Method for recovering methyl chloride in discharged tail gas of glyphosate / dimethyl phosphate production

A technology of dimethyl phosphite and a recovery method, which is applied in the field of recovery of methyl chloride in tail gas, can solve problems such as reducing economic income, environmental air impact, etc., to ensure stable operation, improve production efficiency, and have significant environmental and economic benefits. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

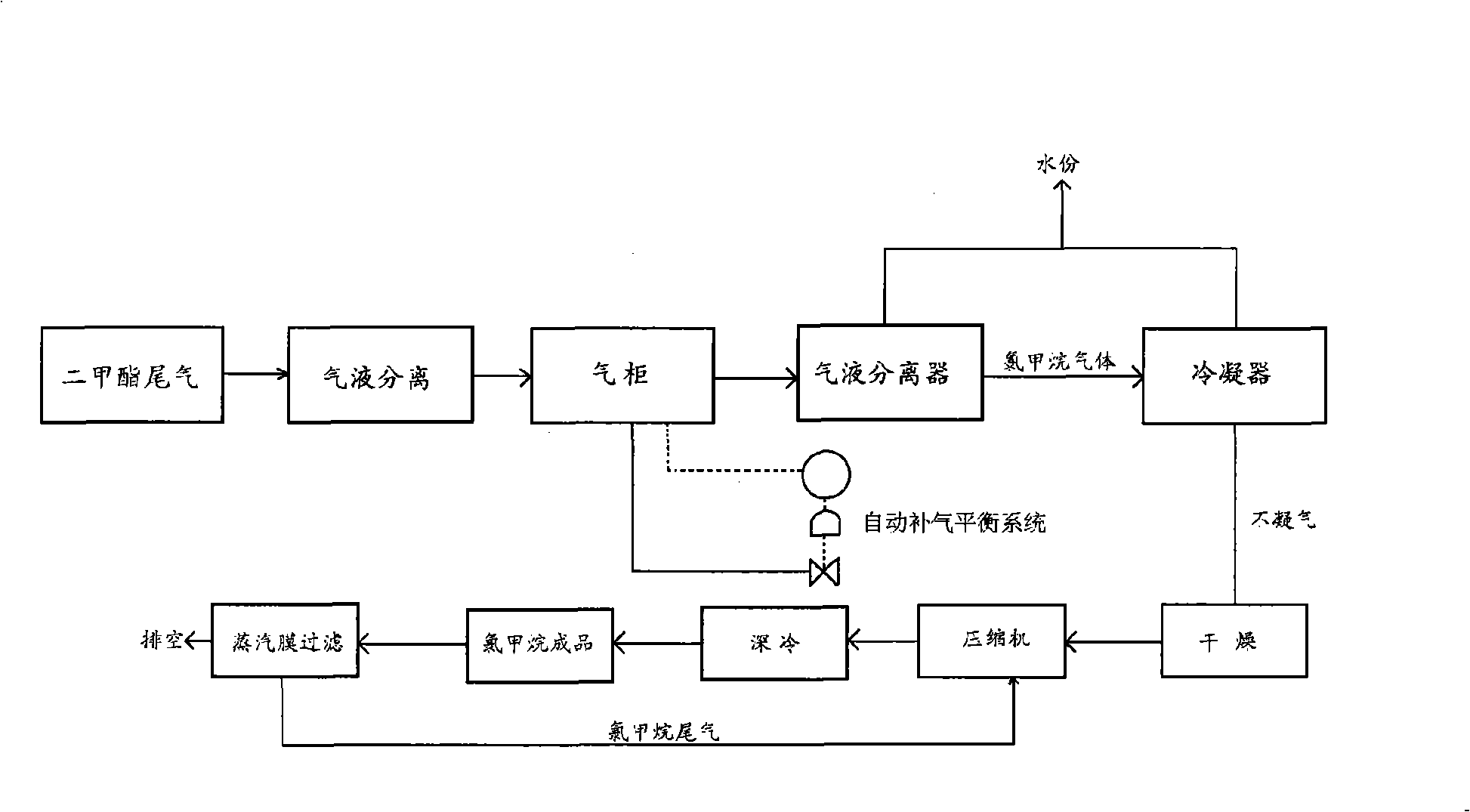

[0010] The tail gas from the glyphosate / dimethyl phosphite production process enters the gas-liquid separator through the buffer tank to separate the water and then enters the cabinet; the methyl chloride in the gas cabinet enters the condenser through the gas-liquid separator, and the condenser The condensing temperature is -15°C to condense and separate the water in the gas. The chloromethane gas from the condenser passes through a three-stage water washing tower, a first-stage alkali washing tower, and a fourth-stage concentrated acid tower for drying treatment, and the chlorine is removed by water washing. The methanol component in the methane gas, the acidic component in the methyl chloride gas is removed by alkali washing, and the moisture in the methyl chloride gas is removed by concentrated acid drying. The specifications of each tower are ∮800×8000, and ∮38PP stepped ring is installed inside, and wire mesh corrugated packing is installed on the top to increase the abso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com