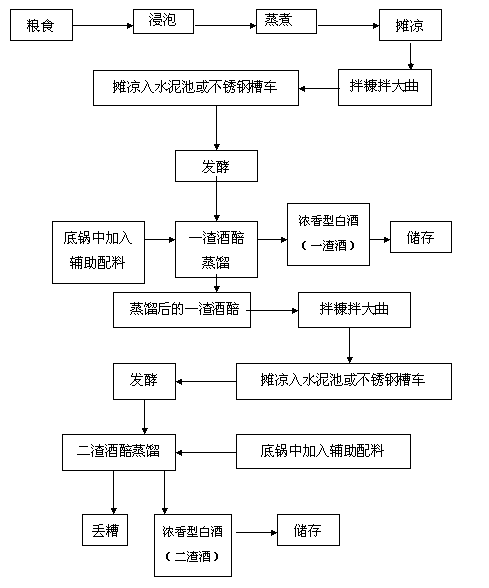

[0039] A method for producing non-mud pit Luzhou-flavor liquor, the method comprising the following steps:

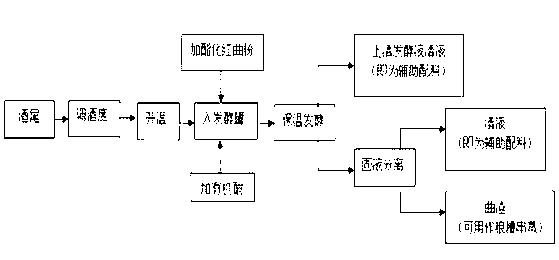

[0040] 1) Preparation of auxiliary ingredients, the process flow chart is as follows figure 2 Shown:

[0041] Adjust the alcohol content of the tail of the liquor brewed by the solid-state method to 10-20% Vol with 95% vol edible alcohol, then raise the temperature to 30°C, pump the wine tail with adjusted alcohol content and temperature into the fermenter,

[0042] Add organic acid and esterified red yeast rice powder to the fermenter in sequence, stir evenly, keep it warm and ferment for 28 days, and control the fermentation temperature at 32°C.

[0043] Collect the fermented and mature supernatant fermentation liquid to prepare auxiliary ingredients;

[0044] After the solid-liquid mixture after collecting the supernatant fermentation liquid is separated by a solid-liquid separator, the collected liquid is the auxiliary ingredient, and the koji residue left after ...

Embodiment 2

[0051] A method for producing non-mud pit Luzhou-flavor liquor, the method comprising the following steps:

[0052] 1) Preparation of auxiliary ingredients, the process flow chart is as follows figure 2 Shown:

[0053]Adjust the alcohol content of the tail of liquor brewed by the solid-state method to 10-20% Vol with 95% vol of edible alcohol, then raise the temperature to 35°C, pump the wine tail with adjusted alcohol content and temperature into the fermenter,

[0054] Add organic acid and esterified red yeast rice powder to the fermenter in sequence, stir evenly, keep it warm and ferment for 20 days, and control the fermentation temperature at 34°C.

[0055] Collect the fermented and mature supernatant fermentation liquid to prepare auxiliary ingredients;

[0056] After the solid-liquid mixture after collecting the supernatant fermentation liquid is separated by a solid-liquid separator, the collected liquid is the auxiliary ingredient, and the koji residue left after th...

Embodiment 3

[0066] A method for producing non-mud pit Luzhou-flavor liquor, the method comprising the following steps:

[0067] 1) Preparation of auxiliary ingredients, the process flow chart is as follows figure 2 Shown:

[0068] Adjust the alcohol content of the tail of liquor brewed by the solid-state method to 10-20% Vol with 95% vol of edible alcohol, then raise the temperature to 32°C, pump the tail of wine with adjusted alcohol content and temperature into the fermenter,

[0069] Add organic acid and esterified red yeast rice powder to the fermenter in sequence, stir evenly and keep it warm for 22 days. The fermentation temperature is controlled at 33°C.

[0070] Collect the fermented and mature supernatant fermentation liquid to prepare auxiliary ingredients;

[0071] After the solid-liquid mixture after collecting the supernatant fermentation liquid is separated by a solid-liquid separator, the collected liquid is the auxiliary ingredient, and the koji residue left after the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com