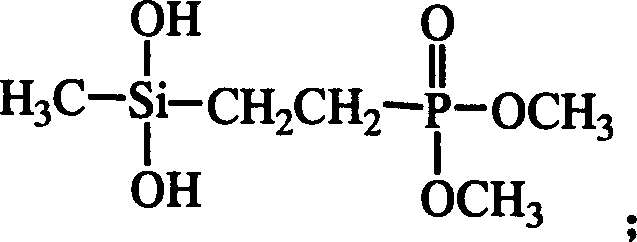

Silicon phosphonate containing fire rotardant and its synthesis method

A technology of silicon phosphonate and synthesis method, which is applied in textiles, papermaking, fiber treatment, etc., and can solve problems such as hard hand feeling, large loss of fabric strength, environmental and human health hazards, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

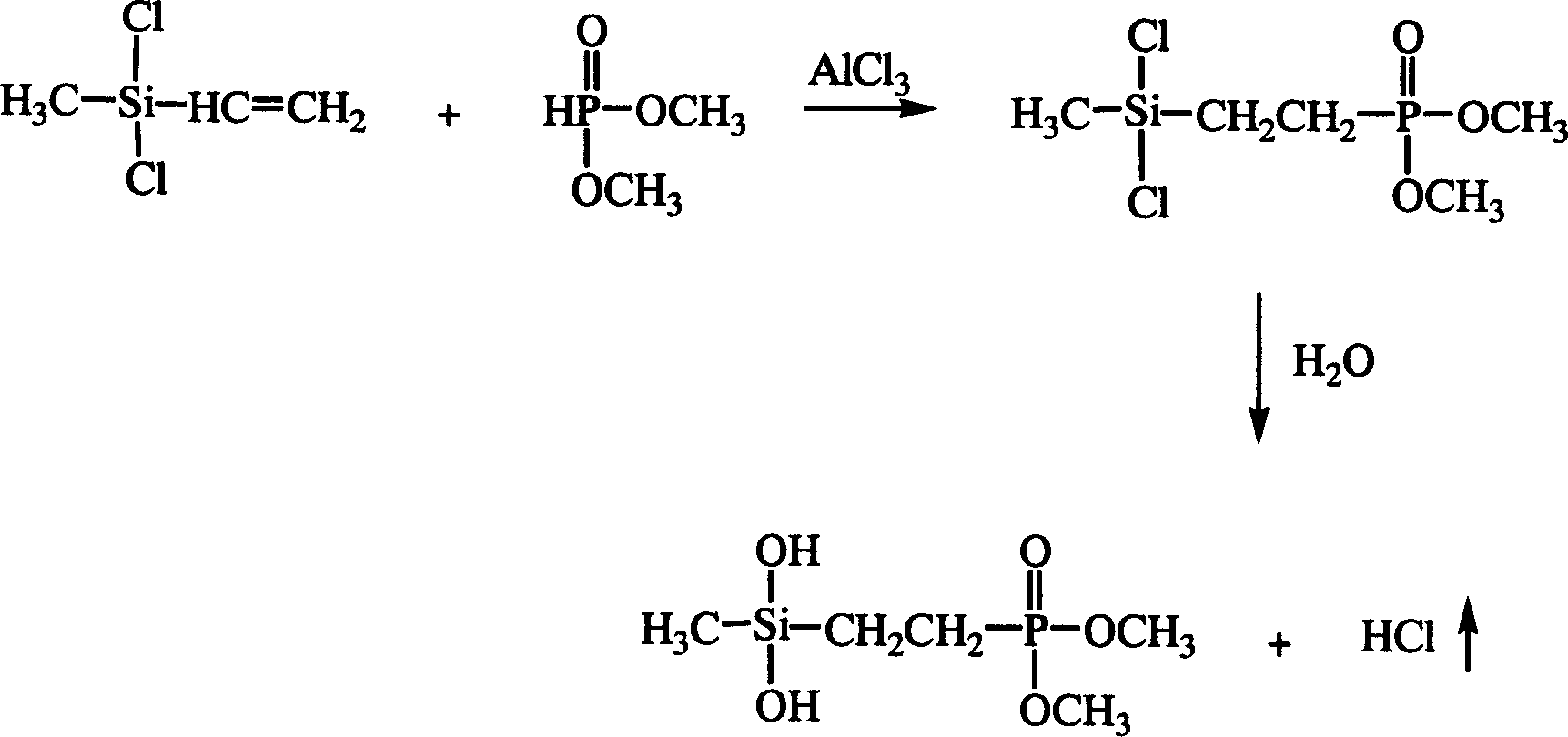

Method used

Image

Examples

Embodiment 1

[0016] Example 1: Take 68.5g of methyl vinyl dichlorosilane in a 500ml round bottom flask, add 200ml of dichloroethane and stir well. Then 60.5 g of dimethyl phosphite and 3 g of pyridine were added as catalysts. Stir at 50°C for 24 hours under nitrogen protection. Then the temperature was raised to 90°C and refluxed for 4 hours, and the fraction at 150-155°C and -0.099mPa was collected by molecular distillation, and 20 g of distilled water was slowly added dropwise to the fraction to react, and then the temperature was raised to 75°C to continue the reaction for 4 hours. After cooling down to room temperature, 200ml of distilled water was added into the reaction system, and the phases were separated after fully stirring. The distilled water phase obtained a light yellow viscous liquid with a yield of 82%. The analysis test results are as follows:

[0017] Fourier infrared: 3440cm -1 、2968cm -1 、1633cm -1 、1271cm -1 、1122cm -1 、1036cm -1 、779cm -1 characteristic peaks...

Embodiment 2

[0019] Embodiment 2: other is the same as embodiment 1, uses triethylamine instead to make catalyst, yield 70%.

Embodiment 3

[0020] Embodiment 3: other are the same as embodiment 1, change dimethyl phosphite add-on to be 120.0g (1.0mol) and 3g aluminum chloride to make catalyst, dichloroethane consumption is 250ml, yield 87%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com