Wet-method dust removal device for powder grinding machine

A wet dust removal and pulverizer technology, which is applied in the direction of removing smoke and dust, combined devices, separation methods, etc., can solve the problems of poor dust removal effect of bag filter, high production cost of dust collector, and difficult dust wetting, etc. The effect of good dust removal effect, low cost and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

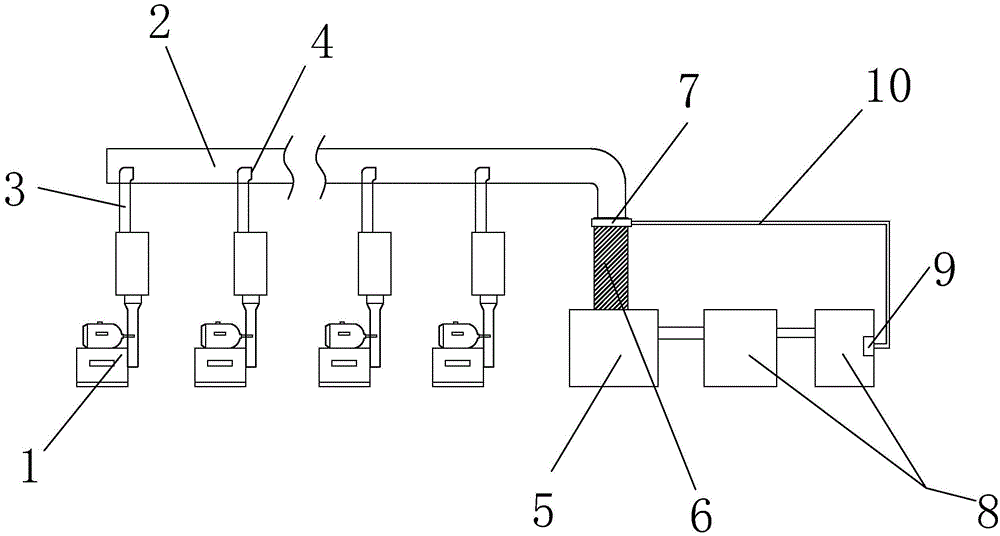

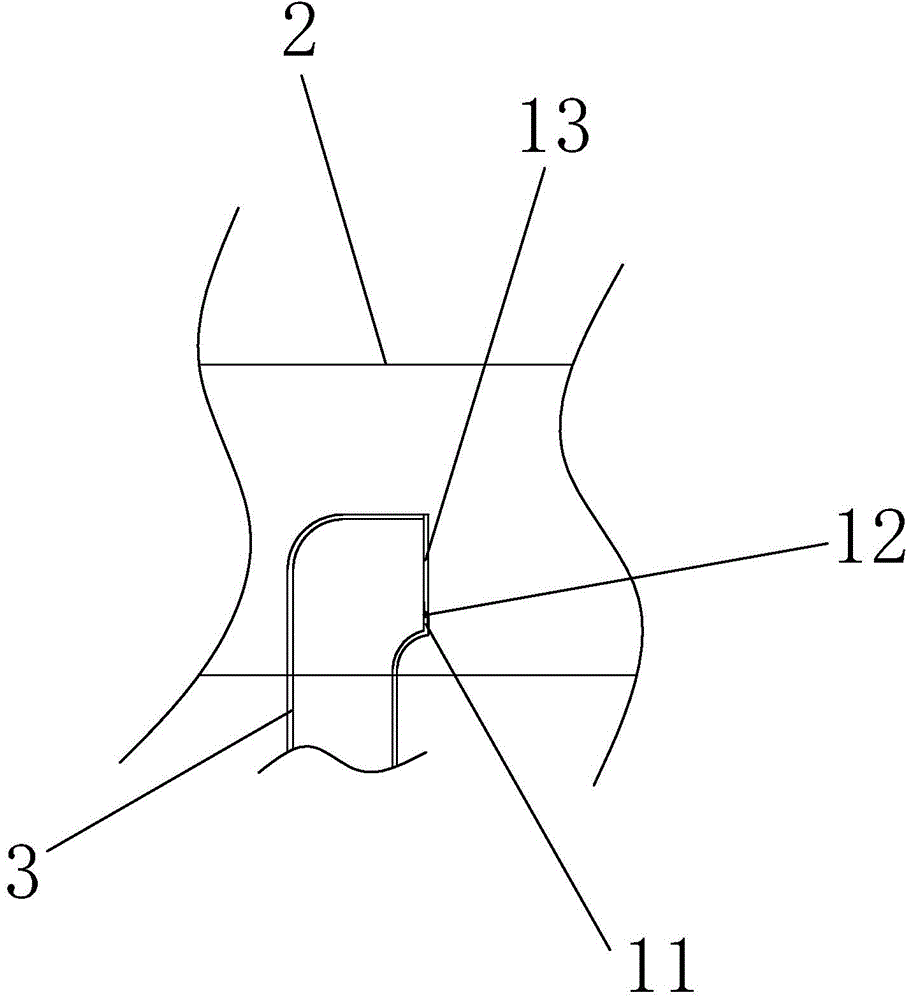

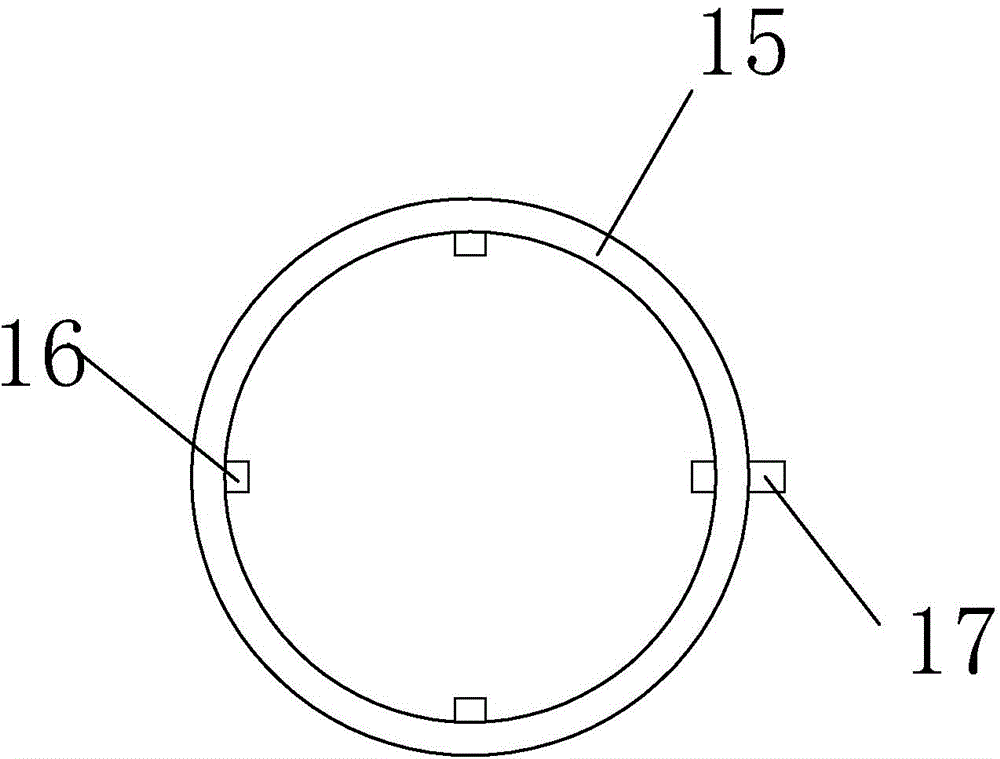

[0024]A wet dust removal device for a pulverizer, comprising four induced draft fans 1 and dust guide pipes 2, the induced draft fan 1 is provided with a dust discharge pipe 3, and the induced draft fan 1 communicates with the dust discharge pipe 2 through the dust discharge pipe 3 , the starting port of the dust guide pipe 2 is a closed structure, the opening of the dust discharge pipe 3 is set inside the dust guide pipe 2, and the openings of all the dust discharge pipes 3 are set in the same direction, the direction of the opening is away from the starting end, and the opening is set There is a one-way valve 4 to prevent dust from flowing back into the dust discharge pipe 3. The one-way valve 4 includes a fixed block 11 arranged at the opening. The fixed block 11 is connected to a baffle 13 through a torsion spring 12. The upper end of the baffle 13 is It is higher than the position of the upper end of the opening of the dust discharge pipe 3 . The end of the dust guide pip...

Embodiment 2

[0027] Compared with embodiment 1, the difference of embodiment 2 is:

[0028] The starting end of the dust guide pipe 2 is provided with a blower 14 , and the blower 14 communicates with the dust guide pipe 2 . The air blower 14 can provide air flow in the dust guide pipe 2, so that the inside of the dust guide pipe 2 can be kept unimpeded, so as to prevent dust from being deposited in the dust guide pipe 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com